| THE INDUSTRIAL RAILWAY RECORD |

© FEBRUARY 1974 |

EXPLOSION AT SOUTH SHIELDS

'The locomotive is owned by Messrs. The Harton Coal Company, Limited, Whitburn Colliery, South Shields, ... [and] ... the boiler is of the ordinary locomotive type, and combined with the engine, is known as No.7.

'The boiler was made by Messrs. Chapman & Furneaux, Gateshead, but this firm is not now in existence. It was received at the colliery, when new, on the 29th December, 1898... In August, 1900, a set of new red metal tubes was fitted. The [143] tubes [were] expanded into the tube plates and fitted with iron ferrules at the firebox end. In March, 1903, a new copper firebox was fitted, the tubes being drawn to length and replaced in the boiler. In April, 1904, 61 tubes were taken out, the boiler cleaned, the tubes drawn one inch longer and replaced... In February, 1905, 90 tubes were taken out and the boiler cleaned, 58 drawn tubes were put in, and 32 old tubes replaced after having been cleaned and the ends softened... In November, 1905, the firebox was repaired, 11 copper studs being put into cracks, three roofing bolts renewed, and cracks on top of firebox caulked. In January, 1906, the locomotive was sent to the Forth Banks Works of Messrs. Hawthorn, Leslie & Co., Newcastle, for a new copper firebox to be fitted, and the old tubes drawn and replaced. These repairs were completed on the 26th April, 1906, [but] the locomotive did not, however, begin work at the colliery until June, 1906, and had, therefore, only been in use about six months after getting the new firebox [when the explosion occurred] . No further repairs were done to the boiler subsequent to April, 1906, until the 16th December, 1906, when the tube which failed was driven further through from the smokebox end, the ends expanded, and a ferrule driven in.

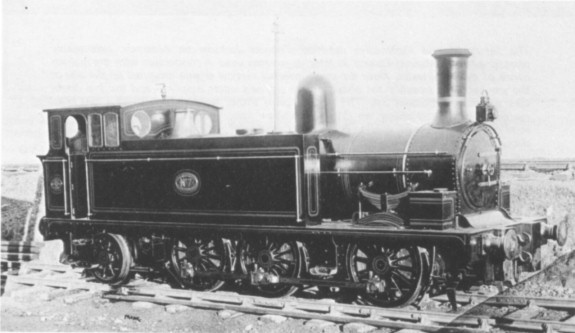

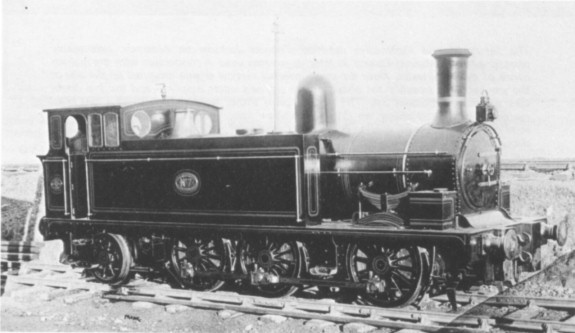

Harton Coal Company No.7 was Chapman & Furneaux 1158 of

1898, an impressive looking 0‑6‑2 side tank. The superb external condition

of the engine is clearly apparent from the illustration. Principal

dimensions were: 17in x 24in cylinders; 4ft 3in coupled wheels; 150 lbs per

sq in working pressure; weight, 45 tons 4 cwts.

(collection H. C. Casserley,

per F. Jones)

'The explosion occurred at about 5.0 p.m. on the 26th December, 1906, while the engine was on one of the sidings at Whitburn Colliery, South Shields... The locomotive was engaged in hauling trucks loaded with coal from the Whitburn Colliery to the Harton Coal Company's wharf at South Shields. It was in charge of the engine driver, Thomas Elliott, who stated that the locomotive had been running all day from 6.0 a.m., having made several journeys to South Shields, and it had just started on what would probably have been their last journey that day. At the time of the explosion the locomotive, with 15 loaded trucks attached, was on the siding close to the main line, and had just stopped for about five minutes until the main line to the coal wharf was clear. Immediately on restarting the engine, the tube failed with a loud report.

'The fireman, William Archer, who was about to fire had just fixed the fire door fully open, while the engine driver was standing with his hand on the regulator. On this locomotive double doors are provided on each side of the cab, as the line is laid in a very exposed place, i.e., on the cliffs overlooking the North Sea between Sunderland and South Shields. The men could, therefore, close both doors on the weather side of the cab, and thus secure some measure of protection in bad weather; but at the time of the explosion the weather was exceptionally stormy and the men had closed all the doors of the cab. This arrangement, coupled with the fact that the fire hole door was fixed fully open, undoubtedly led to the driver and fireman being scalded more severely than would have been the case if both doors on the lee side had been fully open. The pressure on the boiler is stated to have been 155 lbs. per square inch when the tube exploded, and the piece of tube (about 7/8 of an inch long) which had been in the fire box tube plate prior to the explosion was found at the bottom of the fire box amongst the ashes, with the ferrule still fast in it.

'The fracture took place at the inner side of the firebox tube plate, the tube being completely severed; the portion in the tube plate was blown out against the opposite side of the firebox, while the remaining portion dropped down about ¼ of an inch below the hole in the tube plate, and also appears to have sprung back from the tube plate about 1/8 of an inch; through the opening thus made the water was violently blown from the boiler, severely scalding both the engine driver and fireman.

'The explosion was caused by the tube having become so thinned round its lower half, at the inner edge of the tube hole in the firebox tube plate, that it was quite unable to resist the ordinary working pressure. The tube was reduced in thickness by the ferrule being unfairly driven into place, until it set up a cutting action and finally brought about the failure of the tube. ... The ferrule was made of iron and used just as it came from the hammer, excepting that it was rounded a little at the smaller end.

['It is now] proposed to true up the ferrules in the lathe before fitting them, and to use a drift when driving them into position, as there will then be more likelihood of their being driven straight than when using a hammer alone.'

(Information extracted from Boiler Explosion Report No. 1652, issued by the Board of Trade Surveyors' Office, North Shields. Although the incident relates to a relatively minor tube explosion it was, technically, a boiler explosion, and consequently a notifiable occurrence. The details recorded in the report of the repair work done on No. 7's boiler make interesting reading and it would appear the locomotive was an exceedingly hard worked machine, requiring a new set of tubes when but 20 months old, and a new copper firebox when just over four years old. It is remarkable that the replacement tubes of 1900, having been removed, cleaned and drawn, were re‑used in the two subsequent re‑boxings! The red metal tubes referred to were of a brass alloy which contained at least 80% copper rather than the usual 50% copper and 50% zinc.

Colin Mountford records in "The Bowes Railway" (published by the Society in 1966) that No.7 was the regular engine at Harton Staithes until the electrification of the South Shields, Marsden and Whitburn Colliery Railway, as the line from Whitburn Colliery to the Tyne was known. The locomotive passed to the Bowes Railway via the dealer R. Frazer in 1912 and seven years later further heavy work was done on the firebox; cracked frames and a worn cylinder resulted in the engine being fit only for scrap by late 1923. No. 7, although handsome, was not a particularly fortunate locomotive. - REW)

'SOUTH SHIELDS [, WHITBURN] & MARSDEN RY. - At the Whitburn Colliery shops of the Harton Coal Co., a complete armoured train has been fitted up for service on their line between South Shields & Marsden, which follows the coast quite close to the sea, near the mouth of the Tyne. The train comprises a four-wheeled tank engine, No.11, and several wagons. Even if the train should never be required for defence purposes, it is providing very valuable training for the men of the Territorial Forces now quartered in the district. The owners of the Colliery are to be congratulated on this practical form of patriotism.' ("The Locomotive Magazine," 15th October 1914. - KPP)