| THE INDUSTRIAL RAILWAY RECORD |

© DECEMBER 1967 |

FRINDSBURY CEMENT WORKS

C. G. DOWN

The manufacture of cement in its various forms is a very old industry. The Egyptians had a form of cement prior to 2000 BC while the Greek and Roman civilizations also used cement as a mortar and plaster. In Britain, John Smeaton was the first to use a practical cement, in his third Eddystone Lighthouse. In 1824, Joseph Aspdin, a Leeds bricklayer, took out a patent for what is now called Portland Cement, and set up his own works at Northfleet on the Thames, on what is now the site of Bevan’s Works.

In the South, there are two great cement producing areas, along both banks of the Thames estuary and the River Medway, and it is on the latter that the Frindsbury complex of works was established. The area consisted of an inverted delta of chalk hills, highest at the base and falling off to mud flats and saltings on the two sides where it is bounded by the River Medway. The first sign of industry in the area was the construction of the Thames-Medway canal, the tunnel of which the North Kent Railway later utilised to reach Strood Station in 1849. Whether the railway influenced the development of the cement industry at all is doubtful – certainly physical rail connection with the industry was not established for nearly eighty years, though it had been mooted for many years previously.

It might be best to deal separately with the seven works which passed to Associated Portland Cement Manufacturers (1900) Ltd.

CROWN WORKS was the first works in the area, being established in 1851 by William Tingey. He leased most of the western shore and inland area from the Ecclesiastical Commissioners and the Rochester Bridge Wardens, though using only a small portion of the land himself. On the rest, he built works and sublet them as going concerns, it being easier to let the works than the empty land. He specified in the leases that the works should only obtain their chalk through him, a clause which caused many years of bitter relationships between all the firms. A.P.C.M.(1909) Ltd. took over the works on 13th December 1900.

PHOENIX WORKS was the first of the works to be sublet. The land was leased about 1863 by James Benjamin Parker, but Tingey doesn’t seem to have put up the works until 1875. In this year, Parker formed the Phoenix Portland Cement Company and took out a lease on the works on 29th September 1875. In 1889, Phoenix leased additional land and extended the works which subsequently degenerated; when sold to A.P.C.M.(1900) Ltd. on 25th October 1900, the works was more or less abandoned.

GLOBE WORKS. Tingey sublet more land just south of the Phoenix works on 10th June 1880 to John Cubitt Gostling, who later formed the Globe Portland Cement & Whiting Co. Ltd. Gostling was also owner of a Thames-side Cement Works, and, due to quarrying disputes at Frindsbury, barged down 1,021 tons of chalk from his other quarries between 30th November 1893 and 7th February 1894. (There is a possibility that he was forced to do this owing to a fire on 22nd June 1893 which destroyed three-quarters of the Medway works.) In 1895, the works was purchased by John Bazely White & Bros. Ltd., owners of the giant Swanscombe Works on the Thames. Due to the recession in the industry though, the works was not used much subsequently, and was bought by A.P.C.M.(1900) Ltd. on 24th August 1900.

QUARRY WORKS. The history of this works is uncertain; it was probably put up in 1889 by the Gillingham Portland Cement Co. Ltd. In June 1893, the Company built a new works on the Thames rather than develop Quarry, owing to the difficulties of chalk supply. The works was also purchased by J. Bazely White & Bros. Ltd., in 1897 this time, and passed to A.P.C.M. (1900) Ltd. on 24th August 1900.

BEEHIVE and BEAVER WORKS were built by Tingey on the Bridge Warden’s land and leased on 2nd December 1890 to William Levett & Company (Beehive) and McLean & Co. Ltd. (Beaver). Soon after 1893 the two joined forces to form the firm of McLean, Levett & Company, who managed the works through several years of intermittent production until taken over by A.P.C.M. (1900) Ltd. about 1900.

* * *

With so much industry within ⅜ mile of river front, it might be expected that disputes arose. The few that did, however, were due to the complicated arrangements for chalk supply that existed and plagued the area for much of its life.

Originally, as has been mentioned, Tingey specified that the works should obtain their chalk from him. He performed his own quarrying in the area of his works and later, when this was exhausted, took to barging chalk down from his Wouldham Quarries (the Rochester Chalk Co. Ltd.), a few miles up−river. But the lessors of the land (the Ecclesiastical Commissioners) seem to have appointed a common quarrier, doubtless imagining that this would be a more efficient arrangement than for the individual owners to quarry themselves.

Consequently, in about 1863, John Cole was quarrying in the area. It seems that Phoenix soon broke the terms of its lease and took chalk from Cole. In 1878 Cole died and was succeeded by William Ball; on 30th December 1879 the Ecclesiastical Commissioners agreed to rent the land to Ball for an annual rental of £100 plus 5d per ton on the chalk quarried. As other works were put up, the complaints grew in number, both about the restrictions imposed by Tingey (for he controlled physical access to the works) and about the chalk prices charged by Ball. It does seem fairly certain that Ball was trying to some extent to drive the manufacturers out of business. He could then put up his own works and manufacture at a much lower cost. But for the depression of the industry in general, and the formation of A.P.C.M. (1900) Ltd., he might even have succeeded.

Ultimately, it would seem that Ball supplied Phoenix, Globe, Quarry, Beehive and Beaver exclusively and Bridge probably in part. Tingey supplied himself and Bridge, but these arrangements probably altered according to local animosity at the time. At various times, Ball cut off chalk supplies for a number of reasons that were more or less contrived with the object of demonstration his power; equally often, the manufacturers threatened to obtain chalk from up−river quarries unless Ball reduced his prices. Small wonder that the industry was in such a bad state at the end of the century.

Ball continued to quarry for A.P.C.M. (1900) Ltd. until November 1915, although production was very limited; in fact, production probably ceased for a while in 1909. He then tried to negotiate a new lease, but APCM decided to do their own quarrying.

In 1915, the leases of the derelict Phoenix, Globe and Bridge Works were renewed. Crown, which had recently been modernised, provided ample manufacturing capacity (due to the new rotary kiln installed in 1913) and, when a new quarrying lease was taken out, all the leases were due to expire on 29th September 1964. During the 1914-1918 War, the derelict works were demolished by the Navy and the rubble taken to block up the Zeebrugge Canal and Ostende Harbour. During the inter-War period, the area was finally tidied up, a second rotary kiln was installed, and the new works became known as Crown & Quarry.

On the outbreak of the 1939-1945 War, the works was taken over by the Ministry of Supply for the manufacture of fertilisers. On 11th October 1940, the leases of the Phoenix, Globe and Bridge areas were surrendered several years early, the sites subsequently being redeveloped. During the 1962-1963 winter, the quarry tunnel was extensively damaged by frost. This, coupled with the near-expiry of the leases, and competition from the Thames-side works, caused the quarry to be closed down on 5th March 1963*, the equipment being removed by June the same year. Finally, by mid-1964, the kilns and chimney had been demolished, and now it is planned to complete a modern industrial estate in the area.

* * *

Let us now turn to the railways that have operated in the area. The first would seem to have been short horse-worked tramways owned by John Cole by about 1863, at the quarries beside Phoenix Works, the horses being stabled in the quarry. The gauge of these railways may have been standard 4ft 8½in but was quite possibly of 3ft 6in. Certainly, both gauges were in use during later years and, from the later positions of the 3ft 6in tracks, perhaps the latter is more likely.

Another works in the area which, though not strictly connected with the Crown & Quarry group, should be described for completeness. This was Formby’s Whitewall Cement Works (closed 1909; auctioned 23rd July 1909) whose derelict site can still be examined; it never had a tramway and, after a 50ft deep overburden of Thanet Sand proved too much for quarrying, the works had chalk barged down from Halling. It was at this time that the proposal was put forward to extend Ball’s quarry lines to Whitewall, via the new tunnel.

* The quarry was officially closed on this date according to the Inspection Book, but chalk quarrying had in fact ceased in December 1962. The works closed for manufacture in 1963 after stocks of chalk had been used, but was staffed and locomotives worked there for several months until all cement had been despatched.

At the end of 1879, Cole was succeeded by William Ball, whom was a tenant on a year-by-year basis. He extended Cole’s tramway somewhat to serve the newly erected Globe Works and Bridge Works (reached by a tunnel carrying 3ft 6in gauge rails under Quarry Terrace Road constructed in 1885, the cost being paid by the Ecclesiastical Commissioners). Before long, however, he asked for security of tenure (by a long lease) so that he could extend and modernise his undertaking. The Ecclesiastical Commissioners refused permission for a number of years.

On 6th June 1884, it was suggested that Ball should drive a tunnel under Quarry Terrace Road, so that he could quarry on the eastern side of the hill and also to allow him to dump callow on the saltings, thus giving some value to otherwise useless land. The plan shows the tunnel to have been 700ft long and with an adverse 1 in 75 gradient to eastbound trains, dropping them at 1 in 200 down to the saltings. The railway was to be of standard gauge and it was proposed to connect it to Formby’s Whitewall Cement Works on Whitewall Creek; the plan also shows a line going off in the direction of the South Eastern Railway at Strood, though this is not marked specifically a such. Neither of these proposed lines was built, and the alignment of the tunnel and its length were also altered. By 20th July 1886, the tunnel was finished except for fencing and Ball was paid £1,575 for doing the job.

The tunnel immediately opened up new fields of supply for Ball. Within a few years, the standard gauge was extended south to serve the new quarry, Beehive and Beaver Works, while there was probably a transhipment point whereby chalk was tipped into the 3ft 6in gauge wagons (wooden side-tippers holding 55 cwts) serving Phoenix and Globe. Bridge, via its own tunnel, had 3ft 6in gauge quarry lines of its own.

Whether Ball was at this time using any locomotives is a doubtful point. Soon after completion of the tunnel in 1886, Ball asked for a long lease to enable increased expenditure on locomotives, wagons and tramways, while in June 1890, a review of Ball’s operations stated that he owned three or four steam engines, wagons, tramways, horses and buildings valued at £7,000. "As some factories are a long way from the quarries, locomotives are need on the tramways." Quite possibly these steam engines were stationary, for Aveling & Porter, the most likely suppliers of locomotives (as their works was nearby) have no record of deliveries at this time. (Two locomotives, of unknown gauge however, were delivered to I. Ball (Ball’s predecessor?), one in 1868 and the other (named BURNT OAK) in 1869. These were of six and ten nominal horsepower respectively, and were probably used on a coal wharf at Gillingham but may have been transferred to Frindsbury at a later date.)

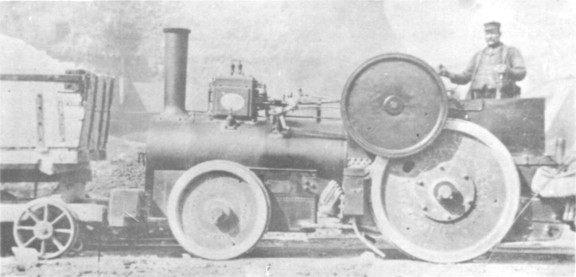

On 25th March 1892, Ball was finally granted a long lease. His first locomotive, named ALDERMAN, despatched from Aveling & Porter’s Rochester Works on 23rd October 1893 (works number 3277, type TC 10) was a standard gauge 10hp two cylinders compound 2−2−0 of the traction engine type; the cylinders were 7in (high pressure) and 11½in (low pressure) bore with a common stroke of 12in. SABINA, a larger 2−2−0 compound of 20hp and of type TCG, followed on 21st December 1898 (works number 4248); the cylinders were 9in and 14¼in by 14in. SABINA has been recorded as running on 3ft 6in gauge, but that dimension was in fact the boiler diameter; she was a standard gauge locomotive.

A plan dated 4th February 1891, shows the layout of the 3ft 6in gauge lines. One branch served Phoenix and another, running between Phoenix and Globe served the latter. Another line went off to serve Bridge. In 1894, the branch to Phoenix was probably abandoned and the line to Globe extended to serve both works.

After the APCM takeover in 1900, Ball seems to have continued quarrying much as usual, although there was not the same demand for chalk due to partial closure of some of the works. In 1905 he widened the tunnel to Bridge Works so as to take the standard gauge track from the eastern line. This was to meet APCM’s chalk requirements and cost £135/0/6. In this year, Williams took his son, Beckford, into partnership. It would seem that by 1905, therefore, the 3ft 6in gauge had ceased to be operative, except perhaps the lines to Cole’s and Phoenix Works’s piers. On 3rd December 1909, it was stated that no cement was being made, and this seems to have been the case for three years. APCM had taken to barging down chalk from Halling when any cement was to be made, and Ball’s quarries were inactive. In November 1915, Ball’s lease expired and APCM took over quarrying rights.

Before leaving this period, there is the question of William Tingey’s railways to be considered. He seems to have operated railways of unknown gauge on his own land for several years, these serving both himself and Bridge Works. On 29th August 1885, it would seem that Bridge Works was £12,500 in debt to Tingey and a document of this date contains the following passage. Bridge Works, when required by Tingey, "will find the necessary steam power for haulage, as at present, of chalk to the washmills." Bridge was paying Tingey ½d per ton for the first 150yds of chalk haulage and ¼d per ton for each 50yds thereafter. This is an almost positive reference to a locomotive – it is difficult to put any other interpretation on it – but details are not forthcoming.

LOCOMOTIVES AT CROWN & QUARRY CEMENT WORKS – 4ft 8½in GAUGE

|

Number |

Name |

Type |

Builder |

Number |

Year |

Source |

Disposal |

| 2-2-0TG | Aveling & Porter | 1524 | 1879 | (a) | s/s | ||

|

7 |

STUART | 0-4-0ST | Andrew Barclay | 681 | 1890 | (b) | (1) |

| LEOPARD | 0-4-0ST | Falcon | 239 | 1896 | (c) | Scr. 1930 | |

| KAPPA | 0-4-0ST | Chapman & Furneaux | 1164 | 1898 | (d) | (2) | |

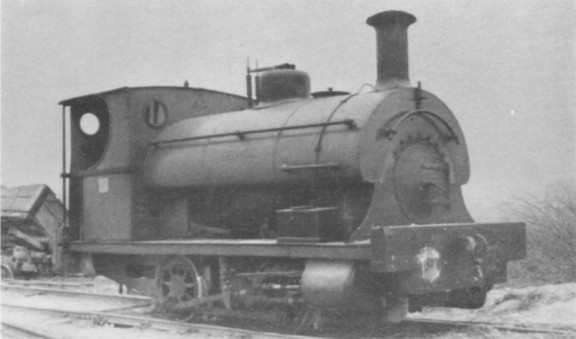

| GEORGE | 0-4-0ST | Peckett | 759 | 1899 | (e) | (3) | |

| J. G. B. | 0-4-0ST | Avonside | 1874 | 1921 | (f) | Scr. 8/1964 | |

| KILLARNEY | 0-6-0ST | Hudswell Clarke | 611 | 1902 | (g) | (4) | |

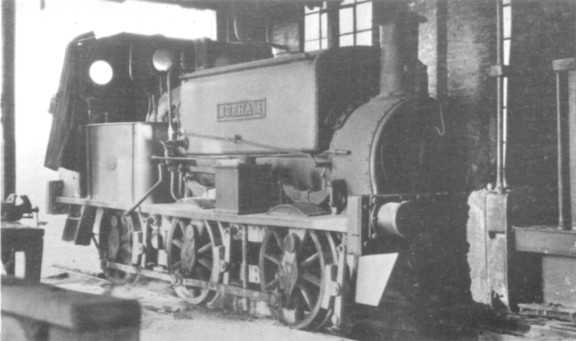

| BURHAM | 0-6-0ST | Manning Wardle | 730 | 1879 | (h) | Scr. 9/1952 | |

| C. F. S. | 0-4-0ST | Stephenson Hawthorns | 7742 | 1952 | New | (5) | |

| SOUTHFLEET | 0-4-0ST | Peckett | 1746 | 1928 | (j) | (6) | |

| STONE | 0-4-0ST | Peckett | 1740 | 1927 | (k) | (7) | |

| LONGFIELD | 0-4-0ST | Peckett | 1747 | 1928 | (m) | (8) |

| (a) | ex APCM Booth’s Works, Borstal, circa 1928 |

| (b) | ex APCM Brooks Works, Grays, Essex |

| (c) | ex BPCM Tolhurst’s Works, Northfleet |

| (d) | ex APCM Burham Works, Aylesford |

| (e) | ex APCM Bevan’s Works, Northfleet, 1934 |

| (f) | ex Thos. W. Ward Ltd., Grays, Essex |

| (g) | ex APCM Burham Works, Aylesford, 1934 |

| (h) | ex APCM Burham Works, Aylesford, 1947 |

| (j) | ex BPCM Johnson’s Branch, Greenhithe, August 1960 |

| (k) | ex BPCM Johnson’s Branch, Greenhithe, November 1962 |

| (m) | ex APCM Holborough Quarry, Snodland, 1962 |

| (1) | to BPCM Lee’s Works, Halling |

| (2) | to APCM Swanscombe Works, June 1931 |

| (3) | Scrapped by A. Arnold of Chatham, September 1960 |

| (4) | to APCM Burham Works, Aylesford 1934 |

| (5) | to Alpha cement Ltd., Shipton-on-Cherwell, Oxon, circa 1963 |

| (6) | to Thurrock Chalk & Whiting Co. Ltd., Essex, June 1964 |

| (7) | to APCM Holborough Works, Snodland, circa 1963 |

| (8) | to APCM Holborough Works, Snodland, 1962 |

LOCOMOTIVES OWNED BY WILLIAM BALL AT FRINDSBURY – 4ft 8½in GAUGE

| ALDERMAN | 2-2-0TG | Aveling & Porter | 3277 | 1893 | New | s/s | |

| SABINA | 2-2-0TG | Aveling & Porter | 4248 | 1898 | New | s/s |

ABBREVIATIONS USED IN THE LOCOMOTIVE LISTS

| Scr | - Scrapped | ST | - Saddle Tank locomotive |

| s/s | - Disposal unknown | TG | - Tank locomotive with geared drive |

However, to continue now with the railway of the APCM era. In November 1915 they possibly took over any locomotives Ball had at this time, and quarrying continued. The Quarry Terrace Road had been closed and quarried away in about 1909, and in due course, a connecting line was laid over Commissioner’s Road to the Southern Railway at Strood Dock, being brought into use on 26th January 1929. In anticipation of this, and increased quarrying (for the second rotary kiln was installed at Crown & Quarry at this time) several standard gauge locomotives were obtained secondhand. One of these was Aveling & Porter No.1524 (new to Booth Bros. at the nearby Borstal Works on 21st April 1879); it was a type T5 (5hp) 2−2−0 geared simple with 7in by 10in cylinders, 3ft 6in diameter leading wheels and 5ft driving wheels. Booth’s works closed in about 1928 and the locomotive was transferred then.

Quarrying continued apace until, by about 1942, all the usable chalk south of the Upnor Road and the footpath had been used. In this year some 75lb flat bottomed rail was supplied, probably for use on the branch to the new quarry north of the footpath. (The main line from the tip was slewed eastwards, somewhat on the course of the old Quarry Terrace Road, although many feet below its level.) This quarry was closed and a new one opened in 1954 north of the Upnor Road.

It might be convenient here to briefly describe the railway as it was in its final form. The chalk tip was south of the washmills, on the site of the old Beehive Works. The track ran on an embankment northwards to a junction; the western branch ran down over a weighbridge to serve the works. The other branch continued northwards past the locomotive shed. The latter, constructed in the 1930s, originally had two roads and was unusual in that it could be entered at either end but only on different roads. There was overhead lifting gear in the roof, and a watertank. At a later date, one road was disconnected, but there was still enough room for the duty locomotives to be stabled.

The track continued from here along the quarry floor to another junction. The quarry line went straight ahead, through a tunnel under Upnor Road, and into the 1954 quarry. The other branch ran westwards, across Commissioner’s Road, into a narrow tree-lined cutting, emerging at the other end at Strood Dock Sidings. One branch running from these sidings to the Atlas Stone Co. Ltd. formerly served Strood Canal Dock Cement Works, (opened 1866, closed about 1887) owned by Lark & White.

Quarry trains consisted of about ten wagons and two trips were made per day. Usually two locomotives were in steam, one on quarry traffic and the other working to the British railways sidings. Log-sheets were kept for every journey, a typical one being as follows:-

|

18th April 1957 |

|

|

left

chalk tip 10.30am |

left

chalk tip 3.00pm |

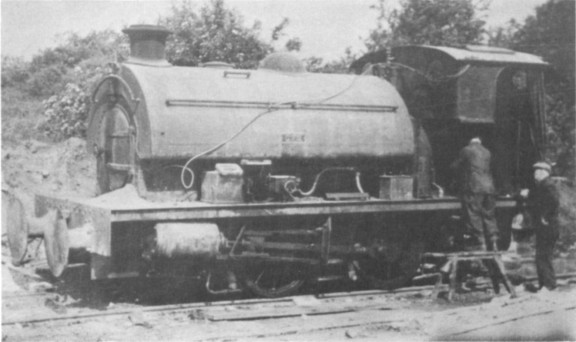

BURHAM, Manning Wardle 730 of 1879, in 1950. (F. Jones)

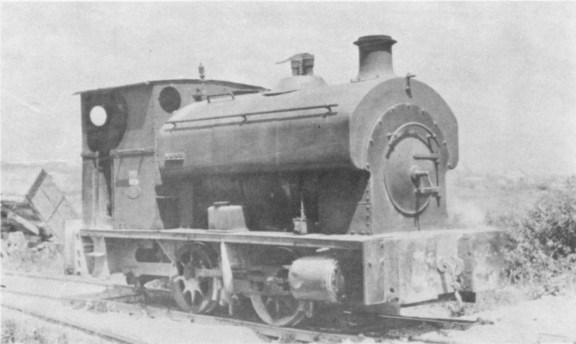

GEORGE, Peckett 759 of 1899 in April 1956. (Arthur G. Wells)

C.F.S. RSH 7742 of 1952 under repair, June 1963. (Author)

J.G.B. Avonside 1874 of 1921. (F. Jones)

As has been mentioned, Crown & Quarry Works was closed and tracklifting in the quarry began on 18th April 1963, the navvies being removed by 10th May. Some locomotives were still in use at this time, though, and there were four locomotives in all at the works. J.G.B. was partly dismantled in a shed near the bagging plant, and had been so for a number of months; officially it had been for repair, but this was never carried out. Of the others, STONE (see RECORD 3, page 45), was somewhat out of favour due to badly worn tyres. SOUTHFLEET, a sister of STONE except for not having a dropped footplate, was in regular use. C.F.S., he only new locomotive on the books, was also a regular worker.

By the summer of 1964, the only locomotive left was J.G.B. In August it was towed out of the shed and cut up. Tracklifting was begun in October, being carried out by two men who professed to be self-employed. By 2nd November, the track had been lifted as far as the level crossing, the rails being burned into short lengths and loaded into a small van. The only remaining piece of railway equipment (within the works, on track embedded in concrete) was a wagon frame and wheels loaded with a crane jib.

In due course, al traces of the works will be removed and the area redeveloped. As early as 1904, the Kent Electric Power Co. Ltd. leased part of the quarry floor adjacent to the footpath and on the land a generating station was constructed. On 3rd December 1909, it was stated that coal was being brought from Strood Sidings by traction engine haulage, to the detriment of the roads. It was not surprising that permission was soon obtained to lay a tramway along the road, to the Medway, in order to bring coal in by river. This doesn’t seem to have happened for the power station was closed a few years later. More recently, the sites of Phoenix, Globe and Bridge Works have been occupied by the London & Rochester Trading Co. Ltd., Medway Building Supplies Ltd., and the British Ceca Co. Ltd. and more factories have, or are being, put up.

The above photograph, loaned by Mr J. Faithfull, is reproduced by courtesy of The Cement Marketing Company Ltd. Whilst the locomotive was undoubtedly built by Aveling & Porter Ltd., the worksplate details are illegible on the original print and neither location nor locomotive have been identified. Frank Jones thinks it to be narrow gauge, and Aveling & Porter 1524 of 1879 at Booth Bros., Borstal cement Works, near Rochester (listed as 3ft 6in gauge) was considered a likely contender. However, this article gives 1524 as standard gauge. – Hon. Eds.

To conclude, it should be emphasised that this is in no way a complete account, particularly of the history of the works. There are large numbers of conflicting statements regarding who supplied who with chalk. Any information on any period of this history would be extremely welcome. I should very much like to thank the following who have generously offered help:-

E. Atkinson (Archivist, British railways Board); The Church Commissioners for England; T.W.B. Ellis (Aveling Barford Ltd); F.L. Parker (Cement Marketing Board); D. Stoyel; Arthur G. Wells; and the many APCM employees whose names are unknown to me.