| THE INDUSTRIAL RAILWAY RECORD |

© JUNE 1975 |

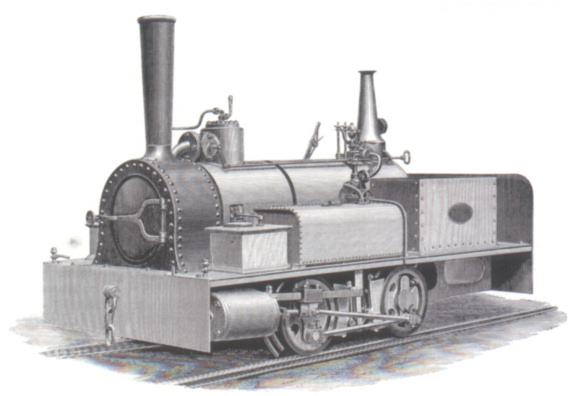

A NARROW GAUGE JOICEY LOCOMOTIVE

The above is 'a locomotive designed and manufactured by Messrs. J. and G. Joicey and Co., engineers, of Newcastle-on-Tyne, for the Mickley Coal Company of that city, for taking coals from their crushers over the top of their coke ovens for the purpose of charging them. The engine is of the four-wheeled outside cylinder coupled type, cylinders 4½in. diameter and 9in. stroke, the valve chests are inside the frames, and valves are worked in the usual manner. The frames are inside, run the full length of the engine, and are well stayed by cross transoms; the boiler barrel, outer fire-box, and front tube plate are made entirely of Low Moor iron; the inner fire-box of copper, tubes of brass; the gauge of the rails is 3ft. 6in.; the wheel base is 2ft. 9in. The wheels are of cast iron, with steel tires 20in. diameter on the tread. A constant feed is supplied to the boiler by a pump fixed to the front cross transom plate, and worked by an eccentric. This is supplemented, in case of accident to the pump, by one of Giffard's brass injectors. Side tanks are fitted to keep the weight as low as possible; and with a view to minimise the risk of damage to working parts, should the engine leave the rails - a not infrequent occurrence about colliery wagon ways - it is fitted with single motion bars; the advantage of this has already been several times demonstrated. The engine is fitted with a novel and powerful foot brake applied to all the wheels, which is simple and very satisfactory. Owing to the small size of the boiler, and the difficulty of getting inside to do any repairs to working parts, it was considered desirable to have the regulator valve outside, and, as will be seen, it has been fixed on the small dome at the front end of the boiler.

'The total length of the engine over all is 9ft.; extreme width, 5ft. 3in.; total weight in working trim, 3 tons. The work done by this engine was previously done by manual labour, which was very slow, and consequently costly. One man was able to charge fifteen ovens per day, at a cost of 4s. 2d., or £65 per year for wages. Since the engine was set to work it has charged ninety ovens per day, and thus does the work of six men, and with the greatest ease. The Mickley Coal Company is now completing its arrangements for fitting one hundred ovens of its very extensive range at Prudhoe to be charged by this engine, and so satisfied is it with the results given, that it intends to do all charging work by this means.'

("The Engineer," issue dated 8th December 1882, a copy of which has been kindly provided by Ralph Martin. Little information concerning the activities of J. & G. Joicey & Co seems to be available and we would welcome any snippets that readers are able to provide, particularly if related to their locomotive building (if any) and dealings. - TJL)