| THE INDUSTRIAL RAILWAY RECORD |

© JUNE 1975 |

STEELWORKS BALDWINS

RODNEY WEAVER

Three quite different Baldwin 0‑4‑0 saddle tanks are the subject of this short article, their common feature being that they were built in 1928‑30 for major steelworks in the USA. Examination of their differences shows just how much variety can be worked into such a basic type of industrial locomotive by a builder noted for mass production of standardised designs.

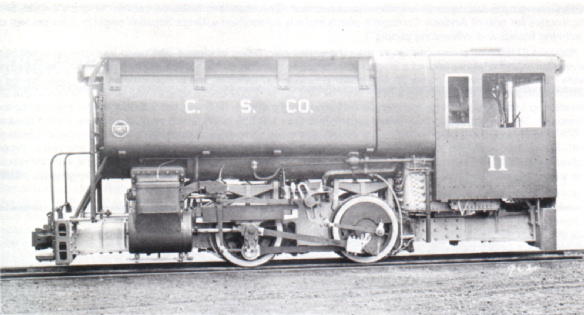

Standard gauge Baldwin 58366 was ordered by the International Harvester Company for the Wisconsin Steel Company. A typical Baldwin industrial locomotive of deceptive dimensions it was almost identical in size to a GWR 5700 class pannier tank, which would be considered a large industrial locomotive in Britain. (courtesy H.L. Broadbelt)

Baldwin 58366 was a good example of a small American standard gauge industrial locomotive, being a class 4‑28‑C with 17in x 24in cylinders, 4ft 2in driving wheels and 180 lb/sq in pressure. The boiler had a total heating surface of 1146 sq. ft and a grate area of 15.9 sq ft, being oil fired. Carrying 1250 US gallons of water and 375 US gallons of oil, the locomotive weighed 104,340 lb (46 tons 11 cwt) in working order. It was of quite orthodox construction with bar frames, Stephenson's valve gear and slide valves and, like most American standard gauge locomotives, was equipped with air brakes and electric lighting.

2ft 6in gauge Baldwin 58677, built for the Edgar Thompson Steel Works of the Carnegie Steel Company, was unusual (for an American locomotive) in having plate frames. (courtesy H.L. Broadbelt)

Baldwin 58677 was also of class 4‑28‑C, but there the similarity with 58366 ends for it was a very modern 2ft 6in gauge locomotive with 17in x 20in cylinders, 3ft 4in driving wheels and 180 lb/sq in working pressure. The boiler was slightly shorter with a wider firebox, having a heating surface of 949 sq ft and a grate area of 18.9 sq ft. It too was oil fired, the oil being carried in a tank over the firebox instead of in the bunker. The water capacity was 1300 US gallons and oil 100 US gallons, and the weight in working order 101,800 lb (45 tons 9 cwt). The construction of this locomotive is most interesting as it was a rare example of a plate-framed Baldwin locomotive, although the frame plates only extended from the rear of the split cylinder block to below the firebox, the outer ends of the chassis being formed by cast dragboxes to which were bolted a hollow cast front buffer beam and a more traditional wooden rear buffer beam. The locomotive had balanced slide valves driven by Walschaerts valve gear which featured a valve crosshead cantilevered out from the valve chest but with the radius rod suspended by a link in the usual manner. One wonders whether the use of plate frames in a locomotive for one of Andrew Carnegie's plants had any connection with his Scottish origin and his precept of "winning friends and influencing people"!

3ft 0in gauge Baldwin 61189, built for the Cambria Plant of the Bethlehem Steel Company, can be compared with the largest standard gauge 0‑6‑0's used on European industrial lines. (courtesy H.L. Broadbelt)

Baldwin 61189 was somewhat larger than the earlier pair, being of class 4‑32‑C, and its dimensions will be a revelation to those whose idea of a 3ft gauge locomotive is an Isle of Man Railway 2‑4‑0 side tank. The cylinders were 19in x 22in, driving wheels 3ft 6in, boiler pressure 190 lb/sq in, the boiler, coal fired this time, having a heating surface of 1459 sq ft and a grate area of 19.7 sq ft. 2,000 US gallons of water were carried in the all-enveloping saddle tank but no room could be found for the coal, which was carried on a tender supplied by the customer. The weight of this locomotive was no less than 130,535 lb (58 tons 5 cwt), almost exactly the same as a GWR 1500 class 0‑6‑0 pannier tank. The design was more conventional than that of the Carnegie locomotive, with bar frames extended front and rear by a form of cast plate frame - possibly cast in one piece. Piston valves were fitted, driven by Walschaerts gear which this time had the valve crosshead integral with the rear of the valve chest and the radius rod extended through the expansion link to a lifting arm on the weighshaft.

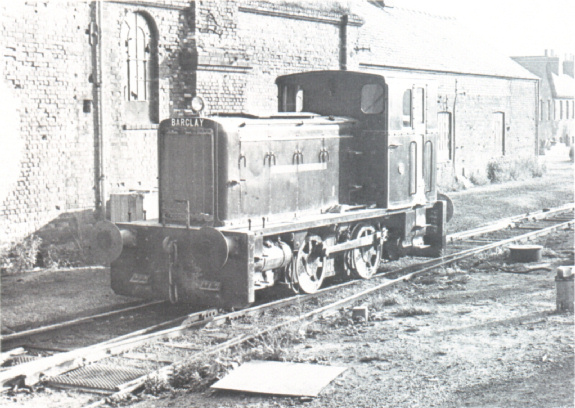

1974 Aidan Fuller Memorial Trophy Photographic Competition Entry. Early morning at the granite quarry of Bardon Hill Quarries (Ellis & Everard) Ltd, Coalville, Leicestershire, on 29th July 1972. 0‑4‑0 diesel mechanical Andrew Barclay 400 of 1956. (H. Collier)

'The Derby Kilburn Colliery Company, Limited, has increased its capital to the extent of £20,000. At present the coal has to be conveyed by road to Derby, but the company intends to lay down a tramway to carry the coal to a point near the Derby racecourse, by which means it is estimated that a saving of 1s. 10d. per ton will be effected.' (From "Industries & Iron," issue dated 30th June 1893. - KPP)