| THE INDUSTRIAL RAILWAY RECORD |

© FEBRUARY 1974 |

LEICESTER GAS WORKS

H.A. GAMBLE

Due to the increasing widespread use of natural (North Sea) gas in this country over the past few years, there has been a steady decline in the manufacture of traditional coal gas with the result that many of the gasworks, and the rail systems which often served them, have become redundant.

Leicester is no exception. Coal gas was first produced at Leicester in 1821 by the Leicester Gas Company, a private undertaking, at the Belgrave Gate works some three quarters of a mile north of the centre of the town. The site had been chosen because it was situated alongside the recently opened Leicester Canal; an extension of the Grand Union Canal, upon which coal was transported. Two gas holders were erected at the works and by 1822 the streets of Leicester were lit by gas lamps. A splendid, though by present-day standards unorthodox, feature of the Belgrave Gate works was the building of a brewery, in 1823, for the purpose of allowing shift workers two "beer breaks" per shift!

In 1832 the Leicester and Swannington Railway, engineered by Robert Stephenson, was opened for the express purpose of conveying coal from the Leicestershire coalfield to the town, thus effecting a considerable saving in transport costs. Unfortunately, the sidings and wharves were more than a mile from the gasworks and the coal had to be transferred by horse and cart in small loads which had an adverse effect on the cost of gas production. The L&SR was, in 1846, absorbed by the Midland Railway, and in 1849 a new connection was opened from Knighton Junction, on the MR main line, to Desford Junction, where it joined the former L&SR line to Coalville, and onwards to Burton-on-Trent. This branch in later years had a direct bearing on the gas industry in Leicester.

Two narrow boats, purchased by the gas company in 1867, were employed in coal carrying, but the absence of a direct rail link, and no doubt the lack of space for expansion in the town centre, forced the company to seek more land for an additional works. Eventually, in 1875, an ideal site of 32 acres was purchased, one and three quarter miles south-west of the town centre, which was bordered on one side by the MR Burton branch, on another side by the Grand Union Canal, and on the third by the main Leicester to Rugby road, now the A426. In addition there was plenty of adjacent land on which to expand if need be. The new Aylestone Road works commenced production in 1878 and was almost immediately bought by the Leicester Corporation.

Meanwhile Belgrave Gate works continued to produce gas efficiently in complement, and in 1882 the Great Northern Railway opened its branch from Grantham to Leicester with an imposing passenger terminus in Belgrave Road, only a stone's throw from the gas works, and with an extensive goods sidings in the vicinity. As luck would have it these were on the wrong side of the main road! Had this development taken place some forty years earlier it may well have been that the much needed rail connection could have been made, although the coal would have come, no doubt, from further afield than the local collieries. However, it was more convenient to transfer coal from the GNR sidings to Belgrave Gate works than from the MR wharves and eventually this was done by using Foden steam wagons hauling trailers. (A similar situation, involving short haul transfer of coal, obtained until quite recent years at Cambridge gasworks.) Belgrave Gate works continued to be modernised until it finally closed in March 1954.

Direct transportation of coal by rail was one of the factors involved in setting up the new works at Aylestone Road but the steam locomotive did not appear on the scene until 1885, the year in which the chemical works was being built. It is believed that wagon loads of coal had hitherto been moved by hand capstan to and from the horizontal retort house. ORION, the first locomotive, set a precedent for the subsequent fleet, all of which were four wheelers to enable them to negotiate sharp curves; likewise, all were named after celestial beings.

It is said that from the outset there was a standard locomotive livery which lasted throughout the administration of the Leicester Gas Department. The saddle tanks, boilers and cabs were painted maroon with a black lining picked out on both sides with yellow; the wheel spokes were yellow; the buffer beams and rods were painted red. Brass nameplates were affixed to the saddle tanks but no fleet numbers were carried. During, at least, its last fifteen years of life ORION was painted black "as it was little used", but it is not known whether it always wore this livery.

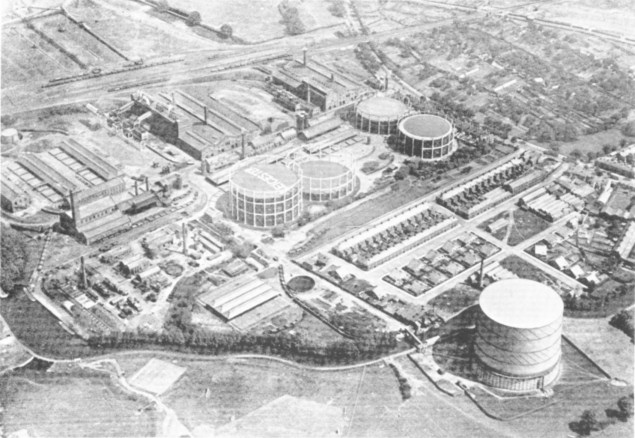

Aerial view of Aylestone Road works from the south-west, probably taken about 1931. (courtesy Emgas)

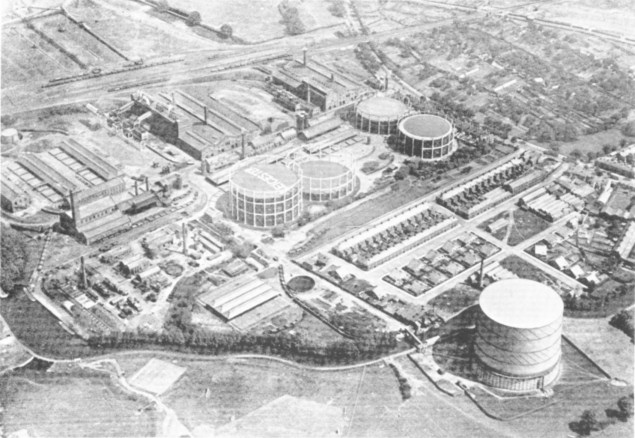

A view of No.2 retort house from the north-west, taken about 1900. Note the locomotive on the left, shunting a variety of wagons, mainly of Midland Railway origin. (courtesy Emgas)

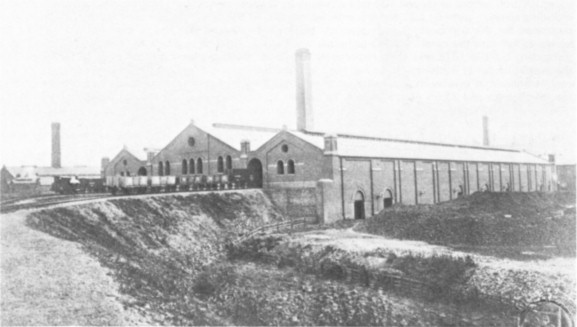

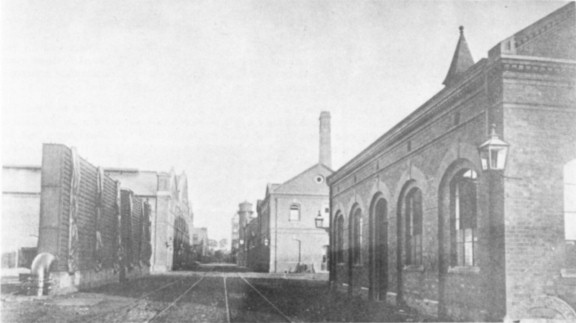

Main "Avenue" of Aylestone Road Works, looking towards the works entrance, about 1900. The locomotive shed is the nearest building on the right hand side. (courtesy Emgas)

The chemical works opened in 1886 and a second horizontal retort house was built in 1887, the year in which the rail system was completed. Extensions and alterations to the network took place in later years. By‑products, both from Aylestone Road and Belgrave Gate works, were now dealt with, amounting to some 100,000 gallons of tar and 100 tons of ammonia produced weekly. In addition twelve other products, including sulphur, carbolic acid and creosote, were made. At this time three horse drawn narrow boats were purchased for the transport of such products between the two works, and it was not unknown for the horses to fall into the canal! A third gasholder was built in 1888 to augment the existing No.1 and No.2 gasholders, built in 1878 and 1884 respectively. By 1891, when the second locomotive (SIRIUS) arrived, the output of gas at Aylestone Road had risen to seven million cubic feet per day, representing 700 tons of coal carbonised at maximum capacity. Out of every 100 units of coal carbonised the gasworks yielded 5% tar, 53.5% coke and 23.5% consumer gas. To give an increased yield it was found desirable to carbonise a mixture of small coals, which arrived by rail in quantities of 500 to 1,000 tons per day, according to requirements. These "smalls" originated from over twenty collieries situated in the Derbyshire and South Yorkshire coalfields, and while a list of these is too long to enumerate all are well known to photographers of industrial locomotives! The tonnage of coke distributed by rail, was in the order of 200 to 300 tons per day, much of which went to the London area, but some was exported to Scandinavia. Some 30 to 40 internal user rail wagons were employed about the works, and the Corporation owned a stud of 10 ton coal wagons for main line use. These were lettered "City of Leicester Gas Department" and, to the best of my knowledge, were painted black with white lettering shaded red.

Another element joined the scene in 1894 when an electricity generating plant was built, within the gasworks site, to supply the centre of the town. Rail connections were laid to the boiler house. The whole now came under the aegis of the Gas & Electric Lighting Committee. Generation of electricity ceased in 1928, after the new power station, on the opposite side of the Leicester to Burton branch, had been commissioned. (This will be fully described in a future issue of the RECORD.) The buildings were subsequently used to house high pressure gas compressors.

In 1899 a further new saddle tank (MARS) was added to the fleet, and in the same year a new relief gas holder for storing water gas was built. Further gas holders were constructed in 1902, 1930 and 1966, the latter on the site of the now demolished chemical works. Over the years the original horizontal retorts had given way to vertical retorts (incorporating the original buildings), the fourth and last section being opened in 1949.

In addition to the locomotive shed there was a fully equipped fitting shop which dealt with all repairs, including retubing and major overhauls. Four further steam locomotives were added to the fleet over a period of years. Two locos were in steam daily, one to shunt the sidings alongside the main line and the retort houses, while the other performed duties around the works and coke yards. Derailments to both locomotives and wagons were part of the routine but a more dangerous and spectacular happening took place during the late 1920's in thick fog. A train descending the bank from the sidings collided head on with another train charging up the bank. Although the wagons ended up all over the place and the two locomotives were derailed there was no serious damage to the locomotives or their crews! A steam crane from the main line company was called in to put matters right. It is thought that the locomotives concerned were MARS and JUPITER! Did this have any astrological significance, one wonders?

On 1st May 1949 the Leicester Gas Department was taken over by the nationalised East Midlands Gas Board at a time when the output of gas was approximately 4,000 million cubic feet per annum. In passing, it is believed that the highest output in one single day had been approximately 19 million cubic feet. No more steam locomotives were to be added to stock and on a visit to the works in 1953 it was found that MARS, JUPITER, and SIRIUS 2 were stored; ORION 2 was at work and MARS II was undergoing overhaul. All were still in the standard maroon livery. In 1957 the scene altered radically with the arrival of a new 0‑4‑0 diesel named MARS and painted blue. Tradition, except in the sequence of names, had been ruthlessly swept aside. The advent of the diesel led to the withdrawal of four of the remaining steam locos, and at this time one locomotive sufficed for the whole of the shunting duties. MARS II was retained as standby, seeing only occasional use when the diesel was under repair. The loco shed was demolished and both locos were then stabled in No.2 retort house. In 1964 MARS II was repainted in the new blue livery with a black lining picked out on both sides with white. The previously red buffer beams now displayed alternate black and yellow dazzle stripes. MARS, the new Ruston, was not to serve the works for as long as her steam predecessors for in July 1968 rail traffic ceased and on 1st August she was towed away by a BR diesel to the East Midlands Gas Board's Litchurch works at Derby, leaving a lonely MARS II to contemplate her fate. Herbert Lewin was the last driver to operate both MARS II and the Ruston.

Gas production ceased in May 1969, with the onset of natural gas, but the plant continued to be maintained for a further twelve months for use as standby if required. Demolition of the retort houses and the older gas holders commenced in the summer of 1972 but the site is still used, and will continue to be used, for compression of North Sea gas for onward transmission to surrounding districts, and as far away as Northampton.

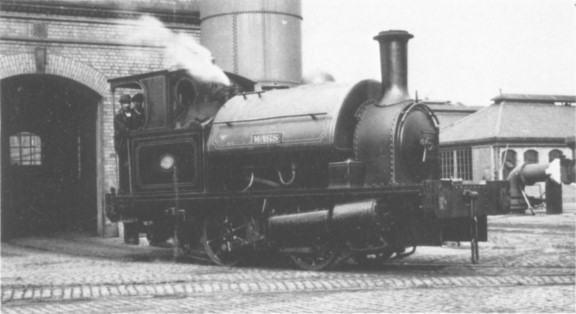

An immaculate MARS, obviously posed for the photographer. Note the dumb buffers and slide bar valances - as fitted to all the gasworks steam locos. 17th September 1951. (K. Cooper)

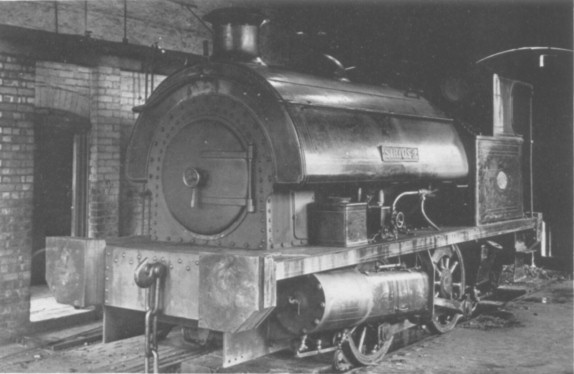

ORION 2, the last engine obtained by the works from Hawthorn Leslie & Co Ltd, seen here on 11th September 1955. (G. Alliez, courtesy B.D. Stoyel)

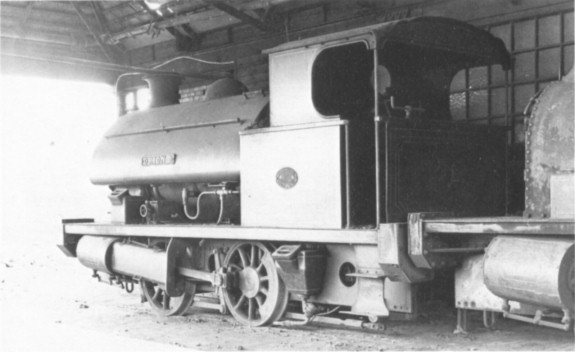

SIRIUS 2 at rest in the locomotive shed, 11th September 1955. (G. Alliez, courtesy B.D. Stoyel)

MARS II and SIRIUS 2 in the gasworks yard, 1956. Note the half back cabs, a feature probably common to all the steam fleet. (F. Jones)

MARS II shortly after being repainted in blue livery. 4th July 1964. (H.A. Gamble)

The locomotive stock, and its subsequent disposal, may be summarised thus:-

| ORION | 0-4-0ST | OC | R. & W. Hawthorn | 2027 of 1885 | (1) |

| SIRIUS | 0-4-0ST | OC | R. & W. Hawthorn | 2234 of 1891 | (2) |

| MARS | 0-4-0ST | OC | Hawthorn Leslie | 2411 of 1899 | (3) |

| JUPITER | 0-4-0ST | OC | Hawthorn Leslie | 2938 of 1912 | (4) |

| SIRIUS 2 | 0-4-0ST | OC | Hawthorn Leslie | 3588 of 1924 | (3) |

| ORION 2 | 0-4-0ST | OC | Hawthorn Leslie | 3802 of 1933 | (3) |

| MARS II | 0-4-0ST | OC | R. Stephenson & Hawthorns | 7493 of 1948 | (5) |

| MARS | 0-4-0D | Ruston & Hornsby | 414299 of 1957 | (6) |

(1) Scrapped 1937.

(2) Sold to John Lysaght Ltd, Bristol, 1936, via dealer C.D. Phillips, Newport.

(3) Scrapped by F. Berry, Leicester, 1958.

(4) Scrapped by F. Berry, Leicester, 1957. (5) Preserved 1968.

(6) To EMGB, Litchurch Works, Derby, 1968.

The story behind the preservation of MARS II is worthy of further comment. Following the cessation of rail traffic in 1968 she was left to stand forlorn in the works yard, and remained there for the next year and a half, although her fate had already been decreed. Shortly after her withdrawal someone in authority at Emgas had approached the President of the Leicester Railway Society enquiring if the Society would accept the locomotive for preservation. At the same time the Director of Leicester Museums was approaching someone else in authority at Emgas offering to preserve the locomotive! As everyone who has had a hand in the preservation of a locomotive knows, the whole exercise is fraught with difficulties, not least the acquisition of a suitable site to house the beast. As Leicester Museums already had a temporary (but full) railway museum, and a permanent one in course of planning, a compromise solution was evolved. MARS II would become one of the exhibits in the projected East Midlands Museum of Technology at Abbey Meadows, Leicester, and the LRS would be responsible for its restoration and maintenance. It was, at this stage, envisaged that MARS 11 would be a working exhibit on a short stretch of track. So far so good, but the Museum had nowhere to keep the locomotive as the building planned for the storage and restoration of exhibits had not then been commenced. MARS II was duly moved from the gasworks to Abbey Meadows on 2nd February 1970, where it once again stood out in the open gathering rust. The locomotive restoration shed was eventually built and in August 1972 the restorees gathered in. Owing to the unforeseen increase in the number of proposed exhibits, not only of railway but of all types of transport and machinery, there is little likelihood that space will be found to steam MARS I I when the permanent exhibition hall is completed. The Museum authorities are hopeful that a start will be made on the construction of this phase of the project in 1974 and to this end they were hoping to obtain enough enthusiast volunteers to commence work on the locomotives early in 1973. What ultimate livery MARS I I will appear in has yet to be discussed but it is good to know that one of the Leicester gasworks seven steam locomotives, spanning from 1885 to 1968, has been spared the breaker's torch.

In conclusion, I wish to thank the East Midlands Gas Board, also former employees H. Ellison and W.E. Gregory, for assistance in the preparation of this article.

'On the Leicester and Swannington railroad, there is a tunnel of about a mile long, on a part of the road which is nearly level; it is ventilated by eight shafts, and I have frequently passed through it with a locomotive engine. Even when shut up in a close carriage the annoyance is very great, and such as would never be tolerated on a line of road having a large intercourse in passengers. This railroad is chiefly used to take coals from some collieries near Swannington, and there is no intercourse in passengers upon it, except of the labouring classes from the adjacent villages: the engines burn coal, and not coke; and they consequently produce smoke, which is more disagreeable than the gases which result from the combustion of coke. This tunnel also is of small calibre.' ("The Steam Engine," by the Rev Dionysius Lardner, LLD, FRS, published by Taylor & Walton, London, 1836. - TJL)

Widnes Alkali Works. - 'On Monday about half past twelve some men were engaged at the above works in returning a locomotive engine to the lines from which it had slipped. In order to effect their purpose they had raised the engine from the springs with screw jacks and one of the men named Thomas Walsh was under the engine putting blocks in their places when by some means the jack slipped and Walsh was caught between the axles and strengthening plate on the engine. ... He is employed as a brakesman by Mr. Thos. Forshaw and has only been in that capacity about a month. He is injured in hip and chest but is progressing favourably.'

('Widnes Weekly News,' 1st June 1878. - JAP)

'Brunel outdone. - A scheme has been issued for a railroad to run from the Atlantic coast of America to the West. When the road reaches Lake Erie it is to be built out into the water about 25ft. below the surface for some distance, and there end. It is to be operated with a machine which will navigate the water as well as traverse the land. When this amphibious locomotive arrives at the jumping off place at Lake Erie it is to slide gracefully into the water and become a steam-boat, resuming its character of locomotive at Monroe. At Lake Michigan it is to take water again for Chicago. The inventor expects to attain a speed of 25 miles per hour on land and water.'

('Building' for 2nd June 1972, quoting 'The Builder' for 1st June 1872. - MJH)

"BUILDWAS POWER STATION. - The [Central] Electricity [Generating] Board's locomotives Nos. 1 and 2 with or without wagons attached are authorised to work over the following lines at Buildwas:- Severn Valley Lines between East and West Ends, and Much Wenlock line within the Advance Starting signals on each line.... Movements made with the Board's locomotive affecting the running lines or Buildwas Yard Sidings must in all cases be attended and piloted by the W.R. Operating Department Shunter."

(British Railways Western Operating Area Appendix to the No.14 Section of the Service Time Tables, dated May 1954. - BJB)