| THE INDUSTRIAL RAILWAY RECORD |

© OCTOBER 1973 |

THE END OF AN ERA AT SHELTON BAR

ALLAN C. BAKER

Thursday, 30th March 1972, was a historic occasion in the history of the British Steel Corporation's Shelton Works, Stoke-on-Trent, for it marked the departure of their last steam locomotive. The works, formerly Shelton Iron & Steel Ltd, covers quite a large area in the midst of the Five Towns and has been proudly known by the locals as "Shelton Bar" throughout living memory, due no doubt to its earlier (pre 1880) title of the Shelton Bar Iron Co.

"Shelton Bar" had its first steam loco as far back as 1856 and was consequently one of the first locations in North Staffordshire to use locomotives on the industrial scene. Over the years the works has operated some thirty steam locomotives - and possibly several others - with upwards of twenty at any one time. At its peak the rail system consisted of about 50 miles of track. Since 1953 the steam fleet has been gradually replaced by diesels, until there was only one steam loco still in use, and this (since 1969) in the capacity of spare engine only. A very varied and choice collection of locomotives has worked the system, ranging from a Beyer Peacock of 1856 vintage to products of the Lilleshall Iron Co, much modified and rebuilt four-coupled Barclays, a 1901 Dubs crane tank, large six‑coupled Hudswell Clarkes, and some home made variants. Fittingly, the last surviving steamer was locally built by Bagnall.

Our story begins in mid‑1940 when Shelton were shopping around for a new locomotive with quick delivery required due to pressure of war work. W. G. Bagnall Ltd of Stafford were able to offer one of their recently designed 15‑inch four-coupled saddle tanks with a delivery of only six months, so Shelton snapped up the offer and HAWARDEN* was subsequently delivered during November 1940.

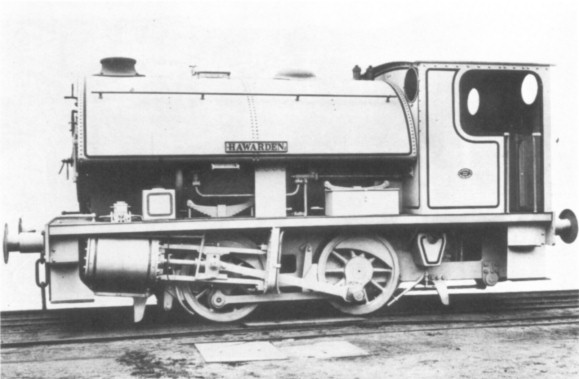

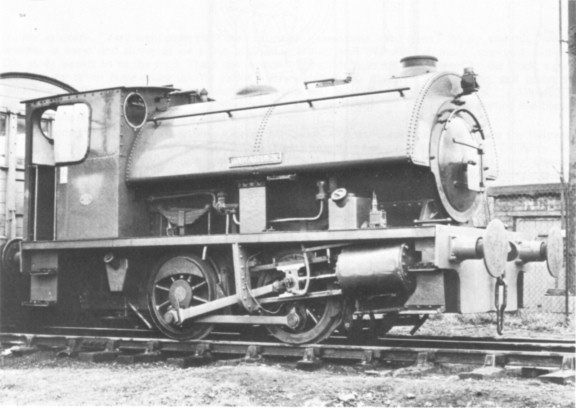

An official view of HAWARDEN (Bagnall 2623

of 1940) soon after completion.

(courtesy English Electric

Co Ltd)

HAWARDEN proved to be the last of a class of only seven. In late 1939 the Butterley Co Ltd had ordered the prototype, and two were built, one for Butterley and one for stock. Hence when Shelton placed their order on 10th June 1940, Bagnall's were able to offer them this stock loco (2623) on short delivery at a cost of £2950. She was named after the works of the then parent company, John Summers & Sons Ltd, Hawarden Bridge Steelworks, Shotton, Flints, but differed from her Butterley sister in that she was fitted with a steel firebox instead of a copper one, no doubt as a wartime economy measure.

HAWARDEN was used more or less continually during the war years and along with the remainder of the fleet had very little maintenance during this period; hence by the late 1940's she was very much run down. However, the repair shop at Shelton was already overcrowded with a back-log of work and as Bagnall's works at Stafford was not too far away it was decided to take an unprecedented step and send HAWARDEN there for overhaul, this being completed in 1948‑49. Further repairs were carried out at Shelton in 1952 when a copper firebox was fitted to replace the original steel one and thus bring her into line with the rest of the fleet.

She became a firm favourite, being much preferred to the Barclay locos, and in later years became the regular engine on the "Racecourse Job". This consisted of shunting the coking plant and coal stocking ground on the site of the Racecourse Colliery, situated parallel to the Cobridge Road. It was on this duty that she became a great favourite of mine, and I recall many a Saturday morning spent on her footplate. She had a regular crew on this job who took a great pride in her, more so when towards the end of 1964 she became the only steam loco on the works (apart from the crane tank) with a regular job. The remaining Barclays became spares and although one or more was always in use they moved round from one job to another as the diesels successively gave trouble!

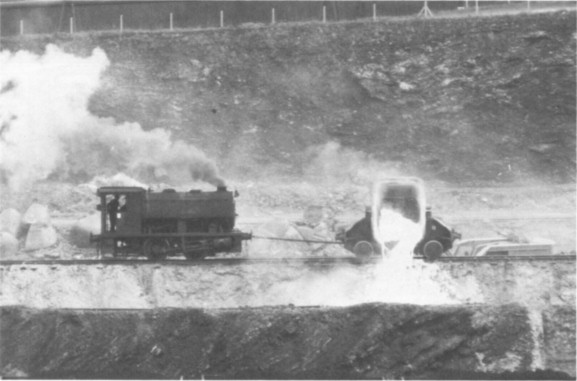

HAWARDEN on the Slag Run - the roughest and toughest locomotive

job at Shelton. 5th May 1969.

(A. C. Baker)

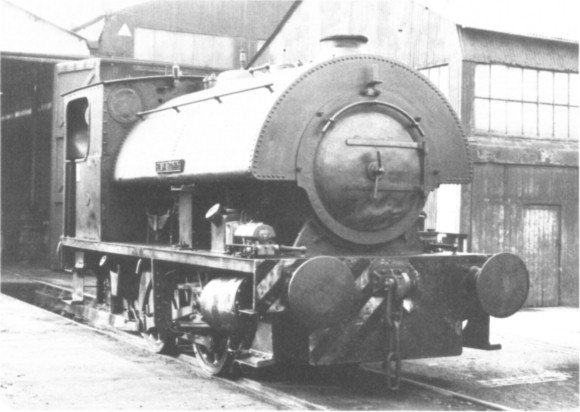

HAWARDEN outside the loco shed at Shelton in early 1972. Note on the running board the 5in gauge live steam model of her made by the author's father. (A. C. Baker)

By early 1966 HAWARDEN was again getting the worse for wear; in particular her tyres were now very thin and she was becoming very prone to derailment. Thoughts were voiced that she was to be scrapped and everyone - drivers, fitters (and myself) - were all very concerned. However, due to the continued unreliability of the diesel fleet it was decided to give her what was to be Shelton's last steam overhaul and new tyres were ordered. HOLMBURY, one of the remaining Barclays, was to deputize for her during the period of overhaul. In June the tyres arrived and HAWARDEN disappeared into the machine shop next door to the loco shed. Now when Shelton repair a loco they really go to town, stripping it to the bare frames and rebuilding it from scratch. HAWARDEN was no exception. I managed to call in most weekends and to see her gradually being assembled was indeed a sight for sore eyes. Every conceivable item was overhauled before assembly and she finally emerged resplendent in fresh green paint with red side rods and "wasp" striped buffer beams on 2nd October 1966, returning to her "own" job the following day.

She continued working the Racecourse until in early 1968 it was decided to close the coking plant at Shelton and do the coking for both Shelton and Hawarden Bridge at Shotton: an arrangement, it was said, that would reduce overheads. Actually it meant that coal from Wolstanton Colliery - on the opposite side of the ex‑North Staffordshire Railway to Shelton - would be taken by rail to Shotton, coked and then half of it returned to Shelton! The coal had previously been delivered to Shelton for coking on a conveyor over the main line.

Nevertheless, this meant that HAWARDEN was redundant as the Racecourse job no longer existed. Due to her recent overhaul she was then utilised as a spare engine in preference to the ageing Barclays, both of which were not used after September 1969. This left HAWARDEN as the only steamer in use, the Dubs crane tank having been taken out of service some time previously. From this time on she became a common user engine, deputizing for diesels whenever needed and her condition deteriorated accordingly.

Bad news came in 1969 when the inspector failed her boiler with broken stays. A second hand diesel had arrived only a few months before and we all thought the worst was unavoidable. We were, to our delight, proved wrong for on a visit in October 1969 1 found her in the shed at Shelton with the tank and cab removed. The boiler was lifted out of the frames and "the lads" were busy removing tubes and stays, though the repairs were to prove a long job for half way through the work they ran out of stay rod! The job was stopped and was not resumed even when the stay rod arrived. Time dragged on but in April 1970 there was a spate of diesel breakdowns and work started again. The stays and new tubes were fitted, but once more the diesel situation improved and work stopped. Diesel breakdowns caused repair work to restart in June, only to cease again a few days later! We began to wonder if it would ever be finished but finally the boiler was lowered into position, the cab and tank replaced and she was in steam again and working on 13th August 1970. No gentle running in: she went right in at the deep end on the "Slag Run", the roughest and most arduous job on the works. And so she continued to stand in for the various diesels for the remainder of 1970 and 1971, when there was a reorganisation of internal traffic which coincided with the closure of one of the mills. This reduced the loco work but HAWARDEN remained spare for the moment, seeing occasional sorties in the early months of 1972.

On Thursday 2nd March 1972 I am at work when my desk phone rings. I answer it to hear the voice of Ken Whitehead - the Shelton works photographer, and a keen railway enthusiast. He tells me that Shelton are expecting a second hand diesel from the BSC works at Irlam, Lancs, and HAWARDEN is for scrap. Bad news indeed so I must move fast. At home that evening I ring Allen Civil, my "Bagnall co‑partner enthusiast" who already owns J.T. DALY (Bagnall 2450) which is kept at Foxfield, near Cheadle. I ask him if he is interested in acquiring HAWARDEN . He is, so I phone Ken at Shelton the following morning and he arranges to have her disposal delayed, then makes arrangements for us to go and inspect her a week later.

So it was that we visited Shelton on Saturday 11th March 1972 - on what must have been one of the coldest mornings of the winter - to see an old and very much respected friend. She was pulled outside for examination and we were pleased to see that she was still in quite good condition. We say we would like to see her in steam. "Very well; come back next Saturday - same time, same place." We do, and this time the weather is warm and sunny as we arrive at Shelton armed with overalls and, more important, cameras. Our guide escorts us to the shed. There she is, standing outside with 100lb of steam on the clock, a good fire and the driver busy oiling up. We make a very detailed and thorough examination, and spend the remainder of the morning steaming round the works and generally enjoying ourselves. HAWARDEN performs very well and required little mechanical attention, though the side and connecting rod brasses need working on. She also requires a good clean and repaint.

Resplendent in a new coat of paint, HAWARDEN waits to take the first train of the day on the Foxfield Light Railway, 23rd April 1973. (A. C. Baker)

Drawing by Roger West from measured sketches taken from the locomotive in March 1973.

Next comes the business of settling a price, by "offer". To our surprise a letter arrives the following Wednesday to say our offer has been accepted. We all breath a sigh of relief, and select Thursday 30th March to move her by road to the Foxfield Light Railway Society's depot at Dilhorne, near Cheadle, some ten miles distant. Thursday turns out to be a day of continual rain and as HAWARDEN is pushed on to the low loader by one of the diesels - LEOPARD - we see another of the diesels being dragged to the shed after breaking down. So HAWARDEN leaves Shotton at 10.45 am for the last time and after attracting some attention as we pass through the centre of Hanley we arrive at Foxfield at 12 noon. The whole transaction has taken less than a month!

In conclusion, on behalf of Mr T.D.A. Civil and myself, I would like to express my gratitude to Mr D.H. Fields, the general manager at Shelton, and his staff - notably Messrs T. Coxon and K. Whitehead - for their help and consideration in the transactions that led up to the purchase of HAWARDEN for preservation.

* As a place name, Hawarden is pronounced "Harden"; but at Shelton the name of the locomotive was pronounced as it is spelt.

Summary of the Bagnall locos built to the same design as HAWARDEN.

|

Works Number |

Date Delivered |

Notes |

| 2590 | December 1937 | Supplied new to South Wales Coalite Co Ltd, Wern Tarw Colliery. Scrapped there May 1968. |

| 2606 | May 1939 | Supplied new to Royal Arsenal, Woolwich, HAIG. To Coltness Iron Co Ltd, Scotland, October 1957. Scrapped there September 1963. |

| 2607 | May 1939 | Supplied new to Butterley Co Ltd, Butterley Ironworks, Derbyshire, BUTTERLEY No.50. Later at Bailey Brook Colliery and scrapped there June 1964. |

| 2619 | September 1939 | Supplied new to Butterley Co Ltd, Ollerton Colliery, Notts, BUTTERLEY No.51. Later at Bailey Brook Colliery but returned to Ollerton Colliery and scrapped there in 1968. |

| 2620 | September 1940 | Supplied new to Imperial Chemical Industries Ltd, Middleton Works, Heysham, Lancs, number 1. Later owned by Trimpell Ltd. Scrapped September 1966. |

| 2622 | 1940 | Supplied new to Butterley Co Ltd, Bailey Brook Colliery, Derbys, BUTTERLEY No.52. To Ellis (Metals) Ltd, Spondon. Derbys, for scrap in March 1962. |

| 2623 | November 1940 | Supplied new to Shelton Iron, Steel & Coal Co Ltd, Etruria, Stoke-on-Trent, HAWARDEN . To Foxfield Light Railway Society, Dilhorne, 30th March 1972. (Property of Mr T.D.A. Civil.) |

Main Dimensions

| Cylinders | 15in by 22in | Working pressure | 180 lb/sq in | |

| Wheel diameter | 3ft 6½in | Weight in working order | 33 tons 10 cwt | |

| Fixed wheelbase | 5ft 6in | Tractive effort at 85% pressure | 17,820 lbs | |

| Water capacity | 920 galls | Overall length (frame) | 19ft 10½in | |

| Fuel capacity | 36 cu ft | Overall length (over buffers) | 23ft 6in | |

| Heating surface (tubes) | 560 sq ft | Overall width (over steps) | 8ft 2in | |

| Heating surface (firebox) | 54 sq ft | Overall height ** | 10ft 7½in | |

| Grate area | 10 sq ft |

NOTES ** This applies to 2622 and 2623 only: the other five members of the class were slightly higher than this and had normal capped chimneys instead of the "austerity" type.

All (except 2623) had copper fireboxes and steel tubes when new. In addition 2623 was fitted with two mechanical lubricators to feed the cylinders, axle boxes and slide bars. 2590 had less tubes and the tube heating surface was only 550 sq ft.

"Light Railway Construction.

– While hundreds of miles of light or feeder railways are being annually constructed in nearly every European country, our beautiful Light Railways Act of 1896, as interpreted by the Board of Trade, to suit the fads and fancies of Local Authorities, has brought light railway construction in this country practically to a standstill and the Light Railway Commissioners, in their 12th Annual Report,think it desirable to again draw attention to the need for the construction of light railways which has been found to exist in many parts of the country, and to express the opinion that such a need is unlikely to be met unless and until some of the amendments of the Act are effected.

In other words, under the absurd conditions imposed by the Act, no one will put up the money to construct this much-needed means of communication. Just now the British investor is not exactly keen to embark his capital on any home enterprise or industry, and least of all those which are likely to be blackmailed in their infancy and fleeced during their life by local Authorities. And until the favourite dog-in-the-manger attitude of Local Authorities is controlled light railways are not likely to be built. The May applications to the L.R. Commissioners reach the total of 10, but they are mostly for renewals and extension of time. One is for powers to work the derelict Mawddwy R. as a light railway, and there is an application to construct a steam line of normal gauge, 8¼ miles long, in South Anglesey."

("The Railway Engineer," July 1909. This magazine was a frequent critic of the working of the Act and suggested various reforms. Applications to the LRC were made only in May and November. The line in South Anglesey was not built. — KPP)