| THE INDUSTRIAL RAILWAY RECORD |

© OCTOBER 1973 |

BRADFORD WATERWORKS NARROW GAUGE

SYDNEY A. LELEUX

(Photographs by the author).The standard gauge Nidd Valley Light Railway, which was constructed and operated by Bradford Corporation Water Department during the construction of the Angram and Scar House reservoirs, is well known. Not so well known are the other 2ft gauge railways operated by the Department of which two were still in daily use in 1970.

Chellow Heights

I discovered these railways when I took some of my pupils to Chellow Heights Waterworks, Haworth Road, Bradford (Grid Reference SE 117351). The original works were completed in 1900, and have been extended several times since to meet increasing demand, and a current modernisation scheme is due for completion by about 1975. The railway here was abandoned at the end of June 1972 when the last of the slow sand filter beds was taken out of commission. In all there were ten filter beds in two parallel blocks of five; each bed was about fifty yards square. The floor consisted of a 2ft 6in deep layer of sharp sand laid on gin of gravel above a network of tiles and drains. Raw water flowed into the bed, then passed through the sand which filtered off any suspended matter which caused turbidity. Each bed had to-be drained periodically so that the top layer of dirty sand

– 'schmutzdecke' - which clogged the bed could be removed, washed and replaced. It was vital for the sand floor to be kept level to maintain even filtration and to ease skimming off the dirty sand with a long shovel or scoops. Usually only the top ¼in‑½in was removed, but this amounted to about 25 tons per bed, while an uneven surface could result in up to 50 tons being changed.The railway first laid in 1900 was used to carry dirty sand to a washing plant. The layout was a 'U' with one group of beds beside each arm and the washing plant at the base. Each bed had a concrete gantry sloping at about 1 in 10 built against a dividing wall to carry tracks down to the floor of the bed. The main track was laid with 20lb rail on steel sleepers embedded in concrete beside the western beds. At the washer and by the eastern beds it was laid on the ground with intermediate wood sleepers as well. Curves were often checkrailed. Heavy cast turntables, made by the Summerbridge Foundry, gave access to the bed gantries. Tracks on the gantries were permanent, but on the bed floor 14lb rail was laid as required, with turning plates at junctions. The turning plates were of two types, one being a turntable with no rails on the table itself. These were used at the foot of the gantry and had been used in the beds, but suffered from the twin disadvantage of weight and the need to be laid into the track. Consequently the works designed a much lighter table which could be laid on top of existing track. A narrow steel plate, flanged to locate it on the rails, supported a light framework of steel angle. The vertical sides of the angle rested against the outer face of the head of the running rail, thus locating the table so that the truck could run up on to the horizontal sides of the angle. When the truck was central on the table its weight tilted the framework so it was horizontal, thus lifting the angle clear of the rails and permitting the table to turn.

When a bed was to be cleaned it was divided into squares and the sand shovelled into small piles, beginning in the corner furthest from the gantry so that the dirty scrapings were not carried across clean sand. Temporary tracks were laid as required, from the foot of the gantry. Trucks were loaded by hand and pushed to the foot of the gantry, up which they were pulled by a steel rope.

At first, the rope was wound in by a water powered winch mounted on a wagon, but following the introduction of locomotives, the winch fell into disuse, but was not scrapped until 1969. The winch was driven through a clutch by a Pelton wheel which was connected to a fire hydrant beside the bed. The continuously rotating wheel used large quantities of water which discharged to waste. More recently the steel rope was fastened to the rear of the pair of wagons, taken round a pulley mounted on the ground and hooked to the locomotive, which then reversed until the rear wagon was on the turntable. The wagons were then turned into the main line and propelled to the washer. Wagons of clean sand were then collected and run into the bed with the locomotive acting as brake. In earlier days, wagons had been pushed to and from the washer by hand.

In 1928 a new rapid gravity filter house and beds were built. These beds, each only 24ft long and 14ft wide, were filled with 1ft 8in of gravel in layers of increasing fineness, from a base of 2in of pebbles to a top layer of sand 2ft 1in thick. The beds were cleaned by blowing compressed air up through the bed to put most of the dirt into suspension, the dirty water being collected and returned to the incoming flow for treatment. However, the beds required periodic manual cleaning, and to assist this a gantry was built across each of the beds in 1938. At first each gantry was built on two lines of telegraph poles spanned by sleepers carrying the track, but later a concrete gantry replaced the wooden structure. Since the gantry floor was about 7ft above the ground a portable steel ramp was built which could be moved to give access to either gantry. Wagons used to be hauled up the steel ramp to the rapid gravity filters by a compressed air winch, but latterly a locomotive, wire rope and pulleys were used.

Ruston & Hornsby 198287 at Chellow Heights. Note the piles of dirty sand in the filter bed, ready for loading into the two trucks, and the temporary track in the filter bed. July 1970.

The disused Ransomes & Rapier diesel (DL 71) at Chellow Heights, July 1970.

Alum blocks used to be slaked in tanks in the filter-house and the resulting solution was then added to incoming water to assist in the precipitation of suspended matter. The store still stands in front of the rapid gravity filter-house. The blocks were lowered on to flat wagons and pushed to a lift in the filter-house; this rail system was independent of the main one.

Rolling stock consisted of a maximum of twenty jubilee side tipping wagons. In July 1970 there were ten wagons and an underframe converted to a flat wagon to carry permanent way materials and a 5cwt electric crane. The crane was built by a water works fitter in 1956, to assist in the repair and maintenance of the rapid gravity filters and to remove sludge from the adjoining sedimentation tanks (now also disused). The basis of the crane was a skip chassis, with the crane body made from steel channel and angle. A sheet metal cover protected the electric motor, which obtained power from the filler house through a trailing flex.

The first locomotive at Chellow Heights was a large Simplex from the Scar House reservoir construction railway. It was found to be too wide and heavy (about 6½ tons) and was sent to Hewenden reservoir. Records indicate that it was built in 1932 and possibly numbered 71. It was replaced by a 3 ton Ransomes & Rapier diesel, number DL 71, which came from Gilstead filterbeds in 1952. This was given a heavy repair during 1965‑66 and used until early 1969, when it was withdrawn and stored in the locomotive shed (a wooden garage) because of the difficulty in obtaining spares. Livery was dark green and at one time it was fitted with a cab. Several half hearted attempts were made to preserve this locomotive, but failing any definite offer it was sold to Crossley Bros of Shipley for scrap in the summer of 1971, and was soon cut up.

The Rapier was replaced by a 7ton 44/48hp Ruston & Hornsby diesel, works number 198287. It was delivered new to the Air Ministry, Harpurhill, transferred to Burtonwood in 1957, then went to Fauld for a short spell in 1969, finally returning to Burtonwood for a while before being sold. It retained its Air Ministry number (AMW 197) on a small brass plate by the cab door and was fully flameproofed. Livery was a pale blue-grey and red. It was a much larger locomotive than the Rapier but was available when the need arose, and was obtained cheaply. Its weight has damaged the track and in mid‑1970 it was due to be lightened by stripping off all non‑essential parts.

When, in the past, the locomotive has broken down, replacements have either been borrowed from Thornton Moor Waterworks or hired from dealers. One hired locomotive was a Lister, but this was found much too light for the job. Other hirings have been from Walker & Partners, Glasgow (agents), who supplied 'S 141' (Ruston & Hornsby 462361 of 1960) to Thornton Moor. It was used here between 3rd August 1965 and 3rd February 1966 to replace their Ruston, which was working at Chellow Heights while the Rapier was under repair. (Chellow Heights also repaired the Ruston whilst it was on loan from Thornton Moor.) Walker's supplied a Simplex to Chellow Heights a few months later, between 26th May 1966 and 28th November 1966.

The railway was in daily use in 1970, but was being run down prior to its eventual replacement. Latterly it was necessary to lift rail from little used sections - for example, the rapid gravity filter gantries

– to keep other sections operating. By 1970 all five of the eastern beds had been taken out of service and the main line cut back. Complete closure came officially on 30th June 1972, when a reservoir was about to be built on the site of the last slow sand filter beds.Thornton Moor

This works, situated on the bleak hillside about a mile west of the village of Denholme at SE 051334, still retains a railway. The works, which are about one hundred and thirty years old, consist of a large reservoir fed by conduits which run seven miles across the slope of the hill tapping streams en route, and a group of four sand filter beds. The beds consist of 3ft of sand, 1ft of pea gravel and 3ft 9in of graded stones

– 'peas, potatoes and turnips' according to an old drawing! At first the sand was washed in special tanks in the centre of the beds, but later a sand washing plant was built and a railway laid to serve it.The line ran eastwards across the southern ends of the beds to a compound where there was a loop round the washer. The track terminated in a small stone loco shed. Curves on the loop were checkrailed, as was also a bend at the end of the beds and a level crossing over a works road. Unlike Chellow Heights the gantry into the beds was a temporary wooden structure, again sloping at about 1 in 10. Whereas Chellow Heights had turntables permanently laid in the main line, here a turntable was only laid when required. A shallow concrete 'saucer' was provided by each bed for a turntable base, but normally the hole was spanned by a 3ft length of track. The main line was made up of 20lb rail on wood sleepers in concrete, with very light portable tracks in the beds.

In July 1970 rolling stock comprised nine Hudson skips and two flats. Motive power used to be a horse, but about 1940 a battered 16/20hp Ruston & Hornsby diesel locomotive of early 1930s vintage was obtained 'as scrap'. It had no worksplate; this was possibly lost when a Wheatley (Leeds) engine was fitted in early 1966. It was cabless and had a bright blue livery with white lettering 'L2 Bradford Water'. As already mentioned, in 1965‑66 they had a loco from Glasgow when L2 was sent to Chellow Heights for repairs. Following the closure of the railways at Chellow Heights the big Ruston was transferred to Thornton Moor. It is kept in a shed - an ex BR van body - at the western end of the line, but its weight may prove a problem here.

Single wagons were hauled from the beds by a wire rope passed round a temporary pulley and fastened to the locomotive (or horse). The dirty sand was either taken to the washer (five or six wagons at a time) or to dumps beside the beds for storage if the beds were being completely emptied.

A view from the filter bed at Thornton Moor showing L2 (Ruston & Hornsby) in the background about to haul a loaded skip out of the bed up the temporary wooden gantry. Note the home made turntable spanning the track which runs across the picture. July 1970.

Gilstead Filterbeds

These are situated at Bingley (SE 120395). There was a railway, presumably similar to those at Chellow Heights and Thornton Moor, which was replaced when the beds were mechanised. A small, light Ransomes & Rapier skimmer loaded the sand into a small dumper. The sand was then either washed at the side of the bed and returned immediately, or grabbed out and taken to a central washer, in which case the sand might not be replaced until repeated skimming had left only 12in and then all the sand was returned at once. The Rapier diesel locomotive worked here from 1948 to 1952, when it was transferred to Chellow Heights. In 1970 the loco still carried a plate showing that it was supplied by the 600 Group (George Cohen, Sons & Co Ltd), to whom it had been delivered new in 1936.

Hewenden Reservoir

This is located at SE 074355, a mile north of Denholme beside the GNR Keighley branch. It appears to have had a temporary railway associated with some repairs to the reservoir, since the Chellow Heights Simplex was transferred here for a period before being sold - and there were no filter beds here.

I am grateful to numerous waterworks employees for answering my questions about their railways, especially Messrs J E Bentley and J Delaney, both of Chellow Heights, and Mr Roper of Thornton Moor: and to Mr S Asquith, Waterworks Engineer, for permission to publish this description.

'If the discovery had been made at the present time, it would have been possible to transport the objects on a tarmac road from the Valley of the Kings to the river or perhaps by helicopter to Luxor airport on the east bank, but fifty years ago no such amenities existed. Carter had to choose between transport by camel, by porters and by Decauville railway and he decided on the railway. The operation would not have been difficult if he had possessed enough track to cover the distance, but his supply amounted to no more than a few lengths of railway line which had to be lifted, after the trucks loaded with boxes of objects had been pushed forward over them, and relaid farther forward in readiness for the next move. With a gang of fifty men a rate of more than a third of a mile an hour was maintained and the whole journey from the tomb to the river bank occupied no longer than fifteen hours. Carried out in the heat of summer with iron rails which were almost too hot to touch, it was a very remarkable achievement. Seven days after the boxes were loaded on a steam vessel belonging to the Antiquities Service of the Egyptian Government they were safely delivered to the Cairo Museum.'

(Extract from the Guide to the Tutankhamun Exhibition held at the British Museum in 1972. An illustration of the operation in progress also appears in the Guide.

– PS)

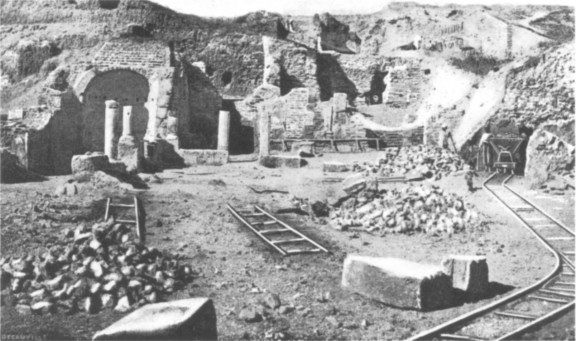

Decauville advertised the use of their light railway system as an aid to archaeological 'digs': A view from their 1916 catalogue shows such a system but does not identify the location. (courtesy M. Swift)