| THE INDUSTRIAL RAILWAY RECORD |

© DECEMBER 1967 |

BAGNALL ARTICULATED LOCOMOTIVES

ALLAN C BAKER

When speaking of Bagnall articulated locomotives most people will think of MONARCH, now happily preserved for posterity on the Welshpool & Llanfair Light Railway, but this is only one of a class of seven to emerge from the Stafford works. These locomotives, however, are not the only Bagnall articulated machines, being preceded by some years by five double bogie articulated diesels (of which more later). The reason for the development of the articulated steam locomotive was to double the power output whilst keeping the locomotive sufficiently compact and flexible to negotiate the very sharp curves and severe gradients to be found on the narrow gauge sugar plantation lines in South Africa. One of the disadvantages of the articulated locomotive is the need for flexible steam and exhaust pipe joints. As Robert Fairlie overcame this in 1865 I suppose Bagnall’s thought they would have little difficulty in 1936! They did, in fact, incorporate a proprietary article, namely, the "Flextel" patent joint, also made in Stafford by the then well known firm of Dorman & Co Ltd. There is no doubt that with proper maintenance these joints should give very little trouble.

The first of the design to be built, an 0−4−0 + 0−4−0 side tank on 2ft 0½ in gauge, was Bagnall 2544, ordered by A & H Macnay Ltd., agents; it was delivered F.O.B. (free on board) at Liverpool on 4th September 1936 for Illovo Sugar Estates, Illovo, Natal, South Africa. The boiler, cab, fuel space and water tank were mounted on a main frame built up from "H" section girders, the whole being carried on two identical four wheel bogies with outside frames and 7½in by 12in cylinders. The connecting rods drove on fly cranks, and the Walschaerts valve gear was so arranged that when the rear bogie was in full forward gear the other was in full back gear, both sets of valve gear being operated by a common reversing lever. This arrangement was made necessary by the fact that the cylinders were set back to back (or front to front, depending on the way one looked at it!). The above description, except for cylinder size and gauge, is typical of all the class.

These Bagnall locomotives have been described by various writers as Garratts, Fairlies, Malletts and Meyers, but strictly speaking they are a design on their own, bearing some resemblance to the Garratt in that the boiler, cab, water tank and coal bunker are mounted on a common frame which is carried on the two power bogies. It will be noticed that the Bagnall engine is more compact and that the bogies are under the boiler. This form of construction posed a problem, however, for with the rear power bogies being directly under the firebox a normal locomotive type boiler was out of the question. The designers overcame this by using an enlarged version of their "Bull Head" boiler.* This marine type boiler was a favourite of Bagnall’s, being used by them from about 1890 up to the time production ceased. In fact it was fitted to the last narrow gauge steam locomotive to leave the Stafford works.

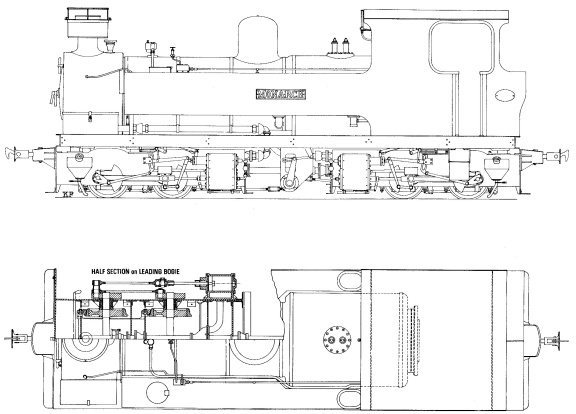

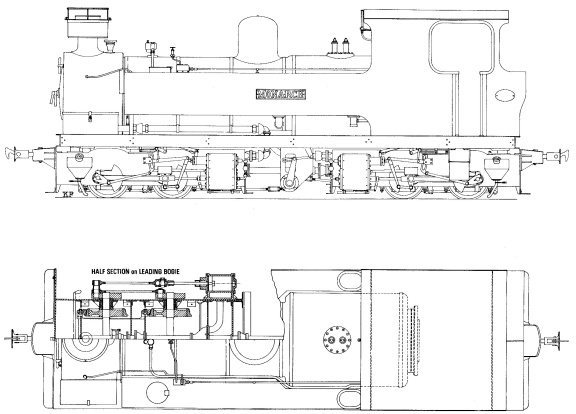

This drawing is based on Bagnall drawing 19347, which is a 'Proposed Design of new Diesel Locomotive' but features shown in the photograph but not in the drawing have been incorporated. The drawing of the steam loco is a copy of Bagnall drawing No.33162/28A, being a general arrangement of loco 3024 as supplied to Bowater Lloyds.

The next articulated locomotive to be built was, in fact, Bagnall’s next engine, their no.2545; actually it was built alongside 2544 and delivered before it F.O.B. Liverpool on 21st May 1936. Named RENISHAW No.5 and costing about £2,500, this engine was also ordered by A. & H. Macnay Ltd, for delivery to Crookes Brothers Ltd., Renishaw Sugar Estate, Natal, South Africa. She was larger than 2544, the main difference being the increase in cylinder size to 9in by 12in, and set the pattern for future engines of the class.

No more of the class were built until 1946 when Macnay’s ordered two (Bagnall nos.2830 and 2831) for Sir John L. Hullett & Sons Ltd., for use at the Darnall and Felixton sugar estates in Natal. Named TUGELA and NONTI respectively, both engines were on 2ft 0½in gauge, and were identical to no.2545 as were the next two, nos.3014 and 3015. These were built in 1953, also for Sir John L. Hullett & Sons Ltd. and were named MBOZOMA and SINKWAZI, the nameplates being added after delivery.

The next engine of the class – no.3024 MONARCH, also built in 1953 – was the last. This 2ft 6in gauge engine was built for the Sittingbourne works, Kent, of Bowaters Lloyd Pulp & Paper Mills Ltd. – very old and valued customers of Bagnall’s. The only difference, apart from the gauge, was the increased boiler pressure of 185lbs. per sq. in.

In 1954 Bagnall’s carried out a survey, under actual working conditions, of all their locomotives operating in South Africa. The resulting report exposed the appalling conditions under which steam locomotives were required to work and it is obvious that the articulated design was not a success. For instance; at Illova it was found that 2544 was completely out of favour and after twelve years’ service was abandoned owing to high maintenance costs, proneness to priming, and being of insufficient power. The boiler was worn out and the owners would not spend money on either a new boiler or on repairs to the existing one. The engine has since been scrapped.

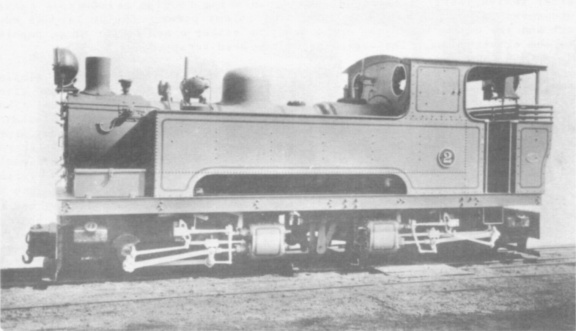

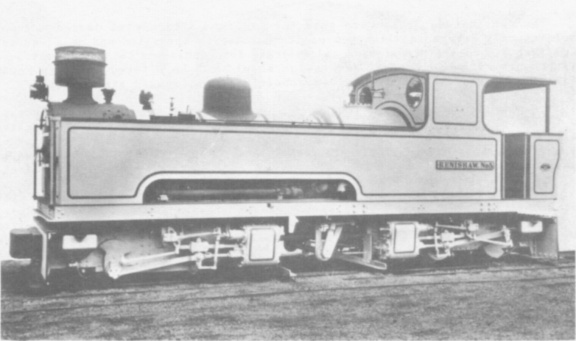

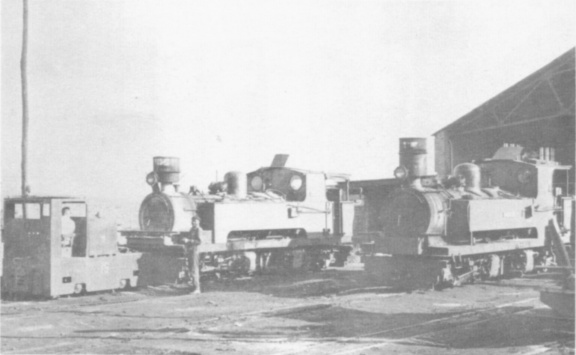

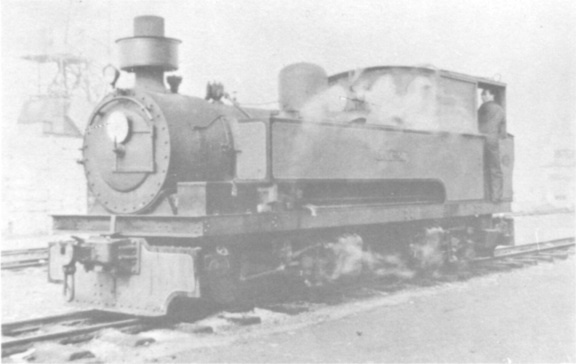

The first two steamers at Stafford prior to shipment to South Africa.

Upper photograph is of Bagnall 2544, the lower being Bagnall 2545.

From Hullett’s, Darnall, where 2830, 2831 and 3015 were working, similar complaints were received; they were difficult to maintain, the tubes had given a lot of trouble and had welded in, and the "bull head" boilers were not liked anyway. Much trouble had been experienced with the flexible steam and exhaust pipe joints, no doubt caused by the brake cross beam striking the exhaust pipe. At Felixton everything was found to be wrong with 3014 according to the charge hand fitter! But some of the complaints were similar to those made at Darnall so all cannot be blamed on bad maintenance, which left a lot to be desired. The tubes had given trouble (probably due to over-expanding) and had had to be beaded and welded. The steam and exhaust pipes had broken continuously, and it was said that the engine took sixteen hours to raise steam! At Darnall, where a compressed air blower was used, the steaming time was given as from six to eight hours.

Finally, the only place which had a good word to say was the Renishaw estate where 2545 was at work. Here the Chief Engineer was generally satisfied with the engine, although he had had considerable trouble with the steam and exhaust pipes cracking and had replaced all of them. In direct contrast the "bull head" boiler was liked as it had given very little trouble, although some cracks had developed in the throatplate. An interesting side issue here was that it was standard practice to build up worn tyres by welding and they complained that Bagnall tyres were not so "weldable" as Hunslet’s!

The conclusions drawn were that the standard articulated design was not sufficiently robust to withstand constant abuse in operation and maintenance, and that it was too complicated and delicate for conditions on the plantations. The report recommended that the design should not be offered again in South Africa and that manufacture should concentrate on "rugged simplicity".

It will be realised that the articulated design was not a great success, a fact borne out by Bowaters’ readiness to dispose of MONARCH which was, after all, their newest engine. However, it is interesting to note that in spite of all their criticisms, Hullett’s ordered 3014 and 3015 in 1953 after seven years’ experience with 2830 and 2831, and as far as I know they are still in use!

MONARCH worked reasonably successfully at Bowaters but, in common with others of the class, was very slow in raising steam and heavy on maintenance; I believe it was little used towards the end. Early in 1966 MONARCH was acquired by a member of the Welshpool & Llanfair Railway Preservation Society (who wishes to remain anonymous). Before leaving Sittingbourne for Llanfair MONARCH was overhauled and repainted in Bowaters’ standard livery of green edged with black and red lining.

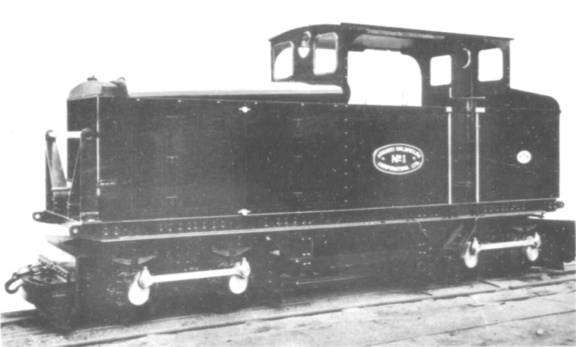

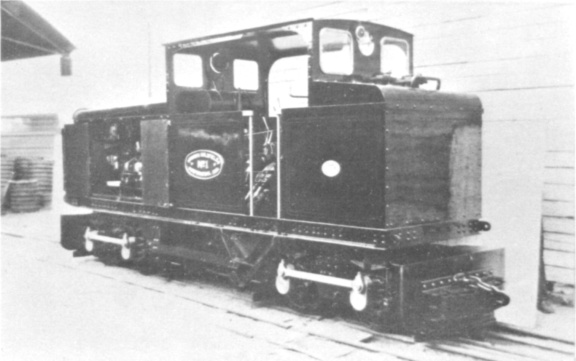

The articulated diesel locomotives mentioned earlier were of a very novel design being the creation of Bagnall’s senior draughtsman at the time, Mr I. ‘A’ C. Farr, who had come to them from the Great Western Railway. The first engine, on two four wheel bogies, was ordered in January 1933 by the Ashanti Goldfields Corporation Ltd., for their 2ft 0in gauge system in West Africa. It was required to haul up to 200 tons on a line having a maximum grade of 1 in 25 and curves of up to 60ft radius. The locomotive, Bagnall 2494, was delivered F.O.B. Liverpool on 14th June 1933 at a cost of £1,950.

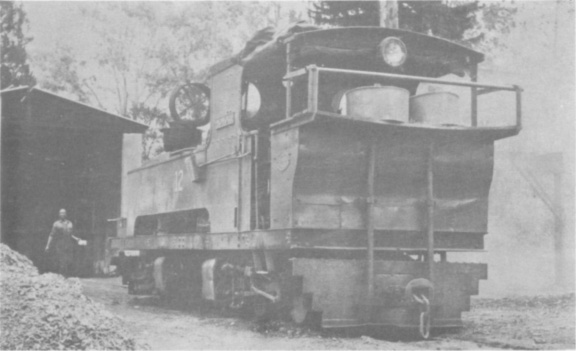

Two views of Ashanti Goldfields No.1, Bagnall 2494 of 1933.

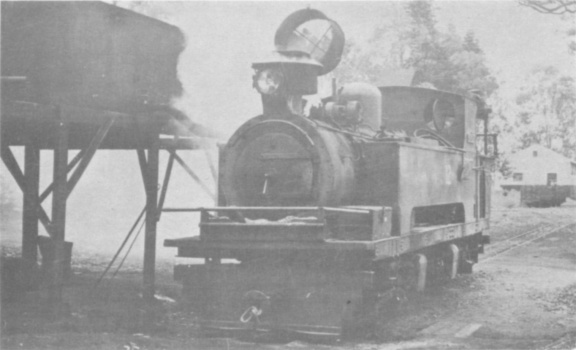

Scenes on two of the systems operated by Hullett's in South Africa.

Upper: Bagnall 3014 UMHLATUZI shunting at Felixton in July 1963.

Lower: Darnall shed, with NONOTI from Kearnsey and UMHLATUZI from Felixton

(Frank Jux)

Two views of Bagnall 2831, NONOTI, at the Kearnsey shed of Hulett's Sugar Corporation Ltd. (Frank Jux)

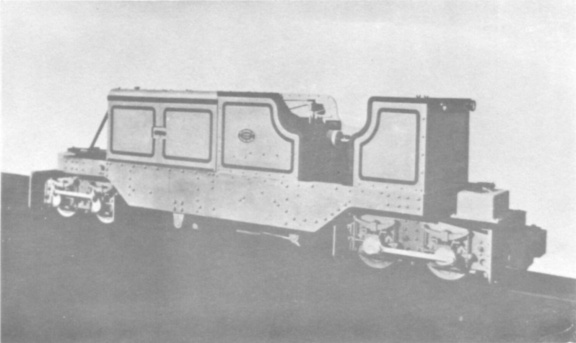

Bagnall 2498 of 1934 as built for underground service in Flintshire.

Last of the line - MONARCH (Bagnall 3024 of 1953) at Bowaters.

Note modified spark arrester as latterly fitted.

Powered by a Gardner 6 cylinder diesel engine typical of their design even to this day, the power output was 57 bhp at 1000 rpm, 62½ bhp at 1100 rpm, and 73 bhp at 1300 rpm. On test at full load the fuel consumption was 38lbs per bhp hour. The engine drove through a Vulcan-Sinclair fluid flywheel to a two-speed pump lubricated epicyclic gearbox combined with a dog clutch reverse gearbox. This arrangement was designed and built by Bagnall. The drive was via a universally jointed propeller shaft to "Moss" gear worm drives on the first and fourth axles, the other two axles being driven by coupling rods. In low gear at an overall reduction of 22.4 to 1 a speed of 3½ to 4mph was obtained, and in high gear at 8 to 1 reduction 10 to 12mph. The tractive effort available at the rail based on 75 per cent power output was 5,350lbs at 3½mph and 1,900lbs at 10mph. The whole arrangement was quite foolproof to enable it to be driven by unskilled natives

The next locomotive to follow this design was much smaller but embodied the same principles. No.2498, built in 1934 on 1ft 10½in gauge for the Halkyn Distyrict United Mines Ltd., Bryn Owel, Flintshire, was delivered on 23rd March 1934. It was powered by a Deutz diesel engine of 22 to 24bhp at 700rpm, with the drive, as before, through two-speed epicyclic gearbox. It weighed 6½ tons and cost £1,300. At Halkyn it was used to haul trains of up to 100 cars, each weighing 26/30cwts, at 10mph over the two mile long underground main line. The success of 2494 prompted the Ashanti Corporation to order another locomotive, ASHANTI No.2, in January 1934. On this machine the driving wheels were increased in diameter from 1ft 8in to 2ft 0in and a differential gear was included in the drive as it was found that 2494 had suffered with binding on the curves. A new gearbox with differential was also ordered for 2494 to bring it into line with its new sister, 2514, which was delivered F.O.B. Liverpool on 10th October 1934, at a cost of £1,950 (the same as for 2494).

The next two of this design (the last) were both for the Ashanti Corporation and were identical to their No.1 except for the inclusion of the differential and the cost (£1,990). ASHANTI No.3 (Bagnall no.2546) was delivered on 10th August 1936 and ASHANTI No.4 (Bagnall no.2568) followed early in 1937.

It is, I think, a great pity that during the Second World War Bagnall’s were more or less forced to cease diesel locomotive construction and concentrate on the steam engine. This must have been a bitter pill to swallow as they were pioneers in the internal combustion locomotive field, their first being built in 1911! It is my opinion that, had it not been for the conditions forced upon them by the War, their double bogie design would have become very popular, as the few examples built gave excellent trouble-free service. Although the engine at Halkyn had a short life and was scrapped about 1937, the Ashanti engines as far as I know are still working.

In conclusion I would like to thank Messrs. W.A. Smith, I. ‘A’ C. Farr and T.A. Civil for help and information, member Ken Fleming for his excellent drawings and The English Electric Company Ltd. for permission to use the official photographs.

* The great disadvantage of these boilers was the time taken to make steam, but once pressure was obtained they would steam very well provided the crew appreciated their requirements and fired them to their liking.

DIMENSIONS

| Locomotive Nos. | 2544 | 2545† | 3024 |

| Cylinder bore | 7½in | 9in | 9in |

| Cylinder stroke | 12in | 12in | 12in |

| Wheel diameter | 2ft 0in | 2ft 0in | 2ft 0in |

| Bogie wheelbase | 3ft 3in | 3ft 3in | 3ft 3in |

| Total wheelbase | 16ft 3in | 18ft 3in | 18ft 3in |

| Track gauge | 2ft 0½in | 2ft 0½in | 2ft 6in |

| Working pressure | 180 lbs/sq in | 180 lbs/sq in | 185 lbs/sq in |

| Fuel capacity | 50 cu ft | 40 cu ft | 40 cu ft |

| Water capacity | 500 gallons | 500 gallons | 500 gallons |

| Heating surface: | |||

| Boiler tubes | 300 sq ft | 395½ sq ft | 395½ sq ft |

| Firebox | 33 sq ft | 36 sq ft | 36 sq ft |

| Superheater | 60 sq ft | 70 sq ft | 70 sq ft |

| Total | 393 sq ft | 501½ sq ft | 501½ sq ft |

| Grate Area | 9 sq ft | 11½ sq ft | 11½ sq ft |

| Tractive effort* | 8,600 lbs | 12,400 lbs | 12,737 lbs |

| Boiler feed |

All locomotives – two 6mm injectors |

||

| Weight (working order) | 23 tons (approx) | 28½ tons | 28½ tons |

† Also 2830, 2831, 3014 and 3015.

* Calculated at 85% of boiler working pressure.