| THE INDUSTRIAL RAILWAY RECORD |

© JUNE 1973 |

AVELING & PORTER'S

TRAMWAY LOCOMOTIVES

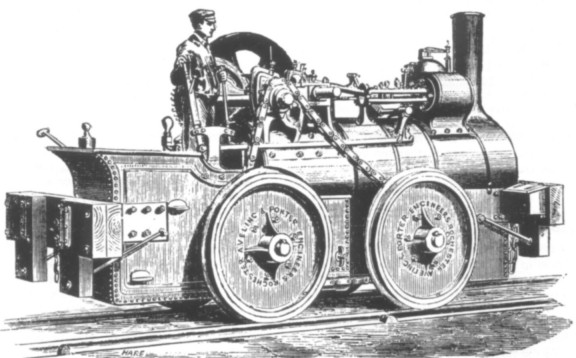

'In almost all parts of the kingdom there are to be found, in connection with mines and quarries, tramways, some of them of considerable length. Within the last few years the horse power which was formerly employed for working these lines has, in a number of instances, been replaced by locomotives, and the cost of traction has thereby been materially reduced. In answer to the demand thus created, a number of engine-makers have brought out designs for small locomotives more or less specially adapted to the work to be performed, and amongst these is that of Messrs. Aveling and Porter, of which we give a perspective view in the accompanying engraving.

'Messrs. Aveling and Porter are well known as successful makers of traction engines, and in their tramway locomotives they have adhered in many points to their usual plan of construction for road engines. In fact their locomotives may be described as a traction engine placed upon railway wheels, these wheels being coupled by the pitch chain which is employed to communicate the motion to them. Our illustration represents one of three engines of this class supplied by Messrs. Aveling and Porter to the Grays Chalk Quarries Company, at whose works they are now regularly employed. The engine is rated at 10 horse power nominal, and has a single cylinder 10in. in diameter, with a 12in. stroke, this cylinder being fixed on the top of the boiler and surrounded by a steam jacket, as in Messrs. Aveling's other engines. From the crank-shaft the motion is communicated by spur gearing to a countershaft carrying at its end the wheel for the pitch chain, the bearings of this shaft being placed in curved slots formed in the supporting brackets, so that the shaft can be raised and the chain tightened when necessary. The crank-shaft carries a flywheel, and the engine is fitted with the usual link-motion reversing gear.

The engraving which appeared in 'Engineering, 3rd August 1866.

'The pitch chain extends from the countershaft round the chain wheels fixed one inside each of the carrying wheels, and the chain thus couples the wheels together as well as communicates the motion of the countershaft to them. The carrying wheels are 4ft. in diameter, and are placed at a distance of 5ft. 3in. apart from centre to centre, the leading axle passing under the barrel of the boiler, and the trailing one being placed behind the firebox casing. The wheels are of cast iron, and the tyres of Naylor, Vickers, and Co.'s steel. The total weight of the engine is 9 tons, and this weight is equally distributed between the two axles. There are no springs.

'The boiler is of the ordinary locomotive class, and contains 60 tubes 2¼in. in diameter outside, and 5ft. 6in. long, these giving an external heating surface of 194 square feet. The firebox is 3ft. long by 2ft. in. wide and 2ft 7in high, and deducting the space taken up by the firehole door, &c., it consequently has a heating surface of about 28 square feet, making the total heating surface of 222 square feet. The firegrate area is 7¾ square feet, and the boiler is usually worked at a pressure of 801b. per square inch. The boiler is fed by a pump worked by an eccentric on the crank-shaft, and the feed-water is carried in a couple of tanks, one placed at the leading and the other at the trailing end of the engine, these tanks holding together about 350 gallons. The fuel is carried in a coal bunker formed on the footplate behind the firebox, sufficient space being provided to accommodate from 10cwt. to 20cwt. of coal, according to the mode of packing.

'At Grays the line leading from the quarries to the wharfs is about a mile in length, and is laid to the 4ft. 8½in. gauge. At the quarries it divides into two branches, one of these having a heavy incline of from 1 in 36 to 1 in 41 against the traffic, the incline being, moreover, situated where the line makes a series of reverse curves. The other branch has also a steep incline where it leaves the pits. On the branch first mentioned the regular load of each engine consists of fifteen wagons weighing about 1¼ tons each, and each containing 1¾ tons of chalk, the total load thus being 45 tons in addition to the weight of the engines. The engines are, however, capable of taking twenty of the loaded wagons up the bank, and a still heavier load had been drawn in some instances. On the other branch the load of each engine also consists of fifteen wagons, but in this case the wagons are heavier, weighing 30cwt. each, and they are each loaded with 2¼ tons of chalk. In this case, therefore, the total regular load is 56¼ tons besides the weight of the engine. Two of the engines supplied by Messrs. Aveling and Porter to the Grays quarries replaced two other locomotives previously at work there, and the saving effected by the change had been very great. During one week last year the two engines formerly used conveyed 3138 tons of material from the quarries to the wharf, with a consumption of 141½ cwt. of coal, the fuel consumed being thus equal to 5lb. per ton drawn. On the other hand, two of Messrs. Aveling and Porter's engines transported during the corresponding week of the present year 5100 tons of material with a consumption of 125cwt. of coal, the expenditure of fuel being in this case equal to rather less than 2¾lb. of coal per ton hauled. It is estimated that this difference in the quantity of coal required to perform a given work will save the company upwards of £260 per annum in their expenditure for fuel alone, and a very considerable additional saving is also effected in wages, the present engines being worked by ordinary labourers instead of skilled drivers. The price of each engine was £530 and they can be used as ordinary portable engines for working pumps, &c., if required.

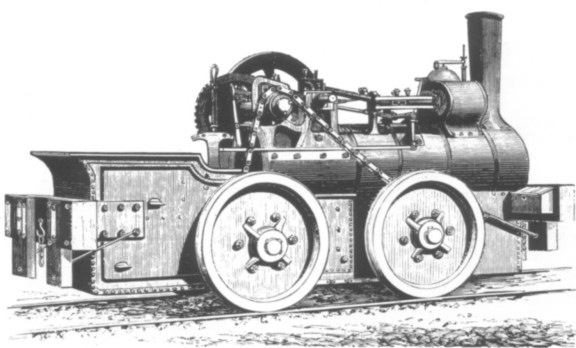

The much simpler engraving which was published in 'The Engineer, 3rd August 1866. The most obvious difference, of course, is the omission of the driver, but scrutiny of the actual machine reveals several items missing; in particular the various implements on the tender and the lettering on the wheels. Note also that the firebox water space mud-hole (between the wheels) on the 'Engineering' engraving is shown as what appears to be a taper plug.

'In addition to the engines at the Grays quarries, Messrs. Aveling and Porter have made a number of others for various places, amongst them two for the Royal Dockyards at Chatham and Devonport, as well as one for Portsmouth, now in hand. One for the 3ft. gauge has also been sent to Brisbane, the wheels for the pitch chains being in this case placed outside the carrying-wheels, and one for the 5ft. 6in. gauge is being made for India. At Devonport the engine (which is of 10 h.p.) has been working regularly on rails weighing from 36 to 42lb. per yard, its daily consumption being about 5cwt. of coals; and at the Hailing Lime Works, one of these engines has been for some time working on inclines of 1 in 20 and 1 in 12, the load in the former case being 5 and in the latter 4 tons. At the Lamb Wharf Chalk Works, Greenhithe, these engines are also in use. The line leading from the cliff to the wharf is about a quarter of a mile long, and rises 1 in 100. Up this bank one of the engines can take thirty loaded wagons, each weighing 2¼ tons; it is found, however, more convenient to work regular trains of ten wagons. The consumption of fuel is about 1½lb. of Hartley's coals per ton transported. Altogether these engines have given abundant evidence of being well adapted for use in quarries and similar places where heavy loads have to be moved at slow speeds, and in such situations it appears that they will do the work at about half the cost incurred by the employment of horse power.'

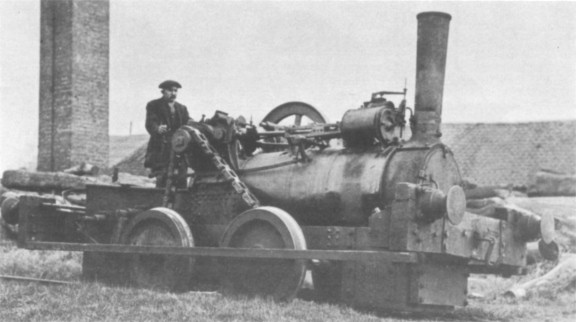

Aveling & Porter 807 of 1872 at Nether Heyford Brickworks on 11th April 1936. There seems to be very little clearance between the front water tank and the track ballast (G. Alliez)

("Engineering'; 3rd August 1866. Reference in the article to the Avelings replacing 'two other locomotives previously at work' is intriguing, for Pocket Book C (page C 101) lists three locos at Grays Quarries Co Ltd before the Avelings. These were BRISTOL, an outside cylinder 0−4−0 saddle tank built by Slaughter Gruning in 1852; OPHIR, an inside cylinder 2−2−0 well tank by George England; and PUGSY, an inside cylinder 0−4−0 saddle tank of unknown make. All three are shown as passing to I. W Boulton, Ashton-under-Lyne, in 1866, by which time Grays had taken delivery of three Aveling & Porter locomotives – works numbers 121, 151 and 167. It would seem likely that disposal of these Avelings occurred sometime after the late 1890's, when Grays obtained some Brush and Bagnall locomotives of more conventional design. Definite details, however, are lacking.

The appearance of this feature on Aveling & Porter locomotives obviously coincided with Aveling's entry into the field of rail locomotive construction: indeed, works number 121 (cited above) was the very first they built. Information from Society records, supplied by W.K. Williams, shows that only fourteen Aveling locos were built up to the end of 1866. The list shows all three Admiralty machines – works numbers 129, 182 and 218 – as going to (? or ordered by) the Chatham Dockyard, Kent. It seems probable that two of these were in fact delivered directly elsewhere – one each to Devonport Dockyard, Devon, and Portsmouth Dockyard, Hants. We appear to have no knowledge of the locomotives at 'the Lamb Wharf Chalk Works, Greenhithe, nor the one at Walling Lime Works: However, it is known that Thos. & Wm. Weekes, Halling, Kent, did own a narrow gauge Aveling & Porter locomotive which was later rebuilt by themselves: the original works number is not known.

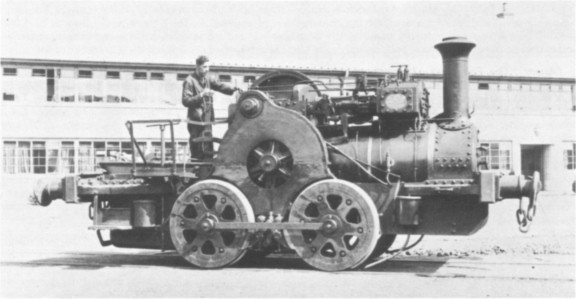

Later Aveling & Porter compound locomotives were basically the same as that depicted by the engraving, but the pitch chain drive was replaced by an intermediate gear which drove on to the axle gears. Typical of these was Aveling & Porter 4399 of 1899 seen here at Aveling-Barford Ltd., Grantham, on 3rd July 1937. Note that the rod connecting the two axles is not a coupling rod! (G. Alliez)

'The Engineer' of 3rd August 1866 also ran a short article on the Avelings at Grays, but the engraving they featured – based presumably on similar photographs to those 'Engineering' would have used – was altogether more simplified. This in itself is worthy of note, for it is clear evidence that engravings can never really be taken at face value, often being subject to considerable artistic licence. Also, while usually based on photographs of actual locomotives, engravings of non-existent types could be produced by capable engravers to suit the whims of locomotive manufacturers bent on capturing the attention of would-be customers. Although having less to say about the locomotive, 'The Engineer' pointed out its advantage when used on 'lines on brick fields, quarries, mines or temporary lines on public works' At least one brickworks obtained two such locomotives. One of the photographs shows Aveling & Porter 807 of 1872 at the Nether Heyford Brickworks (Northamptonshire) of Henry Martin Ltd. The engine was one of a pair which were obtained by the Blisworth & Stowe Brick & Tile Co Ltd – Martin's predecessors – from the Oxford & Aylesbury Tramroad Co in 1894. Originally supplied in January 1872 to the Duke of Buckingham (for the Oxford & Aylesbury Tramroad), 807 had a single cylinder (7¾in by 10in) and was carried on wheels of 3ft 0in diameter. Other small variations from the engraving model will be noted – for example the spring buffers and crude running board, both probably later additions. The brickworks closed in 1940 but was used as an ammunition store by the War Department. Happily, 807 survived the War, being stored until March 1951. It was then secured by the Industrial Locomotive Society, and is now on display at the Museum of British Transport, Clapham. Acknowledgements are due to J. B. Latham and the Industrial Locomotive Society for details supplied concerning the George Alliez photographs reproduced herewith.

— TJL).'Mr. Kitson established the first foundry in Leeds for the making of locomotives in 1836. He had previously had some experience in constructing railway material at Hunslet; but in the year mentioned, in the lower room of an old cloth-mill, where a pair of woollen looms were in operation, he began to build his first locomotive. Much curiosity was evinced in Mr. Kitson's work, and he was joked upon the fact that there was no doorway large enough for the egress of the engine. This was but a small detail, however; and when the locomotive was finished Mr. Kitson broke down a portion of the wall, and the engine was soon put upon its travels out in the open country. Orders for more locomotives came in; and before long the cloth-weavers were ejected from the mill, and Mr. Kitson entered into full possession of the building, and the Railway Foundry (which was subsequently merged in the larger Airedale Foundry) soon became one of the leading industrial establishments of the town. The Airedale Foundry of to-day –comprises about ten acres of ground, and is capable of turning out about eighty locomotives. Mr. Kitson was a worthy pioneer; he opened a new and profitable mechanical business to Leeds; and in the course of time others followed in his footsteps, and locomotive building became an important trade. Messrs. Manning, Wardle & Co. subsequently attained a position of eminence amongst Leeds locomotive makers: and the Monk Bridge Ironworks, carried on by Messrs. Frederick & James Kitson, sons of the originator of the Railway Foundry, supply large quantities of material for the construction of engines. In 1857 there were upwards of 4,000 persons engaged in Leeds in the manufacture of stationary and locomotive engines and railway material; and in the last twenty years have considerably extended the productive capacity of these branches of industry.'

(Anon: "The Fairbairns of Manchester and Leeds" in "Fortunes Made in Business" [Sampson Low, Marston, Searle & Rivington, 18841 Vol II, pp267-268. In "The Railway Foundry Leeds 1839-1969" R N Redman states that it was 1837 (not 1836) that James Kitson went into partnership with Charles Todd and David Laird. LION, the first locomotive built by Todd, Kitson & Laird, was one of a pair of 0−4−2 tender engines supplied to the Liverpool & Manchester Railway in 1838. Rather fortuitously, LION still exists today in preservation at the Liverpool Transport Museum.

— KPP)'The Airedale Foundry of Messrs. Kitson [, Thompson] and Hewitson is one of the greatest manufactories for the construction of locomotives in the kingdom, in which no less than 1,000 hands find constant employment. ... The premises are very extensive, nearly four acres of ground being covered by them. The Midland Railway have run a branch line into the centre of the works, a necessary accomodation for the proprietors.'

(From "The Official Illustrated Guide to the Great Northern Railway, "published by George Measom in 1861.

— KPP)'THE SCEAUX RAILWAY, one of the most peculiar lines in Europe, has ceased to exist. It connected Paris with Sceaux, a town a few miles south of the French capital. Many were the jokes about the "chemin de fer circulaire," so-called because on arriving at their destination the trains turned round in a complete circle in a garden, and started on the return journey. The carriages were almost like toy carriages, open at the sides, and the engines, which weighed a couple of tons, were specially made for hill-climbing, the gradients being very steep. The line has now been rebuilt, new and powerful engines have been made, and the terminus henceforth will be at the pleasure-resort known as Robinson, about a mile distant.'

("Iron, "26th May 1893. Details of the locomotives would be welcome. — KPP).