| THE INDUSTRIAL RAILWAY RECORD |

© AUGUST 1973 |

THE BRITANNIA FOUNDRY , PORTMADOC

C.G. DOWN

In 1971, by the fortunate - but rare - coincidence of being in the right place at the right time, I was able to save a substantial proportion of the records of the Britannia Foundry, Portmadoc, from being consigned to a bonfire. Unfortunately I was too late to salvage the order books, but the carload of paper that was eventually saved - including drawings, notebooks and correspondence - forms the basis of these notes.

Nineteenth century North Wales had a large number of foundries serving the slate and stone quarries in the area. In Caernarvon were DeWinton and H. Owen & Son, while the shipping quays of Port Dinorwic and Port Penrhyn each had their foundry. In the heart of the Blaenau Ffestiniog quarrying area was the foundry of J. Dunnell Garrett & Co Ltd, with William Lewis' Festiniog Foundry at nearby Tanygrisiau.

Portmadoc had at least three competing foundries. Britannia, the subject of this article, will be covered in detail below. Nearby was (and is) the Glaslyn Foundry, while Owen, Isaac & Owen traded from the Union Iron Works (founded by 1869). Union was at some time owned by Griffith Owen, while another firm ("Isaac, Portmadoc") was perhaps also connected with Union.

DeWinton, of course, is well known as a locomotive builder. It is probably less generally realised that other firms were also intimately involved with railway work. Not, perhaps, a great deal of locomotive work but rails, wagons, turntables and incline drums formed a large part of each business, the remainder of the trade being in slate saw tables and dressing machines, and general iron founding and fabricating. The object of this article is, therefore, to examine in more detail the railway activities of one of these small foundries.

Fig 1 The Britannia Foundry (not to scale)

History

The Britannia Foundry was established beside the turnpike road over the Cob at Portmadoc, opposite the Festiniog Railway's Harbour Station. A rough note made about 1926 suggests that the business was started in 1851, and grew rapidly with the prosperity of the region. Verbal information in 1971 gave 1845‑50 as the starting date. The earliest mention of the owner is June 1868, when Robert Williams was operating the business. At some period between December 1869 and November 1873, the firm became J.H. Williams & Sons, a style which lasted at least to 1882. Later Robert Williams (perhaps the grandson of the founder) became the owner.

At some time prior to 1927, the foundry was purchased from Robert Williams by E.R. Owen, trading as "E.R. Owen, Britannia Foundry". By 1936 the precedence had been changed to "The Britannia Foundry. Proprietor E.R. Owen". Owen worked the foundry for the rest of its independent existence.

E.R. Owen may well have been the "& Son" in H. Owen & Son, Caernarvon. In 1930 numerous orders were subcontracted from Caernarvon to Britannia while, by 1933, the Caernarvon works had closed and all its patterns were taken over by Britannia.

The late 1920's saw considerable changes in Portmadoc. Union Iron Works had closed about 1914, and now Glaslyn was in trouble. In 1928 Britannia was fulfilling some of their orders and supplying castings, coke and fabrications. Glaslyn had traded as Chas. Williams & Sons up to about 1928 when the Glaslyn Foundry & Engineering Co Ltd took over, Charles Williams becoming one of the four directors. A.J. Dodd, another director, attributed Glaslyn's financial difficulties to price-cutting due to competition with Britannia. One reason for Glaslyn's difficulties may have been their attempt to move into new markets; in 1929 they described themselves as makers of colliery plant, surely an unpromising line of business to carry on from Portmadoc.

Britannia was not free from difficulties either, and unofficial talks were held with Glaslyn to explore the possibilities of a merger. The opportunity came in 1930. Glaslyn, having virtually eliminated the Williams' interests, went into liquidation in February, and Owen considered making a bid for the firm as a going concern. Glaslyn's total capital was then £6,000 and the fact that Owen contemplated purchasing the £1,000 of ordinary shares for only 6d (2½p) each suggests that Glaslyn was in a very poor state. No merger occurred, however, and the two foundries remained separate.

The Williams' interests apparently made a comeback for the new company formed to operate Glaslyn was Charles H. Williams Ltd. Apart from having ceased foundry work to concentrate on machining and fabricating, this company still operates Glaslyn. It is of interest that the gatepost at Glaslyn bears the name of J.H. Williams & Sons of Britannia Foundry.

Britannia continued to trade until about 1958 when Owen gave up the business. The only major change was the erection of a large new steel-framed extension, probably to accommodate war work. About 1958 the business was taken over by a firm from Wrexham (?) who used Britannia as an overspill for their main factory, and employed two men until mid‑1972. After being offered for sale for some years, the site has been purchased for redevelopment in the form of holiday houses such as were recently erected near the Festiniog Railway Station. Demolition of the foundry began about November 1972.

General Business

The foundry's stock‑in-trade in the early days was slate working machinery for which it gained a good reputation. The only trouble with such machinery was that it lasted too well: in the 1890's after the end of the speculative era of slate quarrying, a flood of second-hand machines came on the market, and thereafter Britannia undertook mainly repairs and renewals for North Wales. New equipment was, however, built for the South Wales and Lancashire slate trade, and for export to Ireland, Canada and South Africa in the 1920's. So far as can be determined, Britannia supplied goods to every slate quarry operating in England and Wales at this period, with the exception of Penrhyn, although the Dinorwic business did not amount to much.

Although Britannia has been implicated in the shipping trade of Portmadoc, surviving records indicate only a very slight involvement. Just two drawings survive: the first of a winch for an unspecified slipway; and the second of ironwork for a mast. The supply of ironwork for ship repairs was probably a part of the business which fell away very rapidly after about 1880.

|

Fig 2 The Britannia Foundry in 1936 |

|||

| 1 | Machine Shop | 4a | Sand and Coke Shed |

| 1a | Office | 5 | Joiners Shop |

| 1b | Stores | 5a | Sheet Stores |

| 2 | Fitting Shop and Garage | 6 | Steel Warehouse |

| 2a | Stores | 6a, b | Iron Warehouse |

| 2b | Lighting Power House | 6c | (not shown)

Tube Warehouse above 6 |

| 2c | Core Oven (practically useless) | ||

| 3 | Moulding Shop | 7 | Joiners Shop |

| 3a | Fettling Shop | 7a | Shed and Store |

| 4 | Smithy | 8 | Old Boiler House |

Apart from railway work, which will be mentioned below, the foundry went into virtually every branch of iron working and also employed two carpenters who were often so short of work that Owen had to plead with customers to include some wood in their order. Glass was occasionally supplied, and sometimes the firm acted purely as contractors. One such case was the Pwllheli Granite Co Ltd who in 1929 were contemplating shipping stone from Portmadoc. Owen suggested tarring Oakeley No.1 wharf to make a lorry road and to provide somewhere to dump the granite. There were lots of tramlines and turntables which he thought could be used to reload the stone into wagons for tipping into the ships. Another instance was the installation of central heating in the local post office.

It is noteworthy that whereas most orders involved little more than a letter or a scribbled postcard, anything concerning the Government required the whole rigmarole of tenders and interminable forms and letters. While very few records of complaints exist as to the quality of goods supplied, more are on record for those cases where Owen also undertook the erection on site. Finally, although numerous orders and enquiries were written in Welsh, Owen's replies were almost invariably in English, going only so far as to put the Welsh equivalent of "Yours sincerely".

One line which became a staple part of the business was road furnishings. Drains and manhole covers were supplied in large numbers, as were signposts. Most of the main roads in Caernarvonshire - particularly the A5 - have some of Owen's signs.

In short, nothing was too big or too small to be considered. Although the entire business was in 1936 valued at only £2,880 (buildings, fixtures and stock), the largest successful tender known was some £4,000 for re‑equipping the Nantmawr Quarry of the Chirk Castle Lime & Stone Co Ltd in 1930. The second largest was the construction of the top mill at Llechwedd slate mines at Blaenau Ffestiniog, for which £2,000 was tendered. At the other end of the scale came jobs such as re‑tinning a fish kettle. My own favourite of the non‑railway work is the New Britannia Bracken Cutter, a charming type of mowing machine with Heath Robinson characteristics, of which only one is recorded as being sold.

Railway Business

Britannia Foundry's railway activities must be seen in the context of the local railway scene. On the one hand there were the slate quarries operating on the nominally 2ft gauge; on the other, the stone quarries at Penmaenmawr, Lleyn and elsewhere tended towards 3ft 0in gauge. Each industry had its preferred styles of wagon. The stone quarries required heavy wooden tipping wagons, while the slate quarries had their own designs of slab, rubbish and finished slate wagons. It follows therefore that many of the designs tended to be, at most, the foundry's interpretation of the standard quarrying designs, varying only in detail from those built by other foundries. In most cases the customer simply ordered "wagons" or "wheels" in the sure knowledge that Owen would produce what was required without any specification.

Secondhand equipment formed a fair part of the business in the 1920's and 1930's, as did the purchase of scrap. In the case of wagon wheels, a standard exchange rate operated in the quarries: for every three old wheels sent to the foundry, Owen would supply one new wheel free. The demand for new wheels was considerable, even in the depressed inter-war years. Records exist of orders for 278 wheels in 1934‑36, and no doubt this figure does not tell the whole story.

Casting work, of which wheels and pedestal bushes formed a major part, was normally done only on one day a week, and orders were usually accommodated during the rest of the week. Likewise, Owen sometimes tried to encourage an order by saying that he was casting in a day or two and could thus promise rapid delivery. Standard designs of wagons were often made for stock, since a promise of prompt delivery might swing an order away from Glaslyn. It was common practice for a customer to approach both Glaslyn and Britannia, and sometimes the foundries each undertook half an order. This tended to involve each foundry completing its part of the work at the same time in order to load into the same railway wagon. Curiously, such co‑ordination between adjacent foundries was achieved by letter, suggesting that relations were not always of the best.

Scrap rails were another part of the business. In 1936 Owen loaded 87 tons of scrap from Croesor: six tons of rail in the shipment (from the Pantmawr incline of the Croesor Tramway) were purchased by Maenofferen slate quarry in September, while in July 2½ tons had been booked to Llechwedd Quarry's account. The Pwllheli Granite Co Ltd at Minfordd was quoted for 2 tons of new 20lb bridge rail in January 1935, while in June 1933 Criccieth Urban District Council was quoted for flat bottom rails.

Most of the orders are routine, but some oddments occur. Why, for example, did Mr C. Osborne of the Toll Gate, Railway Bridge, Dolgelley, order rail dog spikes in September 1936? Another is the request from the Dorset Quarry Co Ltd for three 2ft 0in gauge turntables delivered to Swanage. Owen's tender of £32 was not accepted. Certain orders - though not that one - from outside North Wales are explicable because of the slate quarry connection: for example, the Bendruff, Froe & Madranna Quarries Co Ltd of Leap in County Cork, a slate quarrying firm established in 1832, asked in December 1934 for a quote for 2ft 0in gauge turntables to replace some damaged ones. But what was the connection which prompted, on 15th May 1928, agents Harris, Scarfe Ltd of London to order 36 railroad wrenches "as per W & B Railroad Special" for delivery to Australia?

Another novelty, which raises interesting questions, was the order on 31st March 1933 from the Chirk Castle Lime & Stone Co Ltd for delivery to Nantmawr Quarry, Oswestry, of twenty-four 2½in wagon axles and twenty-four 3in wagon axles, "since each wagon has one axle of each size". One wonders what sort of wagons these were.

In October 1934 the Merioneth Mining Co Ltd, which was reopening the Prince Edward gold mine at Trawsfynydd in conjunction with the Kingsland Property Co Ltd, forwarded a V‑skip to Britannia. It was too wide for the mine, and was to be reduced to 2ft 6in width. This company was an impoverished concern which did everything by halves: in September 1934 they had asked for a quote for 72 rail dog spikes!

Locomotive Work

The supply of materials for the repair of quarry locomotives formed only a minor part of the business, but several scattered references exist. One of the more interesting occurred during the re‑equipping of Nantmawr Quarry referred to above. The quarry forwarded to Owen in February 1930 a list of plant for sale at Bartley Reservoir, Birmingham, by Thos. W. Ward Ltd of Sheffield. Item 13 comprised:

"Two "Muir Hill" 2‑ft GAUGE PETROL LOCOMOTIVES, each having a 4‑cylinder "Fordson" engine; two‑speed gearbox, forward and reverse; radiator; brake to all four wheels; sanding gear."

Unfortunately, Owen did not advise that these be purchased. *

Firebars were frequently supplied, the Penmaenmawr & Welsh Granite Co Ltd being the largest customer. Between November 1929 and March 1930 Britannia, under sub-contract from H. Owen & Son, Caernarvon, supplied Penmaenmawr with no less than 242 firebars for quarry locomotives. 50 were for HUGHIE and TIGER, 36 for PENMON and PUFFIN, 14 for LLANFAIR,, and 142 (to 23 different patterns) were unspecified. For Penmaenmawr's Trevor Quarry, Owen quoted direct for 42 firebars for BETTY, and 48 for MARK, in June 1928.

Other oddments include a quote on 18th March 1930 for firebars for the locomotive LLOYD GEORGE owned by the Ruthin Lime & Limestone Co at Denbigh: this locomotive has not been identified. Oakeley Slate Quarries ordered four sets of locomotive firebars on 8th February 1930, while the Aluminium Corporation Ltd of Dolgarrog received a quote in August 1929 for turning six locomotive wheels to the same diameter. In December 1928 Llechwedd Quarry asked the price of a cast iron plate 5ft 1in by 1ft 8in by 3in, one side planed, for the front end of a locomotive. Finally, in July 1936 Owen's fitter was at the Fairbourne Railway drawing the tubes from the "miniature locomotive".

Probably the most important loco work on which the foundry was engaged in recent times was the Votty & Bowydd battery locos, three of which were built. The earliest reference to Votty locomotives is a quote of 25th May 1934 for a shed, which could not be made high enough for a locomotive. In his notebook for about December 1936 Owen, who was also the foundry's traveller, noted that the disc wheels for the "loco" were 143/8in outside diameter (over tread?), 2¼in wide and bored for a 2½in axle. Spur wheels were to have 70 teeth and the note "2 off" suggests that Owen was to make them; pinion wheels were to have 17 teeth and be 35/8in diameter. Confirmation of this comes in a letter of 11th December 1936 in which Votty urged delivery of the pinions and spurs for the battery locomotives. Owen's notebook at this time includes a note of the address of Wingrove & Rogers, which firm has not hitherto been implicated in any of the Votty locomotives.

On 18th December 1936 Owen offered £1 10s (£1.50) for scrap at Votty. This included rails on two inclines, old wagons, and the "loco". Finally, under the heading "Votty Battery Loco" on 14th February 1937 Owen noted that the wheels were cast steel, 19in diameter over the flanges, 3in wide on the tread, with axles 2½in diameter. The length of the locomotive was 6ft over the buffers, the frames were gin deep at the ends, and the wheelbase was 2ft 4in. It is not clear whether this refers to an existing or a proposed locomotive, although the inclusion of frame dimensions may suggest that it was a proposed design. Can anyone who has measured any of the Votty locomotives say to which these measurements might refer?

It is not clear what to make of this Votty information. Certainly Owen had a hand in the building, or repair, of some (at least two) of Votty's four battery locomotives. It may also be that Wingrove & Rogers at least supplied electrical equipment; possibly some of the "home made" locomotives were in fact rebuilds by Votty and Owen of Wingrove & Rogers locomotives.

* Surviving Muir Hill records identify one of these locomotives as works number 24 of 1927, supplied new to Edmund Nuttall, Sons & Co Ltd for "new reservoir at Birmingham": The records of Thos. W. Ward Ltd, Charlton Works, Sheffield confirm this works number (although it is shown as 24c) and identify the second locomotive as Muir Hill A114. Both were purchased from Nuttall on 4th February 1930. 24 was then sold direct to Ward's Frodingham Slag Heap, Lincolnshire, on 17th February 1930, but A114 was taken away to Sheffield from where it was sold on 26th April 1930 to George Vickers of Kilburn, near Derby: the purchase price included £5 which was the cost of delivery to Scunthorpe.

Incline Drums

Incline drums, particularly those for powered inclines, were perhaps the most intricate and expensive of all the Britannia Foundry's products. Rollers and sheaves were among the subsidiary incline equipment for which repeat orders were regularly received. Most orders were for known railway operators, although an exception is the Mold Gravel Co, Rhual Quarry, Mold, which ordered incline rollers in December 1932.

The surviving letters record a surprising number of new incline drums ordered between 1927 and 1936 - surprising, since North Wales must then have contained around two hundred abandoned inclines. Perhaps the costs of dismantling and re‑erecting exceeded the price of new equipment. Certainly the prices for a simple gravity incline drum seem, by today's standards, very low. In 1929, the Corwen Slate Mining Co Ltd accepted Owen's quote of £29 10s (£29.50) for a drum 3ft 6in diameter and 8ft long, to the same pattern as one earlier supplied to T.O. Williams, a quarry owner of Llanbedr, Merioneth.

Prices rose rapidly as the diameter of the drum increased. In 1929 Carreg-y-Llam Quarries Ltd at Llithfaen were quoted £85 delivered for a drum 5ft 6in diameter, similar to one supplied in 1919 to Moel-y-gest quarry. Again in 1929, Owen visited the Park & Croesor slate quarries, where he was "surprised" to find that the brake wheel on the drum was worn and broken, while the walls of the drum house were leaning and in a dangerous condition. On 17th June he quoted Croesor Quarry £43 15s (£43.75) for a 9ft brake wheel, and this was later supplied. The highest price for a complete gravity drum was £105; this was in February 1929, to be 6ft diameter and delivered to Penmaenmawr & Welsh Granite Co Ltd at Trevor Quarry.

The smallest drum built appears to have been for Baines Bros, who worked a small slate quarry at Llantysilio, near Llangollen. This was to be 2ft 6in diameter, for an incline only 70 yards long. The only powered incline known to have been equipped by Owen during this decade is one at Maenofferen slate quarry where a new three-track incline was proposed in 1935. In this case, it is almost certain that Owen purchased the electric motor from elsewhere, and constructed only the mechanical parts.

Wagons

The surviving drawings include 27 different types of narrow gauge wagons. Eight have been redrawn (Figs 3 to 10) in order to show the range of work undertaken by the Foundry. These drawings, which are exact copies of the originals, are described in more detail below.

In the majority of cases in which the drawings are dated, they come from the period 1869-1875. Although this may be no more than a fraction of what has survived, the probability is that this period was one of expansion, in which many new basic designs were prepared. Thereafter, the Foundry probably managed by using these old drawings, making only occasional "rule of thumb" alterations.

It is hard to draw any general conclusions about the Britannia Foundry's wagon designs since, as mentioned earlier, they were the product of customer preference rather than foundry originality. About the only feature which is fairly common is the design of the axle pedestal: it seems usual for the radius at each horn base to meet the horizontal at a slight angle rather than a smooth curve, a very minor point.

Identification of the wagons built by North Wales foundries is hard since few (except DeWinton) carried makers' plates. In recent years, Britannia and Glaslyn took to stamping "E R O" and "C H W" on their wheels, many examples of which survive. This may well have been due to complaints from Votty & Bowydd quarries who bought from both foundries and had trouble with new wheels fracturing. They threatened to place their own mark on new wheels in order to identify the foundry responsible for the poor casting!

Fig 3 IRON RUBBISH-WAGON

Fig 3 The earliest drawing in the collection, dated December 1869, is from the first R. Williams era and is entitled "Iron Rubbish-Waggon for Tipping & Turning". The gauge is not specified, but would appear to have been 2ft 0in or slightly less. This was probably a wagon intended for slate quarries but, although the theory of the design was no doubt sensible, it seems unlikely that it would have stood up to much heavy work. The general design may be compared with the Kerr Stuart & Co Ltd wagon shown on page 315 of RECORD 45, which was intended to accomplish the same duties: It is notable that the Williams wagon was of relatively massive construction and used rollers running on a turntable track, although admittedly it was of 20cu ft capacity, double the Kerr Stuart design. Wheelbase of the wagon was 2ft 0in and the double-flanged wheels were 14in diameter over the treads.

Fig 4 END TIPPING AND TURNING WAGON

Fig 4 This rather novel 1ft 6in gauge wagon is depicted in a drawing of 29th November 1890 titled "End Tipping & Turning Wagon". It has a capacious body (25cu ft) made of 3/16in plates with an end door and a curious body retaining catch. If this were released, there would appear to have been an even chance of the body tipping before it could be swung round on its turntable! The wheelbase was 2ft 1in but the wheels were only 9in diameter.

The general design, the tiny wheels and the narrow gauge strongly suggest that this "Universal" tipper, as it was described, was intended for underground service in one of the local metal mines. There is no lack of candidates: in Merioneth, the Gwynfynydd mine of the Morgan Gold Mining Co Ltd was founded in 1888, Clogau gold mine was reopened in 1891, and Berthlwyd gold mine expanded in 1892‑3. Drws-y-coed copper mine, restarted about 1890, is another possibility, and numerous other examples may be mentioned.

Fig 5 CWMORTHIN INCLINE TRUCK

Fig 5 This drawing, dated 14th January 1873, is entitled "Truck for Incline Traffic for Cwmorthin Slate Quarry Co." and is typical of the general design of wagon used for carrying slate slabs on inclines in certain quarries. The end standards were of course intended to prevent the load coming adrift on the gradient. Curiously, however, although several quarries (notably Dinorwic) made use of similar wagons, which seem to be ideal for the job, a great many more relied upon the slab bogie of the type shown in Fig 8. This is one of the very few instances of a specific design of incline truck at Blaenau Ffestiniog that has come to my notice.

Several modifications have been made to the drawing, principally reducing the wheelbase to 2ft 9in and lessening the slope of the end stays. The end elevation shows the addition of two vertical straps. Woodwork was to be mainly of oak, except for deal boards 9in by 1¼in by 3ft 0in for the deck. In passing, it may be noted that 42 bolts of 13 different types were required to build even such a simple wagon as this.

Fig 6 WOODEN TIP WAGON

Fig 6 A wagon from the J.H. Williams era, this drawing is dated 17th November 1873. Described as a "Wooden Tip Waggon", its gauge of 2ft 6in and the name of the customer - Johnson & Co, London - make it a rather intriguing design. It had wheels 1ft 5in diameter with a wheelbase of 3ft 3in and a rather low overall height of only 4ft 0in from rail level. The body capacity was fairly large (26cu ft) and it will be noticed that the wagon was designed to tip on either side. The centrally pivoted "legs" were shod with iron at the bottom and apparently had a pin through the top. To tip the wagon, presumably the pins would be removed and the appropriate legs knocked out. It is an extremely odd arrangement, and one would have thought that a pair of heavy restraining chains would have been somewhat more robust. My suggestion would be that "Johnson & Co" refers to Isaac Charles Johnson & Co who operated Greenhithe Cement Works in North Kent at this period, although 2ft 6in was not a common gauge in the cement industry. It would be nice to know more.

Fig 7 WOODEN SLATE WAGON

Fig 7 The original of this drawing, dated 20th July 1874 and unhelpfully titled "Wooden Slate Wagon", presents several problems. The general design, with wooden slats separated by cast iron spacers, was common in North Wales, at Dinorwic slate quarry, and on the Festiniog Railway and at the quarries it served. Only the body work has been inked in on the original drawing, the wheels and pedestals being in pencil only and perhaps added at a later date. The wheelbase scales 3ft 2in while the rail gauge is, at minimum, 2ft 2in. Pencilled in is a note that the wheelbase of the "Park Quarry Wagon" was 3ft 3in. Errors of up to 2in would not be expected on a large (1½in to 1ft) scale drawing, and the assumption would be that, particularly as regards the gauge, the drawing is correct. Perhaps 2ft 3in gauge (e.g. Corris or Talyllyn railways) was intended.

Another pencilled note gives dimensions of Festiniog Railway wagons, which are stated to be 5ft 3in long by 2ft 8in wide, with wheels at 3ft 4in centres. The first two dimensions are very much smaller than those of this drawing, but agree almost exactly with those average dimensions quoted by J.I.C. Boyd in "The Festiniog Railway" (Volume 1, page 153). The axle pedestals are, however, totally dissimilar to the Festiniog type. The only other "clue" to the customer of this design is that the draughtsman experimented with the letters "R" and "M" in various ornate styles, and pencilled in an "M" on the solebar. Does this suggest anything to readers?

Fig 8 SLAB TROLLEY

Fig 8 Titled "Slab Trolley for Messrs. Ashton & Green", this drawing is dated 22nd April 1875. The wagon is of fairly simple design, used for carrying blocks of slate, and its principal dimensions are: overall length 4ft 6in; width over frames 1ft 7in; width over bearers 3ft 0in; wheels 1ft 2in diameter over treads (approximately); and wheelbase 1ft 11in. The four bearers - many such wagons had only three, the fact being noted on the drawing - were faced with sheet iron 2¾in wide and 3/8in thick. It was usual to dispense with the centre frame spacer, the bearers and the end two transverse members providing sufficient rigidity. I am not certain which quarry Ashton & Green owned. However, other wagons to this design were requested by Rhosydd slate quarry. A note of 25th June 1881 required their wagons to have a frame 7in deep (rather than 6½in) and the whole wagon to be lowered. This was to be done by cutting recesses for the axle pedestals.

|

|

|

| Fig 9 SLAB TROLLEY | Fig 10 RUBBISH WAGON |

Figs 9 & 10 The first of these two designs, both of which were in production probably from the 1920's onward, represent the modern equivalent of the slab trolley shown in Fig 8. Fig 10 is the rubbish wagon variation, using virtually the same frame. In each case the wheels were 1ft 3in over the tread, and the wheelbase 1ft 11in. It is easy to see the functional simplicity in each of these designs, particularly with regard to building them compared to the wooden equivalent in Fig 8. Curiously enough, though, very few of these steel slab wagons exist. Most of the remaining slate quarry railways make predominant use of the wooden type, while surviving rubbish wagons are more usually wooden framed. It can be mentioned that the trolley or bogie was very often termed a "clog wagon", particularly by the Lake District quarries, "clog" being the name given to the raw block of slate.

In conclusion, I am pleased to acknowledge the help of D.C. Clayton, K.P. Plant, E.S. Tonks and W.K. Williams.

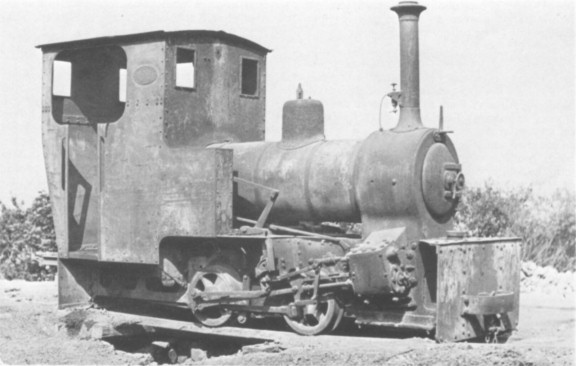

Frank Jones has forwarded this photograph in the hope that someone may be able to assist in identifying the locomotive and its location. The original was taken by the late F.G. Carrier, an enthusiast who lived near Derby, and it is thought that the photograph was taken in this area. Ron Redman informs us that Hudswell Clarke 1161 of 1915 is the only one of the type recorded in the Midlands. (This was a 2ft gauge 0‑4‑0 well tank, with 5in by 8in cylinders, delivered new to Harper Bros & Co to assist with the construction of the War Department camp at Richmond, Yorks: it was later recorded by the builders (no date) with A.H. Price & Co, contractors, Nottingham.) Just to confuse the issue, close scrutiny of the worksplate on the original suggests the date to be 1914!

'A difficulty with twenty-eight locomotive men of the Tredegar Iron Company has been settled. They abstained from work without notice on the 15th inst., and summonses were issued. On Monday the prosecution applied to have them withdrawn, the men having expressed their regret and returned to work.' ("The Engineer'; 23rd November 1900. - CGD)

'In addition to steel rails, considerable contracts for locomotives and wagons have been placed in Sheffield to Russian orders.' ("Bristol Evening News,"4th December 1877. - CGD)

Tenders invited for the "supply of 150 sets of wheels and axles for 10‑ton waggons, to the London and North-western present specification, and inspection. Delivery over present year. Address, Messrs, Richard Evans & Co, Limited, Haydock Collieries, near St. Helens." ("Iron," 20th May 1892. - KPP)