| THE INDUSTRIAL RAILWAY RECORD |

© APRIL 1973 |

GRIFF COLLIERIES

M. J. LEE

Nuneaton, a small town in North Warwickshire, was formerly known principally for its coalmining and associated industries. All the local pits have now ceased production, the last being Griff No.4 which was closed following the exhaustion of coal reserves. This was one of the pits on the Newdigate Estate worked by the Griff Colliery Co Ltd, of which Sir Francis Newdigate, one-time governor-general of Bermuda, was the driving force for many years. Until 1882 the Griff mines were operated under the direct control of the Newdigate family, but from the 12th September 1882 a limited liability company was incorporated to run the undertaking. This company - the Griff Colliery Co Ltd - continued in being until nationalisation of the coal industry came into effect on 1st January 1947.

The Newdigate family were quick to exploit the local coal deposits on their Estate. Development began in earnest during the early eighteenth century under Sir Richard Newdigate, who was responsible for two significant improvements. The more important was the adoption of Newcomens atmospheric engine to drain the mines, the first example being at work by 1716. The other improvement was the construction between 1700 and 1711 of three small canals or "boatways" (as they were known locally) to convey coal from the outlying parts of the coalfield. Undoubtedly the most famous person connected with the Griff mines was Sir Roger Newdigate (1719 - 1806), a leading advocate of canal transport and builder of the elaborate private canal system on the Arbury estate which incorporated portions of the earlier boatways. Sir Roger was to the canal age what Sir Arthur Heywood was to the railway era. During research into the history of the Arbury Canal it was found that railways had also been used in connection with the canal, three separate tramways being identified.

The first of these was built about 1773 to connect a number of small pits at Collycroft with a wharf at the head of the "Coventry Communication Canal" (Grid Reference SP356882). This line appears to have had a relatively short life, and was ultimately superseded by the six Collycroft locks which connected the 'Coventry Communication Canal" to the Arbury Lower Canal. The next tramway was built to convey coal from Griff to a wharf (SP354897) at the head of the Griff Arm of the Coventry Canal (opened on 29th July 1787) and was the precursor of the railway which carried coal down to these wharves until the coo of commercial traffic in 1961. The third tramway was built in 1793 from a wharf at the end of the New Cut (SP355887) to the pits at Griff. This was a double-tracked line which, in conjunction with that just mentioned, enabled Collycroft Locks to be bypassed in times of water shortage. Regrettably, no dimensions of any of these three early tramways have survived. Neither has their subsequent history, but it seems probable that the first and third mentioned became disused with the majority of the Arbury Canal system following Sir Roger Newdigate's death on 25th November 1806.

Little is known of the earlier pits operated by the Newdigate family. Barbara Shaft had been sunk well before 1831 and was deepened in 1831-33: the neighbouring Caroline Shaft was sunk in 1832-33. Griff No.4, already mentioned, was sunk in 1850-51 and was followed some twenty years later (1870) by No.5 pit. The Clara and Marion shafts were sunk in 1894-95 and it is recorded that this undertaking, known as Griff Clara pit, was in full production by 1897, being the first pit in the Warwickshire Coalfield to raise 1,000 tons of coal in a day. Indeed, by 1902 the annual output of the Griff collieries had reached half a million tons! Early shaft closures are not well documented. According to local records Griff No.5 closed about 1900. Griff No.4 Charles shaft, mentioned in a 1929 catalogue listing abandoned mines, was a shallow upcast return airway shaft that was never used for coal winding: it also served as an emergency man-winding shaft. The steam winding engine which worked this shaft was a conversion from an old agricultural steam ploughing engine, and an old timer I spoke to about this shaft still retains vivid memories of this rather unconventional winding gear'.

Some confusion surrounds the history of what may have been the oldest locomotive at Griff. Society records show it to be CREWE, an inside cylinder 0-4-2 saddle tank built by Bury, Courts & Kennedy in the 1840's, which is thought to have been obtained from the LNWR in 1871. It eventually passed to the Shropshire & Montgomeryshire Railway in 1911 (per R. Hartley) and a photograph of the engine running on the S&M as SEVERN appears on page 62 of Eric Tonks' recently republished book "The Shropshire & Montgomeryshire Railway". However, in "The Locomotives of the Great Western Railway" (RCTS), SEVERN is stated to have come from the Bristol Port Railway & Pier where she was an 0-4-2 side tank, their No.2. Originally built as an 0-4-2 tender engine by the St Helens Railway in the 1850's for their own use, it was taken over by the LNWR and later disposed of: J. Cross & Co rebuilt it to a side tank and it then passed to the BP&P.

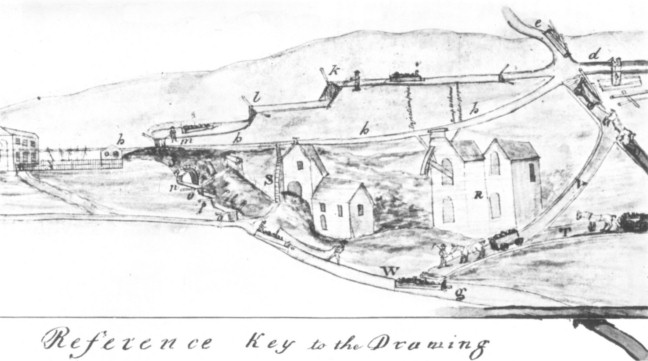

A map of the tramroad and canal system at Griff about 1805. The dotted (lifted) tramroad is that which was discontinued following the installation of Collycroft locks. That built in 7787 runs on a straight course from the "Coal Pits" to Griff Hollows Wharf on the Griff Arm of the Coventry Canal. The final tramroad (1793) extended from the New Wharf, situated on Griff Lane, to the Griff Hollows Wharf, running via the "Coal Pits". Based on map CR 136/758 from the Newdigate Archives currently on loan to the Warwickshire County Council.

| d e g hh klmnopq R S T V W |

Canal to the New Wharf |

A contemporary artist's impression of the Griff tramroad wharf on the cut from the Coventry Canal to the Arbury Canal. Collycroft locks, which eventually superseded this tramroad system, are also visible. From drawing CR 136/M76A-76C of the Newdigate Archives, at present on loan to the County Record Office at Shire Hall, Warwick, of the Warwickshire County Council. |

SWALLOW, the next known arrival, was an outside cylinder 0-4-0 saddle tank built by Black Hawthorn in 1873 (works number 174), and was obtained from C. D. Phillips of Newport, in 1882. It was subsequently rebuilt by W. G. Bagnall in 1894 and eventually passed (in December 1901) to Nevill Druce & Co, Llanelly, per Williams, Cornforth & Co, the Kidsgrove dealers. A fascinating contemporary description of this ill-fated locomotive appears elsewhere in this issue.

Five inside cylinder Sharp Stewart 0-6-0 saddle tanks are known to have been used on the Manchester Ship Canal construction and one of them, KNUTSFORD (Sharp Stewart 3471 of 1888); was obtained by the Griff Colliery Co Ltd, presumably directly from the Ship Canal contract although the date of 'transfer' is not recorded. (A sister engine, NORTHWICH (Sharp Stewart 3473 of 1888), was illustrated on page 57 of RECORD 2.) Virtually nothing of the history of KNUTSFORD while at Griff is known: she passed eventually to the Broughton & Plas Power Coal Co Ltd, near Wrexham, at an unknown date.

The first new locomotive to arrive at Griff was GOOD LUCK (Hunslet 498 of 1890), an inside cylinder 0-6-0 saddle tank with 13in by 18in cylinders and 3ft 1in diameter wheels. Its original livery was Victoria green, picked out with a 5/8in gold band edged with vermilion on the inside only, the distance line being Naples yellow; the frames were brown and the loco had a in dark green 'style' with a gold stripe on the panels only. A 'style' is an upright member in framing or panelling and is thought here to refer to a 3in band round the edges of the cab side sheets, and possibly the saddle tank sides also. GOOD LUCK was ex-works on 14th November 1890 and to some extent the name was synonymous with the locomotive's own fortunes for it was destined to have a lengthy stay at Griff, remaining one of the 'regulars' for over seventy years!

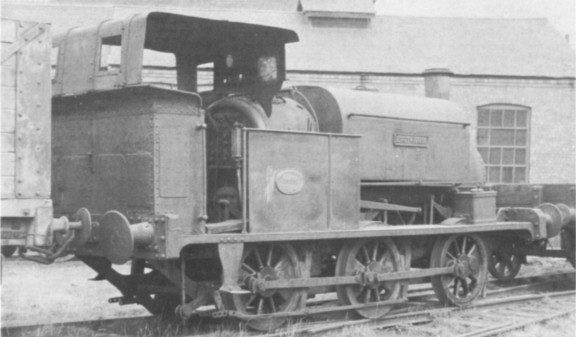

GOOD LUCK (Hunslet 498 of 1890) at Clara pit on 30th March 1956, complete with original pattern smokebox door. (M.J. Lee)

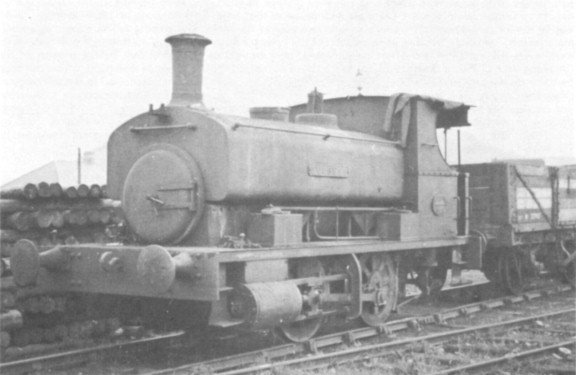

BRITANNIA (Hunslet 222 of 1879) at Griff Sidings, on the ex LNWR branch on 19th September 1955. Compared to GOOD LUCK, this locomotive has brakes on the middle and rear axles only. (M. J. Lee)

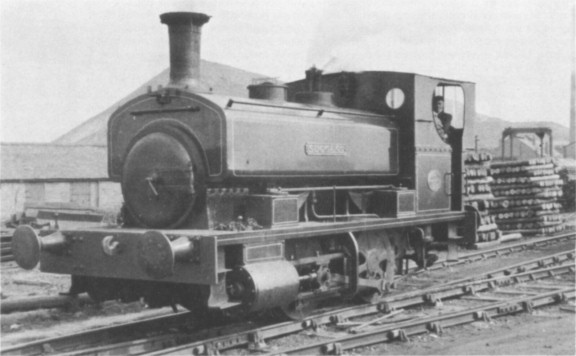

The very flimsy nature of the cab sheet on BRITANNIA is plainly visible on this photograph taken at Clara pit on 30th March 1956. (M.J. Lee)

BRITANNIA, obtained third-hand for £450 in June 1894 from the Alexandra (Newport & South Wales) Docks & Railway at Newport, appears to have been the next arrival. Another inside cylinder 0-6-0 saddle tank (Hunslet 222 of 1879), she was supplied new to Beckett & Bentley for a contract at Rochdale. BRITANNIA was similar to GOOD LUCK in several respects and perhaps some degree of fleet standardisation was obtained as a result of her purchase, although this was probably more by coincidence than forethought!

A note in the old Minute Books records that in 1896 a "Saddle-Back" locomotive was purchased for £400. From available evidence it seems likely that this refers to the acquisition of an inside cylinder 0-6-0 saddle tank from J.S. Jackson, a contractor at Cardiff. Built by Manning Wardle (1102 of 1889), this class M loco was originally supplied to T.A. Walker for his Manchester Ship Canal contract, where it bore the name PRESTWICH. Manning Wardle records show that it was later with J. Strachan on a contract at Cardiff. At Griff it was called BOBS and was another enduring servant.

BOBS, BRITANNIA and GOOD LUCK, together with SUCCESS - an outside cylinder 0-4-0 saddle tank obtained new from Andrew Barclay (1167 of 1909) - were to remain the mainstay of motive power at Griff until nationalisation. Also, with the exception of BOBS - which did not see much service under the auspices of the National Coal Board - they formed the nucleus of the locomotive fleet at the Griff collieries after 1947, for the NCB did not see fit to introduce many new locomotives or transfer the older ones elsewhere. The arrival of SUCCESS no doubt caused much eye-opening amongst the engine men at Griff, for she was fitted with the steam brake. BOBS, BRITANNIA and GOOD LUCK had only a hand brake and it is pretty certain (from information handed down) that all the earlier engines had hand brakes only. It was almost as if SUCCESS set the standard - for all later engines which were destined to work at Griff had the luxury of steam braking!

Griff Clara (No.1 and No.2 pits) and Griff No.4 were regarded as separate units even before the advent of the NCB, each having its own manager. This was certainly the case in the 1920's, when requirements were such that Clara employed some 1,100 underground workers with 250 on the surface; the totals for Griff No.4 were 850 and 150. No.4 pit was extensively rebuilt and brought up to modern standards in the late 1930's. The old steam winding engines were replaced with new electric units, an entirely new shaft was sunk, new screens were erected and the pit was extensively electrified. By the close of 1938 the pit was regarded as one of the most modern in the country. Without doubt it was the Griff Colliery Company's "showpiece".

Before Nationalisation it was the practice to keep one loco at No.4 pit and for many years this was usually BRITANNIA. The other locomotives - GOOD LUCK, BOBS and SUCCESS - were all regular performers at Clara pit, although there doesn't seem to have been a particular favourite here. During this period the engines were very well kept with gleaming paintwork and highly polished brass and copper work. The Company's standard loco livery was unlined black with red motion work and buffer beams, and at the time of Nationalisation BRITANNIA, BOBS and GOOD LUCK were all in this livery. As far as is known SUCCESS was never repainted prior to Nationalisation: she retained her maker's standard dark green livery. Being a short wheelbase engine, SUCCESS was much favoured for shunting duties at Griff Basin canal wharf, and was also a handy machine for negotiating the short steeply graded line up to the boilers at the pumping shafts. These were the old Caroline and Barbara shafts, where two ancient beam pumping engines of the atmospheric type were located. With 60in by 96in cylinders supplied with steam at 10 lb/sq in and with a capacity of five strokes a minute, they were able to pump 24,000 gallons of water an hour. Both were erected in 1833-34, and one of them continued to operate until replaced in the early 1950's by electric pumps.

Since both pits had their own loco allocation a shed was provided at each to house the motive power. The shed at Clara pit was a single road building (Grid Reference SP348889) of mainly wood construction capable of holding two six-wheel tanks. That at No.4 was a single road brick building adjacent to the colliery screens (SP349905) and was capable of holding one loco. At the far end of this shed the track extended through doors into the fitting shop where both No.4 and Clara locomotives were repaired. Soon after the Second World War commenced a new brick-built engine shed (capacity one loco) was erected on land near the Caroline and Barbara shafts, about halfway between the canal basin and Stanley Bros Ltd No.5 Brickyard. Known as Bermuda shed (SP352897), it was a "run-through" type with doors at both ends. Occasionally the working locomotive from Clara pit used Bermuda shed during the war period but more often than not there would just be a serviceable spare engine kept here. The idea behind this was that the loco was far less likely to suffer from any air-raid damage since the shed was well away from the main collieries. With the cessation of hostilities this shed was not used and became derelict a few years later.

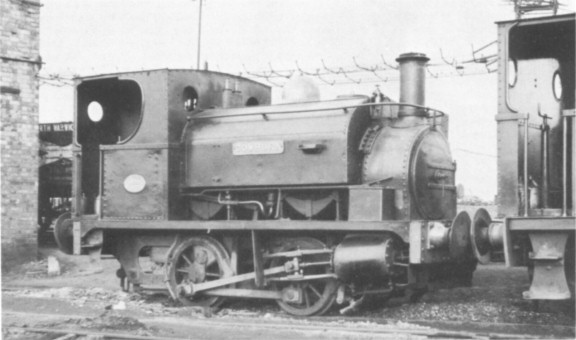

SUCCESS at Griff No.4 pit on 9th June 1952, before rebuilding. Compare the cab in this view with that fitted after overhaul. (M.J. Lee)

Some loop lines to the south of Bermuda shed were used in connection with coal stocking activities in an area referred to as "The Field". They also formed a useful route for the Clara loco to gain access to the canal basin and the pumping shaft siding without using the ex LNWR line via Bermuda Road level crossing.

Towards the end of the Second World War BOBS was somewhat run down and did little further work. It did pass into NCB ownership but was eventually scrapped in April 1948. During the latter part of 1947 several of the Griff engines were giving trouble and needed urgent repairs. As a result an engine was obtained at short notice on loan from Pooley Hall Colliery in January 1948. This was COWBURN, an outside cylinder 0-4-0 saddle tank built by Hunslet (544 of 1891). COWBURN saw service mainly at No.4 pit, being at Griff some 18 months until it returned to Pooley Hall in June 1949. Livery was unlined black with red motion work and buffer beams.

Just before BOBS was scrapped an ex WD "Austerity" locomotive was purchased in March 1948 and put to work at Clara pit still in WD livery. A standard inside cylinder 0-6-0 saddle tank (Hunslet 2859 of 1943), it carried the WD number 75010, being one of a batch ordered by the Ministry of Supply in July 1942. While the power of this engine was very much appreciated, its weight - 48 tons in working order - was not! Much of the Griff track was laid with rather light rail which did not stand up too well to the weight of 75010, so it only had a short sojourn at Griff, being despatched to nearby Baddesley Colliery in August 1948.

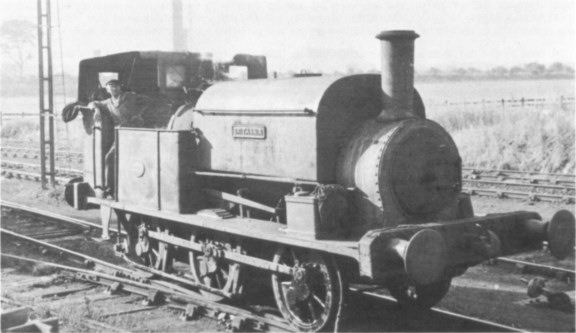

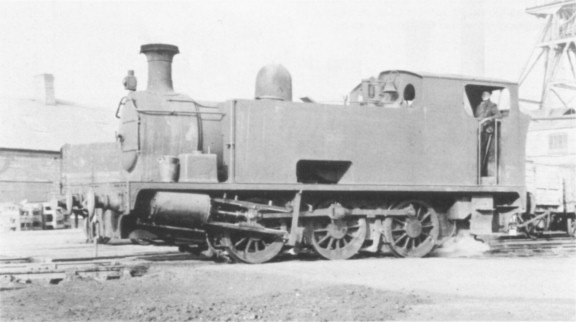

In 1948 a further ex WD engine was purchased, presumably to replace 75010. This was WD 70211, an 0-6-0 side tank with outside cylinders, built by Hudswell Clarke in 1915 (works number 1102) to their well known "PLA" design. In fact this particular loco had formerly worked at the Port of London Authority as PLA No.46 before being requisitioned by the War Department. The weight of this machine in working order was 42 tons, only a little short of that of 75010, yet during its service at Griff it gave surprisingly little derailment trouble. It was very popular at Griff, and soon became a firm favourite with old Harry Cooper, who was the Clara pit loco driver at that time. By the spring of 1954 however, 70211 was in a very run down state, and a general overhaul at the maker's was being talked about. This never materialised - possibly because an inspection of the tyres by British Railways' staff in that year forbade its moving via BR metals - and after the summer it only worked on odd occasions. By the summer of the following year (1955) a quantity of spares had been purchased for the repair of the engine which had been partially dismantled by September 1956, moves having been made to get it overhauled in the workshop at Coventry Colliery. This came to nothing as the BR authorities again refused to let the loco on to the main line because the tyres had worn too thin. It could have gone away by road, of course, but instead lingered on in a derelict state for some years, being eventually broken up at Clara pit about September 1960 by John Cashmore Ltd of Great Bridge. Throughout its whole career at Griff Clara the locomotive retained its WD livery: it was never allocated to No.4 pit.

After about 1950 BRITANNIA did not do a great deal of work and was more or less relegated to standby status until finally withdrawn from service at the close of 1955, still in Griff Colliery Co livery. By March of the following year she was dumped in the open at the back of Clara pit, and scrapping on site (by J. & H.B. Jackson Ltd of Coventry) followed in September 1956. Until sometime after the end of the war the engine sported a highly polished brass 'trumpet' safety valve casing which had always been a distinctive feature. BRITANNIA showed signs of having been rebuilt in later years, possibly in the early 1930's, as the saddle tank which she carried latterly was obviously a replacement and of a more square design than the usual Hunslet pattern. Also, the cast chimney carried in later years was definitely not of Hunslet design. It is known that the loco had been rebuilt with a Bagnall boiler at an unknown date.

By the summer of 1952 the boiler of GOOD LUCK had been condemned, and a new replacement one had been obtained from Hunslet, this arriving at Clara pit. The work of rebuilding this engine was subsequently contracted out to a private concern, S. Briggs of Burton-on-Trent, a decision which caused more than a little upset with the Griff maintenance staff. However, their protests were to no avail, the engine being sent away during August 1952. GOOD LUCK returned to Griff No.4 on 9th July 1953 and was in primer paint only, as apparently the contract did not specify a full repaint. The engine was subsequently repainted in NCB blue and lined out in the fitting shop, being steamed at No.4 pit on 13th November 1953 for the first time after being rebuilt. She remained at Griff until September 1962, when transfer to Haunchwood Colliery took place. Considered to be too small for the work here, she was never steamed and for a lengthy period lay dumped at the top of the pit yard before being scrapped in June 1966.

SUCCESS went to No.4 pit on a regular basis during 1950, and became due for a general overhaul by the end of 1953. This work was put in hand once GOOD LUCK was working satisfactorily, and included a complete retubing of the boiler, the fitting of a new saddle tank and a new right-hand cylinder (since the old one was cracked), a complete overhaul of the motion, and re-tyring of the wheels. The cab was also somewhat altered for the driver's comfort, an extension being built on to the cab rear and its roof. A back-plate made of Perspex corrugated sheets fitted at the same time gave the engine quite a novel appearance. Fully repainted and lined out in NCB livery, she commenced working again at No.4 pit on 26th March 1954, remaining in regular use there until the spring of 1958, when the boiler was condemned. However, a new one had been obtained from Andrew Barclay's together with a new tall chimney. These were fitted and the engine put to work, again at No.4 pit, by 21st June 1958. She remained there until 21st December 1960, when she was sent to Haunchwood Colliery. SUCCESS was never popular there, and did not see a great deal of use. Along period was spent dumped in the open in the company of GOOD LUCK, until both were scrapped in June 1966 by John Cashmore Ltd of Great Bridge.

After 1950 few transfers between the two pits took place. During her remaining time at Griff SUCCESS was to stay at No.4 pit. Similarly, BRITANNIA stayed at Clara pit on a regular basis. The only loco which did move frequently between the two was GOOD LUCK. She was normally to be seen at Clara but stood in at No.4 pit on the occasions when SUCCESS was not available. Such substitutions are known to have taken place in 1954, 1955 and 1956. GOOD LUCK was noted under repair at No.4 pit in December 1960 and was still in store here nearly a year later, well before her transfer away from the system. In the early 1950's GOOD LUCK, SUCCESS and 70211 were running with "chip-pan" type spark arresters but after these rusted away they were not renewed.

Two views of SUCCESS (Barclay 1167 of 1909) at No.4 pit on 16th April 1954, newly overhauled. Points to note are the cab extension and the Perspex back plate. The whistle has also been repositioned, possibly in conjunction with the cab modifications. (M. J. Lee)

COWBURN had a short spell at tariff when loaned in 1948 due to a motive power shortage. Seen here on 1st March 1959 at its more usual haunt, North. Warwickshire Colliery, the NCB's new name for Pooley Hall Colliery. (K. M. Buckle)

Hudswell Clarke 1102 of 1915 at Griff in 1953. WP D 70211 is barely discernible on the side tank. The spark arrester was fitted sometime after June 1952. (F. Jones)

Most of the work at Griff consisted of taking coal away from both Clara and No.4 pits via the single line BR (ex LNWR) Griff Branch to Griff Junction on the main line between Coventry and Nuneaton. Needless to say, all the Griff locomotives were authorised to run over the ex LNWR metals between the two pits. One loco was in steam daily at each pit, with Clara working on a one shift basis from 7.00 am to some time between 4.00 pm and 4.30 pm. On the occasions when Saturdays were worked the finish was 11.30 am. At No.4 pit work was such that two shifts were needed, namely from 6.00 am to 2.00 pm and 2.00 pm to 10.00 pm. This was the case for many years until about 1950 when a single long day turn was introduced (6.30 am to 4.00 pm): again the shift finish was 11.30 am on the Saturdays that were worked. Each loco worked with a crew of three - a driver and two shunters. A night shift loco cleaner was employed at each pit to attend to the lighting up and preparing of the loco in readiness for when the crews came in the early morning.

The Clara engine, in addition to serving the pit, worked traffic (usually two trains daily) from the pit to the canal basin. When required it also took traffic from No.4 pit destined for the canal - this was collected from Griff Sidings and then worked down to the basin. On the intermittent occasions when the Griff pumping shaft was working - for example during times of heavy rainfall - the Clara engine took coal traffic two or three times weekly up the steep incline to the siding which served the pumping shaft boilers. As if this were not enough it also worked coal traffic into the nearby Stanley Bros Ltd No.5 Brickyard and the Haunchwood Brick & Tile Co Ltd No.3 Brickyard two or three times per week! BRITANNIA and GOOD LUCK were the last two engines to perform these duties from Clara.

The No.4 engine was also given plenty of work to occupy its time. Apart from shunting the pit yard and sidings it served the Haunchwood Brick & Tile Co Ltd No.2 Brickyard, which included the brick loading bank on the pit yard side of Heath End Road. The line to this brickyard was extended in the 1950's for access to a new tip in the works old claypit which lay between Heath End Road and Croft Road. Wagons of 'clod' (the local term for colliery waste) were then taken by the No.4 engine via the level crossing connection over Heath End Road and this traffic eventually built up to about 30 wagons per day. Wagons were not plentiful in supply and very often BR wagons were pressed into service on this duty. The actual tipping was a somewhat hazardous operation as the wagons were propelled to the very edge of the tip, and sometimes the track gave way. It was not uncommon for wagons to plunge into some 60 feet of water never to be recovered, and several BR wagons which entered No.4 pit sidings were "lost" without trace in this way! There were also several scares with the locos on occasions, and I recall a very near miss that SUCCESS experienced on the tip.

In NCB days the internal traffic on the system between the two pits, the canal basin and the various brickyards was dealt with in some 350 wagons. These were mainly old "Private Owner" wagons of the 10-ton and 12-ton variety: they had wooden bodies and most still had "fat" axleboxes. In addition some half-a-dozen flat wagons were employed for carrying stores and oddities such as locomotive boilers. The Colliery Company had owned a large fleet of 10-ton and 12-ton wagons which were allowed out over the main line railways. If my memory serves me correctly these were painted black with the word GRIFF displayed on them in large white letters. When tipping in the disused claypit at the Haunchwood Brick & Tile Co Ltd No.2 Brickyard started in NCB days about a dozen special hopper wagons with side tipping doors were brought in for this purpose but these were not a great success: this was mainly because the operating gear on the doors was easily damaged with the rough usage experienced on the tip. More often than not ordinary internals (and BR wagons) were preferred for the job.

A description of the working of the ex LNWR Griff Branch may be of interest. Officially opened for traffic on 22nd June 1881 it had a long and interesting history. The Midland Railway, for example, could claim running powers over the branch and their locomotives commenced working in this manner on 11th September 1889 by a reciprocal arrangement whereby the LNWR - from the same date - were authorised to work over the MR Stockingford - Ansley Hall Colliery Branch. Access to the Griff Branch was controlled by Griff Junction signal box, and from here to Bermuda Level Crossing ground frame (½ mile) the branch was double track with an "up" and a "down" road. From the level crossing at Bermuda the Griff Branch proper became single track and continued on a rising gradient until Stanley's Sidings were reached. A trailing connection serving the basin at the head of the Griff Arm of the Coventry Canal left the branch immediately past the Bermuda crossing, and about 150 yards further on the branch serving Clara pit and Stanley Bros Ltd No.5 Brickyard diverged to the left. This short branch was known officially as Griff New Colliery Branch. Griff Sidings were adjacent to the Haunchwood Brick & Tile Co Ltd No.3 Brickyard at Bermuda. These were used for making up the trains which were despatched from the branch. Further sidings diverged from this point to serve the brickyard and No.4 pit. The BR branch foreman had his cabin at Griff Sidings and kept here the "staff" used in connection with the single line working to Stanley's Sidings at Stockingford. The Bermuda level crossing ground frame controlled access to the Griff New Colliery Branch, the siding to the canal basin and the access to the double track section which led to Griff Junction. This latter section boasted an "S" bend of rather severe curvature and BR drivers waiting to leave the branch with a fully loaded train (a maximum of fifty wagons) for the Coventry direction preferred to wait back at Bermuda crossing until they received the "right-away" from Griff Junction box. This was to enable them to take a run at the "S" bend "flat out", and by the time the train was passing over on to the "up" main line the permitted maximum speed for the branch (10mph) was often exceeded! The locomotives of trains bound for the Nuneaton direction propelled their stock off the branch "wrong road" on to the "down" main line at Griff Junction before setting forward for Nuneaton.

For many years the "main line" trip work on the branch was performed by engines and men from the motive power depots at Nuneaton and Coventry. The loco provided was appropriately an ex LNWR 0-8-0 tender engine but in later years it was by no means uncommon to find an ex LMS "Jubilee" or "Patriot" at work on the branch! Stanier "Black Fives" and 2-8-0's together with Hughes 2-6-0 "Crabs" and Ivatt "Moguls"' were all regular visitors. Until shortly after the end of the Second World War "Block" coal trains were run from Griff to such destinations as Oxford, Wellingborough and Willesden (London), but with changed methods of working in the post-war period the only "Block" trains were occasional "specials" to Hams Hall and Nechells Power Stations. In this latter phase the traffic from the Griff Branch was then worked into the BR yards at either Hawkesbury Lane or Nuneaton, for re-marshalling. By the early 1950's the Griff pits were probably turning coal at a rate never previously reached in their history so it is not surprising that up to five trips per day (130-150 wagons total) were taken away - three to Hawkesbury Lane and two (usually) to Nuneaton. Coal empties were received daily from Willesden, also several private sidings - Foleshill Gasworks, Longford Power Station and Webster's Sidings to name a few. After bringing empties on to the Griff Branch the BR engine ran round its train and then banked it into either the No.4 sidings or the Clara sidings, as required. To push some 50 or 60 empties up the sidings at No.4 was not an easy task as the line was steeply graded up to the pit from the level crossing at Bermuda village and under bad conditions much slipping and sliding would result! Obviously the converse was true for getting wagons to run out of the No.4 sidings by gravity. In fact they sometimes moved far too easily if the brakes were a little defective and on more than one occasion a "runner" (as they were termed) ended its career by being derailed in the loop catch points! To bank empties into Clara sidings was a much easier operation for the BR engine as this line was not so steeply graded as the other. The main line engines were not allowed to enter any sidings on "The Field", nor those around the canal basin and the pumping shaft, but they did work into Stanley Bros No.5 Brickyard and Haunchwood Brick & Tile Co Ltd No.3 Brickyard. They were also allowed as far as the half way point in both Griff Sidings and Griff New Colliery Sidings. (Beyond these half way points track maintenance was the responsibility of the collieries.)

Drawing by Roger West from dimensions taken from the locomotive in February 1964.

During the Second World War the Griff Branch was open for two full shifts daily between 6.00 am and 10.00 pm but by 1950 this had been reduced to a twelve hour period from 7.00 am to 7.00 pm with a 3.00 pm shutdown on Saturdays. This remained the case until the closure of Clara pit. Thereafter the branch opened from 7.00 am to 3.00 pm daily until the closure of No.4 pit. Final closure took place at the end of June 1961, although for about a year previous to this the branch opened three times per week for trip trains from Nuneaton. These were to cater only for traffic to and from the various brickworks until they eventually went over to road transport.

Much of the Griff coal shipped from the canal basin went to the London area for industrial use, also to the nearby Coventry Power Station. The work of loading the canal narrow boats at the basin was never modernised and until the end was performed by a gang of from six to eight men armed with shovels. A narrow boat, when fully loaded, conveyed about 30 tons of coal. By the late 1950's coal traffic on the canal was considerably in decline and it eventually reached the position where only two or three boats were being loaded per week. On the rail-borne side much domestic coal went to London and the South as Griff coal had a high reputation for many years. Industrial coal went to LMS motive power depots and users such as Alders (Tamworth) Ltd Paper Mills and Hams Hall and Nechells Power Stations. Some was also sent to Coventry Power Station to augment that conveyed by canal. One regular customer for very many years was the Oxfordshire Ironstone Co Ltd and up to closure of both pits six wagons of best loco coal were despatched each week for use at Penhill Farm and Wroxton sheds. Needless to say, the local brickworks also used Griff coal as it was of good quality and readily to hand.

The final run down of the system was a gradual one. Clara pit was closed for coal winding on 28th May 1955 but locomotives remained for several months after this, working daily on landsale and canal wharf duties. This continued until September 1956 and by the end of that year most of the track and sidings at Clara and on the Griff New Colliery Branch had been lifted except for one through line which was left in from the colliery yard down to the BR branch for emergency use. Modernisation had previously been planned at the pit but was never implemented due to the Second World War intervening. The steam winding engines were therefore retained to the last. Although coal reserves were exhausted the life of the pit could have been extended for another five or six years if the coal directly underlying Arbury Hall had been won. A public enquiry was held in respect of possible damage to this historic building from subsidence and the NCB's application to work these reserves. was overruled.

Stanley Bros No.5 Brickyard at Bermuda closed down during the late 1950's, mainly because some new clay workings proved to be of unsatisfactory quality and after this time use of the Griff New Colliery branch ceased entirely and the remaining track quickly became taken over by nature.

A new engine shed was opened at No.4 pit early in 1956, and subsequently the old shed had the outer entrance bricked up so that it could be used as an extension to the fitting shop. The new shed (Grid Reference SP348906) was a two road brick building erected on the site of the old wagon repair shop: it was capable of holding two engines. After this time all light wagon repairs were effected in No.4 pit yard but for heavy repairs internals were sent to private concerns including Wagon Repairs Ltd, Burton-on-Trent and W.E. Dinham & Co, Stafford. Following closure of Clara landsale the No.4 engine took over the working of the remaining canal basin traffic which usually amounted to two trips per day between No.4 pit and the basin. In later years the favoured engine was SUCCESS although during the pit's final years she was joined by GOOD LUCK, as already related. The closure of No.4 pit on 22nd July 1960 resulted in the transfer of SUCCESS and (eventually) GOOD LUCK to Haunchwood Colliery. It also brought to an end the long chapter of coal mining in the Griff area.

Between November 1963 and February 1964 all the remaining lines, both NCB and BR, were lifted by a firm of contractors working from Stanley's Sidings to Griff Junction. Today the sites of both collieries are in use as Trading Estates and some of the old pithead buildings still remain as a reminder of the former scenes of heavy industrial activity. The course of much of the old track can still be traced fairly easily but development schemes are being planned and a start has already been made on filling up the cutting of the ex LNWR branch between Heath End Road and Croft Road. The Haunchwood Brick & Tile Co Ltd No.2 Brickyard on Heath End Road, closed for many years, was finally demolished between 1970 and 1972 and is now the site of a new housing estate. The same company's No.3 Brickyard has likewise vanished from the scene, being closed in the mid-1960's and now demolished: it is also being developed as a housing estate. Stanley Bros Ltd No.5 Brickyard, although closed in the late 1950's was only demolished as recently as the summer of 1972 and was one of the sites in the Midlands where illegal cyanide "dumping" took place in recent years! The railway signal box at the former Griff Junction still remains, known now simply as Griff and acting solely as a "fringe" box for the Nuneaton Trent Valley power box scheme. The Griff box also formerly controlled access to sidings at the crushing plant of the Griff granite quarries of William Griffiths & Co Ltd but these sidings, little used for some ten years previously, were taken out in January 1964.

In conclusion I wish to thank Ray Fox, Eric Tonks and Rodney Weaver for assistance with this article. Certain items of information concerning locomotive transfers before and after Griff ownership have been taken from Society records.

Summary of locomotives

|

Name or Number |

Type | Maker |

Works Number |

Date | Cylinders | Wheel Diameter | |

| CREWE | 0-4-2ST | IC |

Bury, Curtis & Kennedy |

- | c1840 | 14½in x 22in | - |

| SWALLOW | 0-4-0ST | OC | Black Hawthorn | 174 | 1873 | 12in x | 3ft 1½ in |

| KNUTSFORD | 0-6-0T | IC | Sharp Stewart | 3471 | 1888 | - | - |

| GOOD LUCK | 0-6-0ST | IC | Hunslet | 498 | 1890 | 13in x 18in | 3ft 1in |

| BRITANNIA | 0-6-0ST | IC | Hunslet | 222 | 1879 | 13in x 18in | 3ft 1in |

| BOBS | 0-6-0ST | IC | Manning Wardle | 1102 | 1889 | 13in x 18in | 3ft 1in |

| SUCCESS | 0-4-0ST | OC | Andrew Barclay | 1167 | 1909 | 14in x 22in | 3ft 5in |

| COWBURN | 0-4-0ST | OC | Hunslet | 544 | 1891 | 13in x 18in | 3ft 1in |

| 75010 | 0-6-0ST | IC | Hunslet | 2859 | 1943 | 18in x 26in | 4ft 3in |

| 70211 | 0-6-0T | IC | Hudswell Clarke | 1102 | 1915 | 16in x 24in | 3ft 9in |

'SMART RAILWAY WORK. - The Common Council of Middleton, Ohio, on November 29 granted the Middleton and Cincinnati Railway the right to carry their line across Sixteenth Street. No sooner was the permission given than the work commenced, scores of men being on the spot at midnight. The following morning a committee of the citizens armed with an injunction restraining the railway authorities from proceeding with the work were astonished to find the rails laid and the road in complete working order.' ("Iron, "2nd December 1892. - KPP).

"The Briansk (Russia) Works' balance sheet up to December 1891, shows a net profit of 90,675 roubles against 1,016,737 roubles in the previous year. The directors attribute this difference to the ... transfer of the manufacture of rails from Biejitza to the Alexandra Works [and the] development of the installation for the construction of locomotives at Biejitza ... Since the commencement of the present fiscal period the Alexandra works has been producing rails in large quantities and on favourable conditions, and the Briansk establishment is building locomotives, the sale of which will assure large profits

" Iron, " 29th July 1892. - KPP)