| THE INDUSTRIAL RAILWAY RECORD |

© DECEMBER 1971 |

THE ORIGINS OF ORENSTEIN & KOPPEL

F. KEMPER

At the Paris World Exposition of 1878 visitors were introduced to a new type of portable track for agricultural purposes: the Decauville Light Railway System. Paul Decauville had been forced to this invention in the autumn of 1875, when a harvest of 9,000 tons of beet on his farm in France seemed lost by heavy rains. Decauville put down some light rails on square iron sheets, and spaced the rails at a gauge of 400mm. The sections were so light that they could easily be carried and laid down by two men. Small four-wheeled wagons enabled the harvest to be gathered in record time. A year later Decauville widened the gauge to 500mm and employed steam locomotives of 4 tons weight in working order. The judges of Expo 1878 were so impressed with this new invention that they awarded it a gold medal.

Among the many visitors to this exhibition was a young businessman from Berlin named Arthur Koppel. He saw at once the great opportunities that the portable railway system would offer to the large estates in Eastern Europe and Russia which were then considered to be the greatest granaries of the world, and decided right then and there to sell and eventually manufacture this light railway material. So it happened that Germany became the second country after France to lead in the development of portable and permanent light railways.

Unfortunately, the actual date of foundation of Arthur Koppel's firm is not known but from the album of 1897, which is the earliest on hand, we can presume that this date should be looked for in the early 1880's. A loose connection between Arthur Koppel and Benno Orenstein had existed since 1876 but it is evident that Koppel wanted to establish himself in a business of his own. For a number of years even a third firm connected with his name appeared on the market, that of Gutfeld & Koppel, but it soon faded out of the picture. All these firms were trading at first in light railway materials which were bought from different iron works. However, inventions and improvements to light railway equipment and booming business forced the industry to acquire manufacturing plants of its own.

Just like Decauville, Arthur Koppel was not missing out on a single exhibition taking place anywhere in the world, and beginning in 1886 diplomas and medals were showered on the firm. Around 1890 Koppel was already a world institution with works in Bochum and Camen, Germany, and branches at Brussels, Bucharest, Cairo, Hamburg, Johannesburg, London, Madrid, Moscow, New York, Paris and St. Petersburg. A publication of 1900 which shows photographs of fifty-nine light railway installations in all parts of the world indicates the notable increase in business with Russia by announcing the opening of additional branches in Riga, Helsinki, Warsaw, Odessa and Vladivostok. In view of both the growing demand and the great rise of import duty the necessity of creating manufacturing facilities in Russia became inevitable. The new works built in 1897 and located at St. Petersburg carried the name ‘Joint-Stock Company for the Construction of Economical Means of Transport and Mechanical Appliances on Arthur Koppel's System’.

Reflecting the general trend of the Company's business, Arthur Koppel not only increased steadily the deliveries of light railway equipment but became a notable builder of light railways as well. Outstanding in Russia was the construction of a 750mm gauge forest railway in the Ural Mountains, 116km (72 miles) in length. Before that the engineering staff of Arthur Koppel had laid down some 200km (125 miles) of plantation railways for the Société Générale des Sucreries de la Haute Egypt. The biggest job, however, was the construction of the Otavi Railway in South-West Africa. With a length of 360 miles it was then considered to be the longest 600mm gauge railway in the world. Having been built between 1903 and 1906 it may justly be called the crowning of the lifework of Arthur Koppel. Two years later, in 1908, Arthur Koppel died in Berlin and his firm ceased to be an independent unit when it was amalgamated with Orenstein £t Koppel.

On page 29 of RECORD 23 the Editors asked: 'Did Arthur Koppel ever build locos? Or did he only supply them?' Well, from the facts mentioned above we can easily see that it could not have been the intention of Koppel at any time to enter the branch of locomotive building. His French model, Decauville, had done so but we know that the locomotive department there never amounted to much, relying often on outside firms to supply boilers and even complete locomotives. Koppel was too clever a businessman to put money into locomotive manufacturing when he could buy cheaper in an already highly competitive market. Since 1867 Krauss of Munich had specialized in the production of small steam locomotives; they were joined in 1885 by Arnold Jung. Both firms were soon to dominate the market for small locomotives, since Arthur Koppel needed them to be supplied along with his light railway equipment. Competition was so keen already that the firms had to agree to deliver the locos with Arthur Koppel plates on the cabsides, although their own plates had to appear on the firebox backplates according to German boiler inspection laws. So came about the mystery of Arthur Koppel locomotives'.

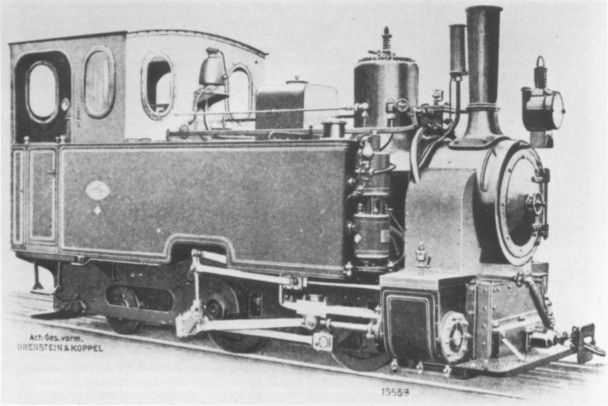

The frontispiece of the first catalogue issued by Maerkische Lokomotiv-Fabrik, predecessor of Orenstein & Koppel.

As far as can be seen, Arthur Koppel bought his first locomotive from Krauss of Munich in 1885 (Krauss no. 1626). It was a small 0‑4‑0 well tank of 600mm gauge. Subsequently we find his name on the lists of many a locomotive manufacturer, even American. For example nos. 93 and 94, the two 0‑4‑2 saddle tank locomotives of South African Railways class NG2, carried plates on the cabsides with the inscription: ‘DICKSON Manf’g Co., Sole Agents for South Africa Arthur Koppel, Johannesburg’. This raises the question as to why Koppel did not buy his locomotives principally from Orenstein & Koppel once this firm had started to build them. The answer is to be found in the history of A. Koppel whose main interest centred in the sale and installation of light railway equipment. Locomotives were only included in the offer when the customer wanted them to be part of the contract. But in such cases A. Koppel had to inquire in many places to find locomotives best adapted to the needs his of customers, and in the course of years certain business connections with locomotive manufacturers had developed that could not easily be interrupted.

Nevertheless, the idea of branching out into locomotive manufacturing had apparently been contemplated for some time by the Orenstein/Koppel families. In 1890 the first attempt in this direction was made when Max Orenstein was sent forward to establish the Maerkische Lokomotiv-Fabrik in Schlachtensee, near Berlin. It is a pity that we have not the slightest idea of what this locomotive factory looked like. Not the smallest picture or drawing has been left to posterity. From Orenstein & Koppel's records it can be estimated that the annual capacity of this early plant was about thirty small locomotives. Besides locomotives, Max Orenstein took up the manufacture of modern bearings for replacement on older light railway stock, and it seems that this sideline kept the works going for the first few years. The first locomotive left the works on 2nd November 1892. It was a contractor's 0‑4‑0 tank loco of 80hp and 900mm gauge. Strange as it seems, the first locomotive showed plates with the works number 5! This can be no mistake as the later Orenstein & Koppel records leave the pages 1 to 4 blank indicating that no such locos with these numbers were built. After all, Max Orenstein was not the first nor the last to be ashamed to start manufacturing at works number 1.

In the spring of 1892 the Maerkische Locomotiv-Fabrik issued its first (and probably only) publication which was a strange mixture of catalogue and pocket book. On 133 pages all kinds of problems connected with light railways were discussed, even the then antiquated German laws as well as letters of thanks from satisfied customers. In spite of the fact that the frontispiece carried the title ‘Leichte Lokomotiven’ (Light Locomotives) no such engines of its own manufacture could be shown as none had been built so far. Instead the catalogues of other firms, mainly American, had been ransacked; in some cases the artist had not even troubled to retouch the plate of the H. K. Porter Company. The strangest thing, however, was that this booklet was not given away to prospective customers but had to be bought in a book shop for 1½ marks which was quite a lot of money in those days.

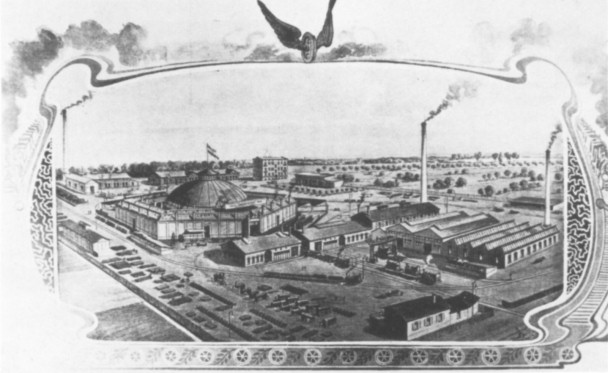

But let us return to Orenstein & Koppel. This firm had set up in 1893 a factory at Dorstfeld, near Dortmund, for the manufacture of light railway equipment. To raise additional funds from the money market the company went public under the name ‘Aktiengesellschaft für Feld - and Kleinbahnen - Bedarf vormals Orenstein & Koppel, Werk Dortmund - Dorstfeld’ (Joint-Stock Company for Light Railway Equipment formerly Orenstein & Koppel, Dortmund works, Dorstfeld). Towards the end of the 19th century the company decided to go into locomotive manufacturing and built a new works at Drewitz, near Potsdam, also in the vicinity of Berlin. In 1898 the Maerkische Lokomotiv-Fabrik was bought and the staff, machine tools and the goodwill were transferred from Schlachtensee to Drewitz. Here the new buildings covered a surface of 13,000sq ft and the works were laid out for an annual capacity of 300 locomotives, each up to an empty weight of 50 tons. The strangest, and unique, building was the centrally located erecting shop; in this circular, dome-covered building all tracks for locomotive erection pointed to the centre. The distribution of all parts and the shipment of finished locos was done by two radially working travelling cranes. It was inevitable that this building soon became known among Orenstein & Koppel men as ‘Der Zirkus’ (The Circus).

Laying out a locomotive works for a certain capacity and achieving the goal of actual output is quite a different thing, as is well known from locomotive history. The locomotive construction of Orenstein & Koppel showed no exception to this rule. During the first full year of activity (1899) only about 100 locomotives were built, but this figure was doubled in the following year. Dropping and rising again in subsequent years the production goal was finally reached in 1905. From then on business went up rather steeply so that the catalogue of 1908 could already announce a yearly capacity of 600 locomotives. The zenith of production before World War I was reached in 1912 when no less than 659 locomotives were outshopped.

The new Drewitz locomotive factory, as built in 1898. In the centre is tine famous circus-shaped erecting shop.

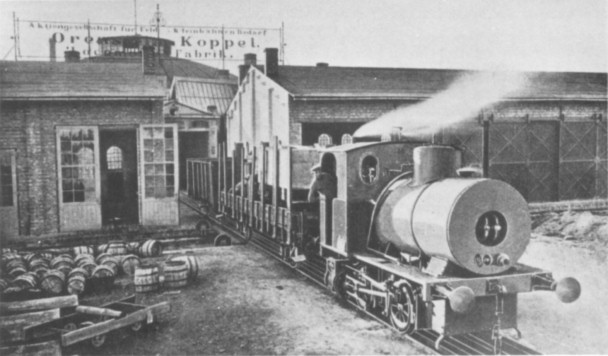

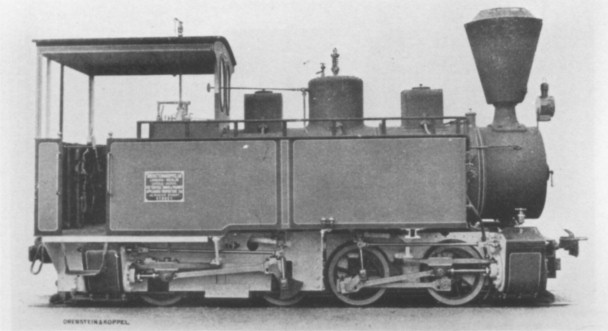

An Orenstein & Koppel fireless locomotive shunting at the Drewitz works in 1899. Note the multi-gauge test track for trial running.

Orenstein & Koppel 591, an 80hp 600mm gauge locomotive, was supplied to the Walluecke Iron Ore Railway, Germany, in 1901.

This 2ft gauge wood-burning Mini-Mallet shipped to Sydney, Australia, weighed 18 tons in working order and was rated at 110hp. The plate on the cab side reads: ORENSTEIN & KOPPEL Ltd LONDON-BERLIN GENERAL-AGENTS THE 'CENTRAL'MINING & TRAMWAY APPLIANCES PROPRIETARY Ltd 40, HUNTER STREET, SYDNEY.

ROODEPORT UNITED M.R. No. 2 (Orenstein & Koppel 696 of 1901), a 2ft gauge 30hp locomotive, was shipped to Johannesburg, South Africa.

What did these locomotives look like? Certainly most of them were in the 20hp to 100hp range but this does not mean that they were all dull affairs of 0‑4‑0 or 0‑6‑0 wheel arrangement. For example, a number of most interesting Mini-Mallet tank locomotives were designed at Drewitz whereby the cylinders of the fixed rear trucks were located under the driver's cab and worked backwards while the loco was running chimney first. Also, in the matter of valve gears Orenstein & Koppel went their own way. Patented in 1900 their own valve gear was fitted to an ever increasing number of their engines. It belonged to the class of radial gears having no reversing link and was based, like the Joy gear, on Hackworth.

One more word about works numbers. The numbering of the Maerkische Locomotiv-Fabrik was continued when this firm was bought in 1898, but no break or remark can be detected in Orenstein & Koppel records. It is generally thought that such a division should be looked for in the vicinity of works number 150. Many locomotive historians all over the world have searched for an Orenstein & Koppel works list but have failed to locate one. The reason is simple: there never was one. Instead the Company kept a spare parts list for every locomotive showing on the left and right page of a large bound volume all drawing numbers of such parts which were subject to wear and tear. To my knowledge no other locomotive factory in the world went through such trouble to keep track of their orders. All 64 volumes have been salvaged by our good friend Mr Arndt and deposited in the Dresden Transport Museum, but you will understand, I hope, that no one person will ever have the time and the opportunity to copy out this large work.