| THE INDUSTRIAL RAILWAY RECORD |

© JUNE 1967 |

LOCOMOTIVE PRESERVATION

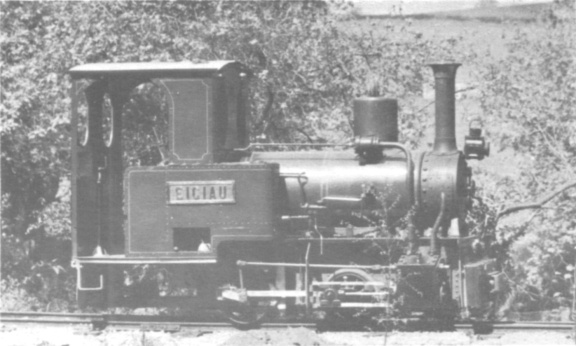

(3) EIGIAU

G. J. MULLIS

Among my many virtues or failings, according to the way one views them, were an almost fanatical fascination for steam engines and an inborn liking for attempting things which, to any normal person, would appear sheer stupidity. In the early days of married life these 'kinks' developed along separate lines, building work finding me plenty of opportunities for the latter and for the former, quite a wide field of operations, one of which eventually brought the two together.

I had gone through all the early stages of "Railwayitis", building myself in the meantime a fairly comprehensive "00" gauge model railway layout. But this seemed more and more like childsplay the further I progressed. Then, while meandering about in North Wales, I spotted a row of narrow gauge engines obviously the victims of old age, the weather and souvenir hunters.

Without having any particular plan in mind, I decided that I must acquire, if not one of those, at least some old narrow gauge engine. This was in September 1962 and it was well into the winter, after visits to all the likely quarries and numerous arguments and hagglings over various engines, that I at last became the owner of EIGIAU, one of the best of the Bethesda engines.

Steam amongst the sycamores; September 1964 (M. H. Billington).

Built in Germany in 1912, EIGIAU

worked for many years at the Penrhyn Slate Quarry. The upper photograph was

taken at the quarry in 1951, and the lower photograph shows the locomotive at

Droitwich in September 1964.

Photographs by F. Jones (upper) and G. J. Mullis

(lower).

There was just one small snag still to be overcome. Getting EIGIAU from North Wales to Droitwich! After exploring the possibilities of British Railways and various road haulage firms, I decided to use a local haulier and my own gang of men. Just to add to the complications, the quarry had been frozen up for weeks and life there had virtually ceased for the time being - not surprising with a 2in. coating of ice on everything;

But, having secured the prize, I wanted it on my own doorstep. So, despite well meant advice to the contrary, we set out to get it - and did so, in three weekends. On the first (26 January 1963) we removed all the bits and pieces - cab, tanks, chimney, side-rods, etc., leaving the main part including the well-tank which was full of solid ice to the second. On the third and final trip we collected the oddments and tackle - mainly a stout sheerlegs. The second return journey alone took 82 hours (21.00 on 2 February to 05.30 on 3 February) which included changing a wheel.

Back at home, I had already made provision for EIGIAU by enlarging the access to one of the outbuildings. As the job of stripping and re−assembling progressed, various modifications to the building had to be carried out, including, at a very early stage, the provision of a stout improvised crane to replace the pulley block and tackle which at times seemed in danger of pulling the building down. Later I carried out a major 'face-lift' to give EIGIAU a respectable shed and workshop complete with a smoke canopy which, by then, had become a 'must'.

The work of stripping and rebuilding occupied all my spare time from January 1963 to June 1964 apart from a break of four week-ends when, with the assistance of three or four willing helpers, I laid my 120−odd yards of track. (The rails, ex−N.C.B. surplus, are 45 lb. per yard spiked to standard halved ex−B.R. sleepers, ballasted with 112 in. crushed limestone.) I tried getting the many bits and pieces from the makers, Orenstein & Koppel of Germany, but failed and so I had to rely on local talent and improvisation to get as near as possible to the originals, cursing the souvenir hunters in the meantime. The firetubes were rotten and had to be replaced and it was during the removal of the old tube ends that I had quite an amusing experience.

I had a number of voluntary assistants at various times but on this occasion only my very young son, Neville. None of the standard or improvised pullers being of avail - many of the ends had been almost riveted in - I decided to use a small cutting pipe to nick the ends, a method I found very effective if done with care. The front end was comparatively easy; the snags came with the back. The boiler was propped up on baulks of timber and I was kneeling inside the firebox with my feet sticking out behind, a difficult enough position to get into but, to complicate matters, Neville took up a grandstand position sitting on my legs and watching through the firedoor opening. And then it happened, the splash from the pipe set fire to my overalls; By the time I had got Neville 'off my back' and crawled out of the firebox, my trousers and overalls were a write−off - or burn off - and I almost needed re−tubing;

The retubing of EIGIAU was the biggest job that had to be done but it proved to be quite straightforward compared with some of the less important jobs. The lagging and covering of the boiler was quite tedious. I used mahogany strips for the actual lagging. Holding these in position while subsequent pieces were cut round the dozens of obstructions was bad enough. but to hold a complete ring of them and secure the cover plates at the same time needed more than a little patience and improvisation. The local blacksmith was very useful for many of the smaller jobs such as building up the bottom part of the smokebox which had rotted away, mainly through the weather.

The only obvious non−standard part on EIGIAU is the copper flare to the chimney, the original being painted iron. Such things as safety-valves have little originality unless provided with a cover and as EIGIAU's, which are replacements, are mounted naked on top of the dome, they appear little different from the originals.

Getting the valve setting correct was very awkward and I had upset this quite a lot by having to extend the rear spring 'push rods' in order to cure a nasty back end droop, the cause of which I was unable to trace.

EIGIAU is now painted in standard G.W.R. green with red lining, maroon underframes and black wheels. The nameplates, also new and cast in my own foundry from patterns made from photographs of the originals, are in polished brass with red background.

| Gauge | 1ft 11½in | Heating surface (Firebox) | 15sq ft |

| Cylinders | 6½in by 12in | Heating surface (tubes) | 111sq ft |

| Wheel's (diameter) | 1ft 7½in | Grate area | 3¼sq ft |

| Wheelbase | 3ft 4in | Tractive effort (60%) | 2240lbs |

| Water | 104 galls | Length over buffers | 12ft 10in |

| Coal | 6½ cwts | Weight (empty) | 5ton 6cwt |

| Pressure | 176 lbs/sq in | Weight (loaded) | 6ton 11cwt |

EIGIAU fans are welcome to call, but Mr Mullis asks that intending visitors should write him beforehand (S.A.E. please) to arrange a suitable time. The address is:- Mr G.J. Mullis, Coley Pits Farm, Wychbold, Nr Droitwich, Worcs.

******************************************************************

About the end of July a railway collision occurred near Ellesmere Port, which caused the loss of three lives. Through culpable neglect, two engines, the DEAL and the RHYMNEY, with their trucks, smashed into one another. The DEAL conveyed the trucks in which the men went down the line to their work. The driver stated that there were six people besides himself and the fireman on the engine. Five jumped off when they saw the collision was inevitable, but three remained on and were all killed. (History of the Manchester Ship Canal, Volume 11, 1907.)