| THE INDUSTRIAL RAILWAY RECORD |

© APRIL 1969 |

STAR PATENT FUEL WORKS

L. I. HEATH and F. A. JENKINS

The first patent fuel works in Cardiff, the Crown Patent Fuel Works at Maendy, was built in 1846 under patents taken out by H. Walker Wood. Small coal (at that time otherwise unusable) was heated in cast-iron retorts similar to those at a gasworks, and then slowly passed through a worm conveyor. Pitch, ground to a powder, was then sprinkled on it by hand as it emerged, the mixture being then shovelled into vertical pug mills which were heated by encircling flues. The heated mixture descended into hoppers and from these it was fed by hand into 28lb or 56lb moulds for compression. A smaller hydraulic ram ejected the blocks from the moulds, after which they were placed on a barrow and wheeled away.

A second fuel works, the Anchor Patent Fuel Works Ltd., was opened about 1866. The ordinary French process, mechanically perfected, was used and probably no better fuel has ever been made. However, both this process and Wood’s were extremely slow and costly because of the number of men required. Both had the added disadvantage that neither produced a brick capable of being stockpiled for any length of time without losing some of its calorific power. This was overcome in 1874 when T. E. Heath (an employee at the Crown Patent Fuel Works) perfected the "Dry Heat" method of manufacture in conjunction with his son (T. E. Heath, junior) and an engineer named Thomas Evens (not Evans). Heath approached the Crown Works directors for a loan to finance further research, but when this was refused he left the firm, convinced he could produce his own patent fuel more cheaply. Having acquired a loan he was able to start the Star Patent Fuel Works and these were erected in 1874 alongside the Crown Works on a site taken over from Daunford’s Ironworks where chains and anchors had been made. The Works prospered from the start and in 1887 a limited company was formed. (According to our records The Star Patent Fuel Co Ltd was registered on 21st February 1887 to acquire the Star Compressed Fuel Works at Cardiff, formerly the Maendy Ironworks. - Hon Eds). Most brands of patent fuel were made by using steam heat to melt the pitch (pitch being the residue after distilling coal tar) but hot air was used in the Star process. Other makes tended to become porous on cooling whereas the Star briquettes remained as made and therefore did not absorb moisture and crack with frost. They measured 11in x 7in x 7in and weighed approximately 22½lb (a hundred briquettes to the ton).

In the early days all traffic (coal coming in from pits in the Rhondda and Aberdare valleys and briquettes going out to the docks) was conveyed on the Glamorganshire Canal. The Star Works built up a fleet of some forty barges and usually had about ten more on hire; they were maintained in a shed between the loading area and the southern boundary wall where before 1887 the Company had built two barges named JUBILEE and JUBELA. Loading of barges was effected by means of an overhead gantry system direct into the works. Each gantry was actually one long wire rope wound round sheaves to form four parallel ropes (like a belt conveyor) on which the fuel blocks were placed.

Complete dependence on canal transport was broken in the early 1880’s when rail access was provided, and this enabled the Company to purchase a wider selection of coals from pits not served by the Glamorganshire Canal. The siding which connected the Crown Works and the Star Works to the Taff Vale Railway main line was controlled by Maendy signal box. Full wagons of coal were left on the Taff Vale siding and drawn off as required. Once inside the works the Taff Vale bull-head rail gave way to flat-bottom light rail of about 75lb/yd (except at the coal tip where it was 100lb/yd) which was secured to wooden sleepers by dogspikes. Crossings and points were made in the works, the angles being between 1 in 6 and 1 in 4.

Because of the light nature of the track horses hired from a Mr Pidgeon were employed to shunt wagons in and around the works, and although a small locomotive was considered in the early days the thrifty owners decided otherwise on the grounds of economy. However, this question came up again as rail traffic grew, and when I. M. Heath saw a Chaplin "coffee-pot" locomotive at the Tintern Tinplate Works he realised that this type would be quite suitable for the Star Works. An advertisement in 1892 by Charles D. Phillips of a Chaplin locomotive for sale led to its purchase from J. F. Wake, a Middlesbrough dealer, in March 1892 for £125. This led to some exchanges with Mr. Pidgeon who was most indignant when told that his horses were no longer required. He maintained that the locomotive could never do the work as well and would be less reliable. Fortunately this proved to be far from true as the Chaplin was a most useful acquisition. Although fuel blocks continued to be sent away in Star barges until the works finally closed, coal came in by rail almost exclusively.

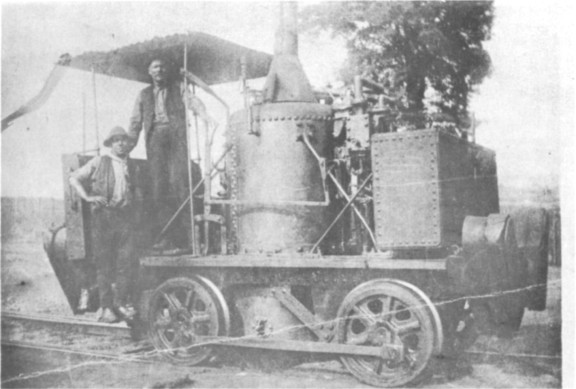

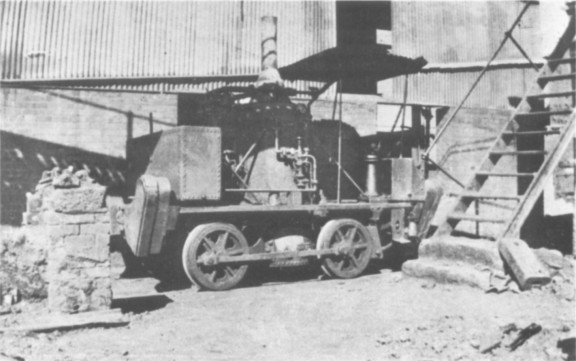

The Chaplin locomotive, which became No.1, was quite small and light. It was easy to maintain and the gearing was admirable for constantly stopping and starting; the slow speed also allowed for greater safety for workmen in the yard. (About 120 people were employed in the works with another hundred at the docks loading ships.) The success of No.1 both in efficiency and reliability led the directors to consider obtaining another like it in order to allow continuous working when the planned factory extensions came into operation. And so in 1901 a similar advertisement by Phillips led to the purchase of the second Chaplin from J. F. Wake (at Darlington, this time) for only £100 - but it was soon to need repair! In spite of its condition the purchase of No.2 was to say the least timely, for No.1 was in a very bad state due to continuous steaming and was able to move only one loaded wagon at a time. It was decided that extensive overhauls would be necessary and two new boilers were bought from Holdsworth. In these boilers the centre flue was approximately 6in in diameter and the surrounding six fire tubes about 3in in diameter; a conical smokebox covered the tubes. Unfortunately, before No.1 had been repaired, No.2 had to be withdrawn as well for temporary repairs to be carried out. This of course meant no motive power and horses were hired until No.2 was back in service. Once No.1 was serviceable again, No.2 was withdrawn for a complete overhaul. At this time the coal bunker on both locomotives was upended so that patent fuel blocks could be carried; previously the storage capacity had been rather limited and stops for refuelling had delayed shunting.

The two locomotives differed somewhat in detail. No.2 had disc wheels with bushed siderods and cottered big ends to the connecting rods, while No.1 had spoked wheels, cottered siderods and connecting rods with marine big ends. The connecting rods of both were forked; the piston rods being prolonged and working through bushed guides in a bracket fastened to the boiler. Another interesting point was that though both locomotives had hand brakes with wooden blocks, they differed in layout. No.1 had the brake handle and regulator on the left hand side with the reversing handle on the right, but No.2 had all these fittings on the right, Elementary weather protection was provided on both locomotives after purchase. No.1’s canopy had rusted away and a new one of corrugated iron was fitted similar to the one put on No.2, but how much shelter these rather flimsy affairs gave is open to doubt. Other detail differences were that No.1 had a waist-high cab back-plate whereas No.2 had only handrails. No.1’s beams were of cast iron with wooden block buffers and had two drawhook sockets at the rear (one above the other) but only one at the front; No.2 was similar at the rear but had a wooden beam at the front. New cylinders were machined for both locomotives about 1918 by L. I. Heath (grandson of the founder) and new eccentrics were fitted about the same time. The gearing of No.1 and No.2 was similar with about a 2½ to 1 reduction; there were thirteen teeth on the steel pinion on the crankshaft, and thirty-one teeth on the cast-iron gearwheel on the axle. The leading dimensions were: - vertical cylinders - 6in diameter, 12in stroke; wheels.2ft 6in; wheelbase - about 5ft 4in; weight - about 7½ tons.

Two views of No.1, the first and last locomotive to be used at the works. Upper photo is a copy of a faded original by courtesy of Mr. G. Alliez, the lower being a more recent view. (L. I. Heath)

About a hundred wagon loads of coal and pitch arrived daily. The wagons were weighed one at a time at the weighbridge where there was just sufficient room for the Chaplin to draw forward to the buffer stops: after weighing" the wagons were propelled (generally three at a time) to the coal tip. Before the new factory was constructed alongside the original one in 1901 there were but three internal sidings alongside the tip where the three main types of coal were stored. From here the wagons were collected and taken either to the coal tip of the old factory, or to the coal and pitch storage loop siding where the contents were tipped into barrows and pushed into the works. In 1901 several sidings were extended while the old coal and pitch storage loop became the New factory coal tip siding; from it a line led into a new locomotive shed. Three other new sidings between the main line and the new factory are of interest as they ran alongside platforms some 3ft high. Pitch stored here was taken into the factory on the 2ft gauge system laid down in 1901. Using human motive power this system was constructed of flat-bottom rail and employed turntables instead of points wherever practicable; in those places where narrow gauge rails passed over the standard gauge they were swung to one side when standard gauge wagons required to pass.

The narrow gauge system also provided the means of removing ashes from the two boiler houses to the bottom of the yard. Here the trams were run up a short incline to the belt store where the ashes were tipped down the bank and later sold to local builders. An unusual feature of the short incline was that the rails leading down from the belt store had measured markings so that belts could be unrolled down the track and cut to the required lengths. For a few months in 1909-1910 a narrow gauge line ran on trestles seven feet high between the canal and the storage area. Trams were loaded by elevator from barges and the contents were tipped at any place en route or directly into standard gauge wagons. Where the trestles crossed any of the standard gauge lines a balance bridge was used which could be lifted as required. There were about twenty narrow gauge trams of foreign build supplied by Boiling & Lowe, agents, London; measuring about 6ft by 4ft 6in the U−shape side-tip bodies held one cubic yard. Nothing larger could be considered because of the sharp curves and the closeness of several buildings to the track. Two 4−wheel wooden bogies built by the Company were used for moving about the works large items of machinery; one was built new, but the other was an underframe converted in 1917 to a flat-top platform. So that coal could more easily be tipped through a hole in the boiler house wall a very low-slung narrow gauge tram was built at the works in the 1920’s.

The early standard gauge wagons for internal use are thought to have had buffers at one end only. They were replaced about 1906 by a set of second-hand wagons obtained from A. W. Phillips, a coal merchant and exporter of Cardiff. The name "Phillips" emblazoned on the sides was not painted over for some years, and on one occasion an over-zealous Phillips employee complained to Mr. Heath about the time some persons took to return other people’s property! No heavy maintenance was carried out on these wagons as they were in continual usage, and before the end of the First World War they were in an appalling state of repair. Late in 1918 five brand-new wagons were obtained as replacements at £80 each from the Cambrian Wagon Works Ltd., East Moors, Cardiff; they were wooden side-tip wagons of standard "Manchester Ship Canal" pattern as used by railway contractors, and lasted until the works closed.

The works were very dependent on overseas orders and the First World War marked the beginning of its decline. The outbreak of hostilities meant breaking ties with many customers including the Austro-Hungarian Navy’s patent fuel bunkering depot at Trieste. During the War output was maintained at a reasonable level, patent fuel being directed to customers abroad (especially the French railways) by the Admiralty. But many foreign markets were lost to competitors, or the customer found a substitute fuel. The gradual decline in trade can be visualised by the fact that after the War the daily output fell from 1,000-1,100 tons (or fifty barge loads) to 700 tons. Even worse was to follow and in the 1920’s the growing world depression caused an almost total loss of markets. Barge traffic was non-existent for weeks at a time, and with little or no rail traffic the Cambrian Wagon Works unsuccessfully asked whether they might hire one of the Chaplins. One morning in this period of spasmodic working No.1 broke down and, as No.2 was not serviceable a locomotive was borrowed for the first time to do the afternoon’s work. Although the wagon works of Hall, Lewis & Company adjoined the Star Works, there was no direct rail connection and the Black Hawthorn 0−6−0 saddle tank EML YN had to travel over a hundred yards or so of main-line siding.

In December 1927, with no immediate prospects of a revival in trade, the Star Works and some of its rivals like the Anchor Works decided to close down. Part of the site was taken over by a furniture factory, whilst the north end was acquired by the adjoining Powell Duffryn wagon works. But No.1 was in fact used about 1930 to shunt wagons of scrap to the mainline sidings. A burst in the canal bank near Cilfynydd in 1915 had left the canal only partly operational - the section between Pontypridd and Abercynon was closed - and no buyers could be found for the Star boats which gradually rotted away. The five wagons were in such a dilapidated condition that they were only fit for scrap, and when dismantling was completed in 1930 the Chaplins themselves were broken up and despatched to the scrapheap.

Old railway vehicles occasionally end their days as holiday chalets, and one is tempted to think that the designer of the Chattenden & Upnor Railway brake vans was thinking to the future when he incorporated such charming bay windows.

The picture was taken in August 1954 at Lodge Hill, by G. Alliez.